A Combined Vibration Measurement Auxiliary Rod

A vibration measurement and combined technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of measuring personnel poisoning, rotating machinery damage, leakage damage, etc., and achieve low cost, weight reduction, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

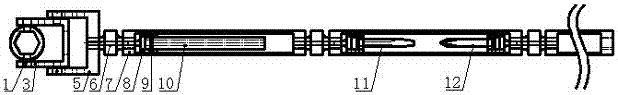

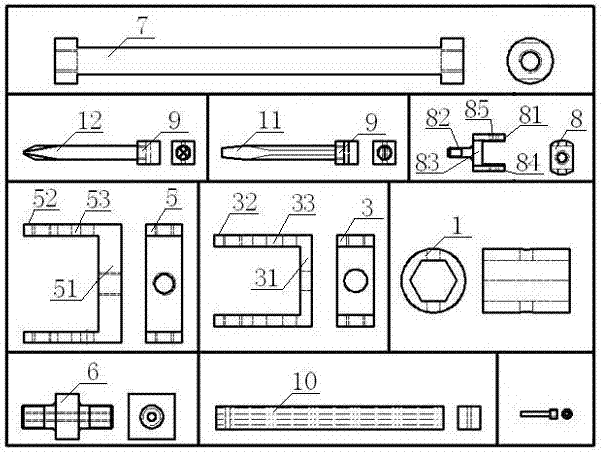

[0033] Such as figure 1 As shown, a combined vibration measurement auxiliary rod includes a sensor fixing sleeve 1, a support seat group, a connecting rod joint 6, and a connecting rod 7;

[0034] The two ends of the connecting rod 7 are provided with internal thread holes; the two ends of the connecting rod joint 6 are provided with external threads that match the internal threads at the two ends of the connecting rod 7, and the two ends of the connecting rod joint 6 are also provided with internal threads hole;

[0035] One end of the supporting seat group is provided with an internal thread hole, and its thread matches the external thread at both ends of the connecting rod joint 6; the sensor fixing sleeve 1 is installed on the other end of the supporting seat group.

[0036] The connecting rod joints 6 and connecting rods 7 are provided in multiple groups, and the connecting rods 7 are connected through the connecting rod joints 6 .

[0037] The set of supporting seats i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com