Control method of isg motor intervening in dual-clutch automatic transmission shifting

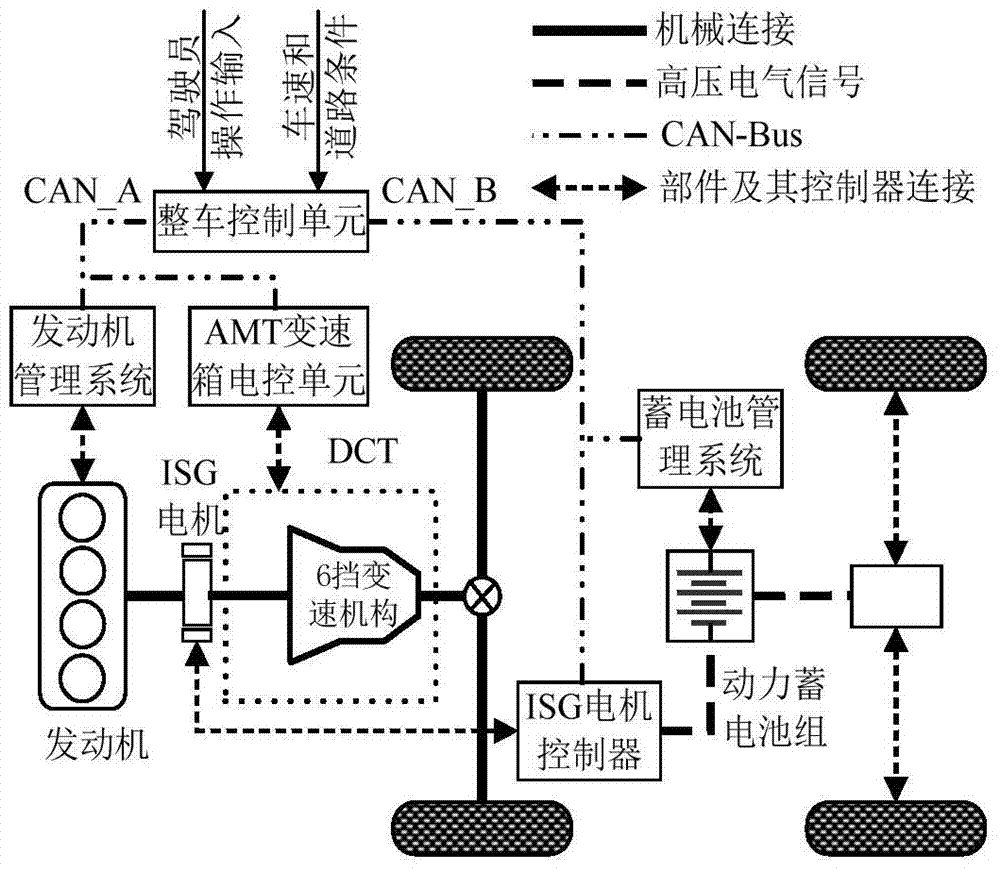

A technology of automatic transmission and control method, which is applied in the direction of motor vehicles, control devices, hybrid vehicles, etc., can solve the problem of insufficient consideration of the vehicle dynamics during the gear shifting process, overcome the problem of transient emission deterioration, and improve fuel economy , Overcome the effect of torque response lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

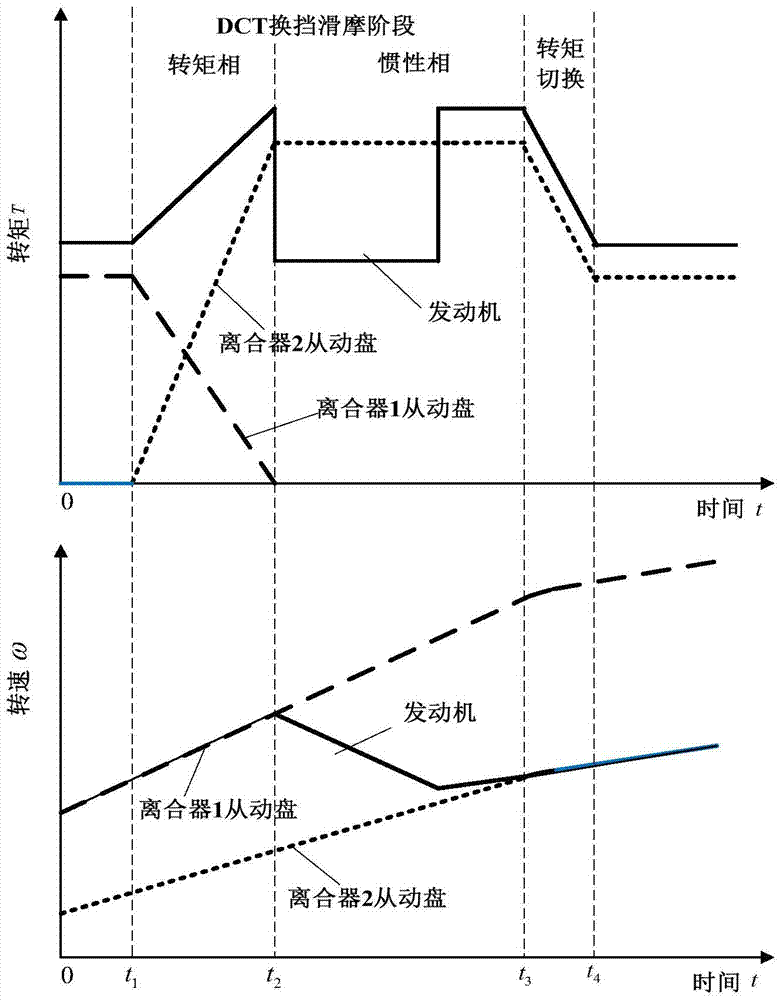

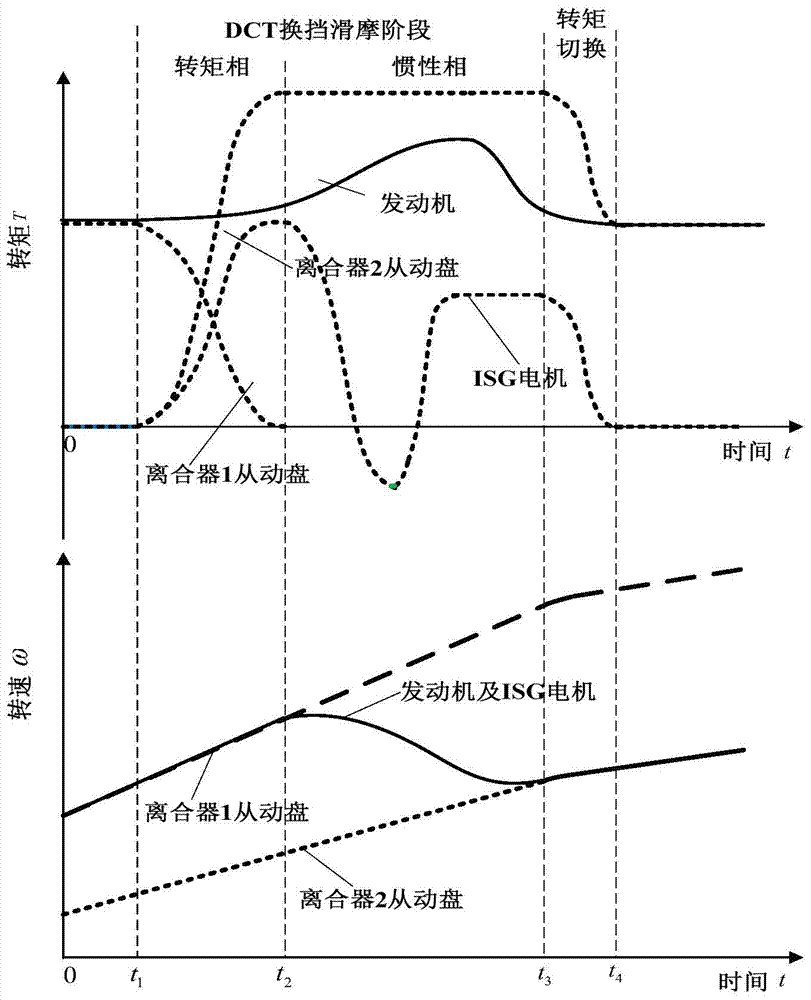

[0034] The calculation of the synthetic torque of the power source and the equivalent transmission torque of the clutch of the present invention is based on the eight-degree-of-freedom dynamic equation of the DCT shifting slippage phase and the use of the transmission ratio relationship to simplify the two-degree-of-freedom shift dynamic model:

[0035]

[0036] Where Are the equivalent moment of inertia and equivalent rotational viscous damping coefficient equivalent to the output shaft of the transmission, K on , K off Respectively, they are the magnification factors that are equivalent to the transmission output shaft of the transmission torque from the engaging clutch and the separating clutch.

[0037] The DCT shifting process is essentially the shifting process of a relatively independent continuous variable dynamic system, which is specifically manifested as a dual-clutch working state switching process in which the engaged clutch is separated during the shifting process an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com