Replaceable lubricating oil applying device for bearing

A technology for applying lubricating oil and bearings, applied in the direction of engine lubrication, lubricating parts, engine components, etc., can solve the problems of increasing equipment investment costs, wasting lubricating oil, and restricting usability, saving economic costs and reducing labor intensity. , The effect of preventing external splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

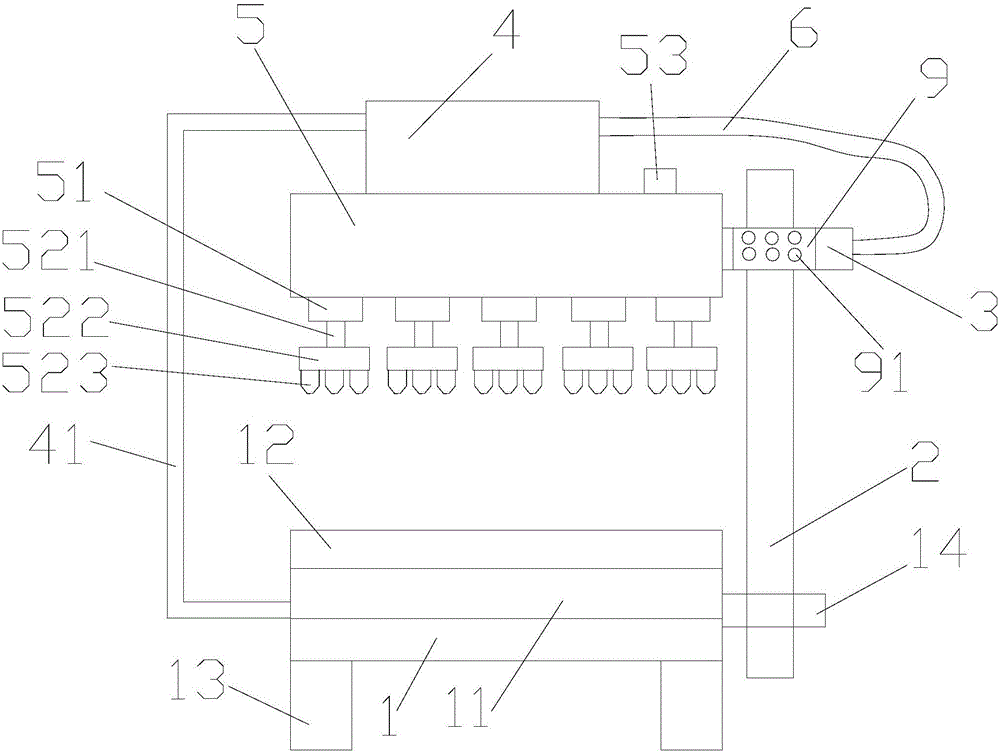

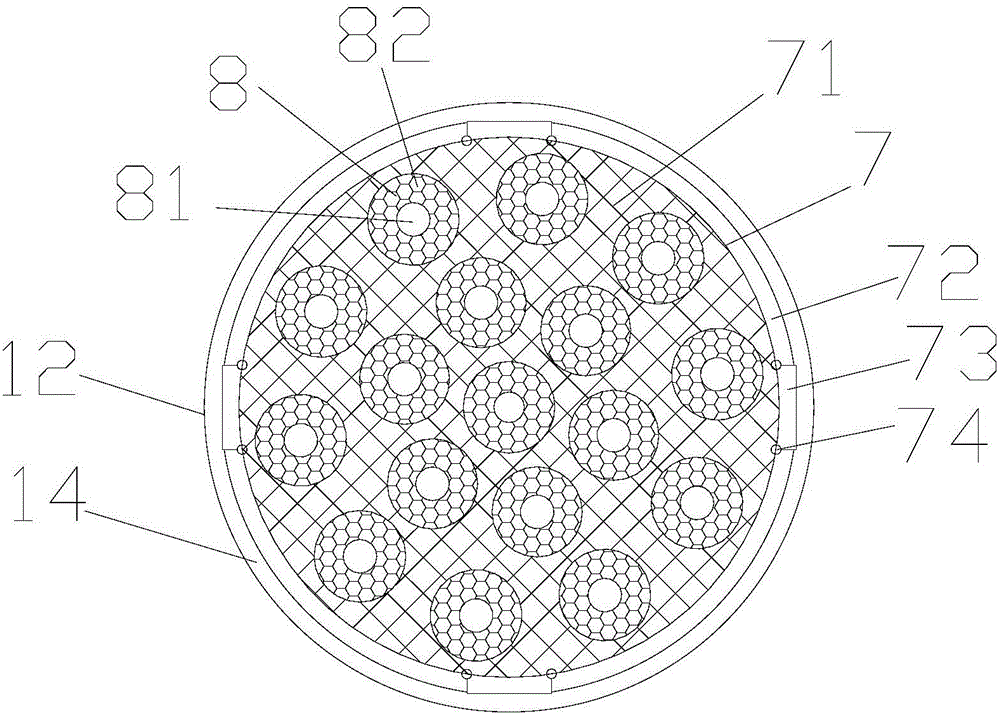

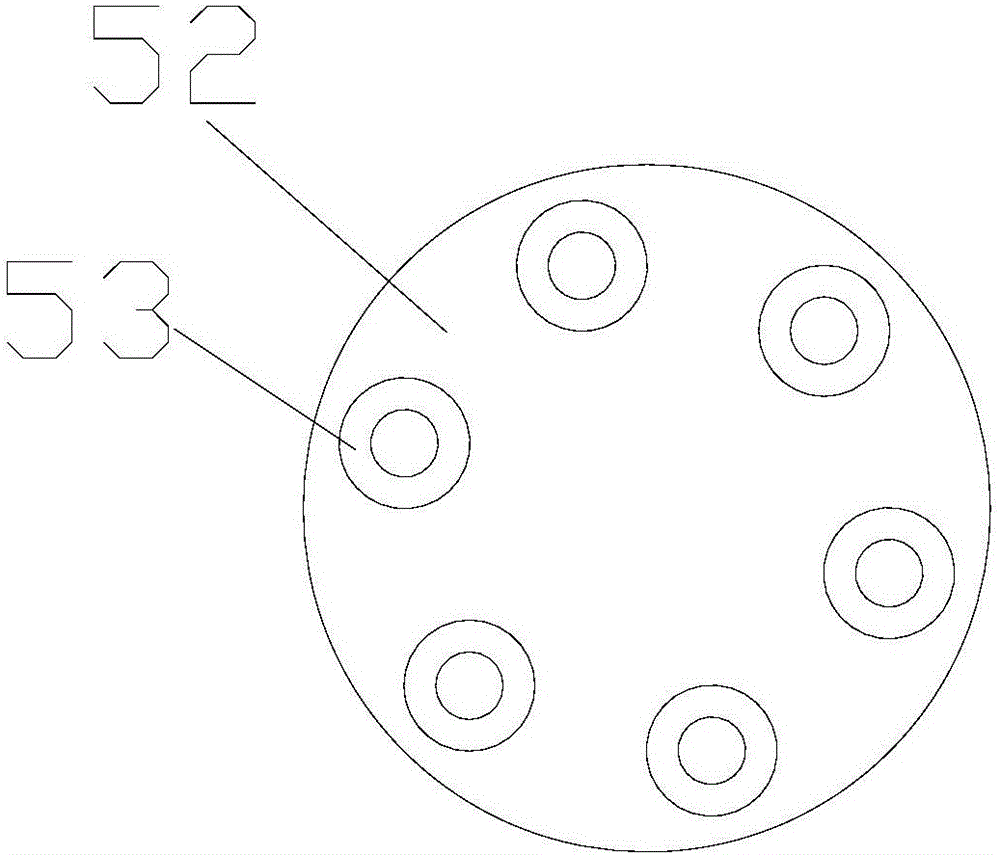

[0017] refer to figure 1 , figure 2 , image 3 and Figure 4 , a replaceable lubricating device for bearings of the present invention, comprising an oiling tank 1, a sliding rod 2, a sliding sleeve 3, a negative pressure fan and a power supply room 4, an oil storage tank 5, a ventilation pipe 41 and a bearing placement plate 7, Oil tank 1 is also provided with oil return tank 11, oil baffle plate 12, supporting foot 13 and support bar 14, and oil return tank 11 is positioned at the middle position of oil tank 1, and oil baffle plate 12 is positioned at the top of oil return tank 11, and leg 13 supports oil tank 1 , the supporting rod 14 is located on one side of the oil tank 1, one end of the sliding rod 2 is fixedly connected to the supporting rod 14, the sliding sleeve 3 is slidably placed on the sliding rod 2, one side of the sliding sleeve is fixedly connected to the oil storage tank 5, and the upper end of the oil storage tank 5 is fixed There is a negative pressure f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com