Full-open type hinge device for cabinet

A fully-opening, hinged technology, applied in the direction of folding panels, door/window accessories, hinges with pins, etc., can solve the problems of increasing the cost of use, unfavorable cabinet sealing, affecting the appearance, etc., to achieve a simple structure, avoid the overall Disassembled, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

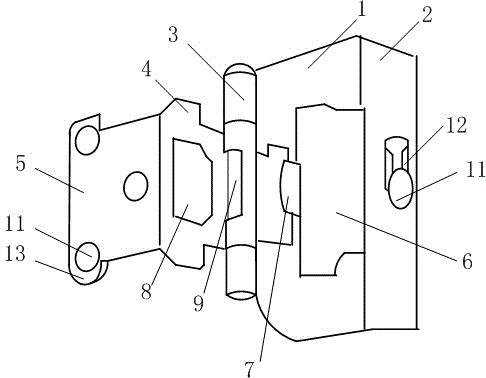

[0016] Such as figure 1 A full-open hinge device for cabinets shown includes a frame positioning assembly 1, which is different in that: in order to facilitate installation with the edge of the cabinet, a main hinge is provided at one end of the frame positioning assembly 1 Fold edge 2. The length and angle of the main folding positioning side 2 can be adjusted on site according to the edge style of the cabinet. At the same time, the other end of the frame positioning component 1 is provided with a connecting shaft 3 for realizing the opening and closing of the hinge. Moreover, the connecting rotating shaft 3 is connected with the door panel connecting block 4 at the same time, and the auxiliary folding positioning edge 5 is distributed on the door panel connecting block 4 . Correspondingly, through the existence of the auxiliary folding positioning edge 5, the door body to be installed later can be effectively connected to realize the positioning of the door body and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com