Cement setting time tester

A technology of time determination and cement setting, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of heavy workload of experimenters and low accuracy of test results, and achieve convenient experimental operation, low cost, and simple design structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

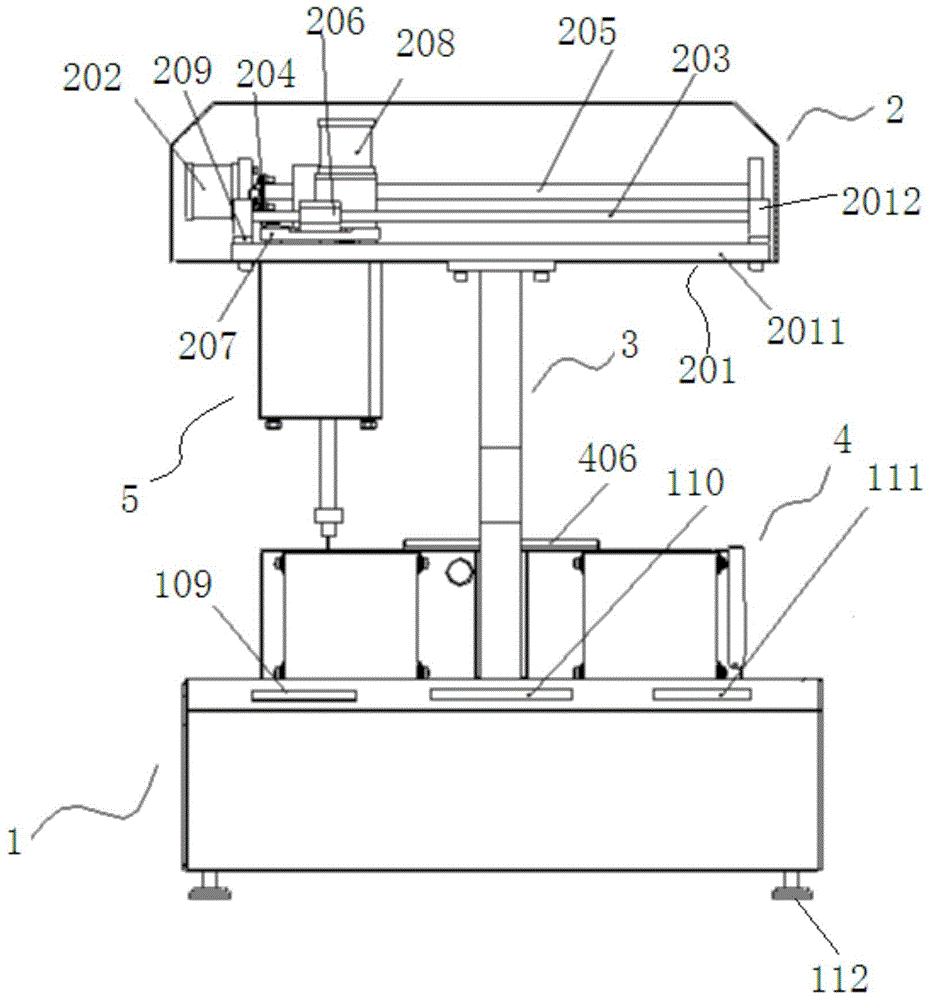

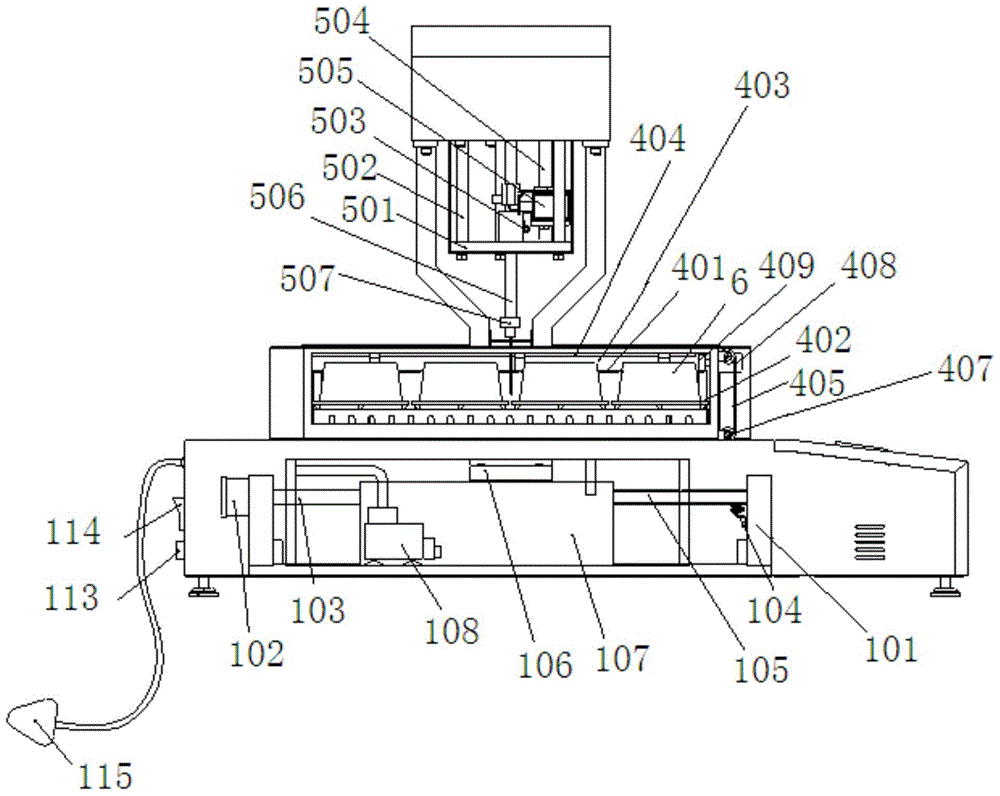

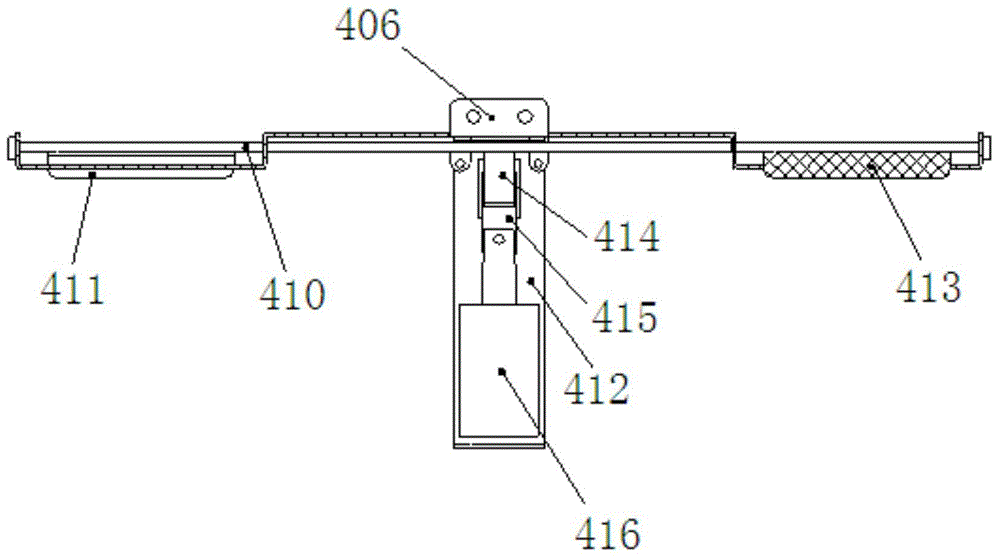

[0015] Such as Figure 1~3 As shown, the cement setting time tester of the present invention comprises a bottom shell 1, a top shell 2, a support body 3, two measuring chambers 4 and a machine head body 5; the bottom shell 1 and the top shell 2 A support body 3 is arranged between them, the top of the support body 3 is fixedly connected with the top shell 2, the head body 5 is arranged at the bottom of the top shell 2, the bottom of the support body 3 is movably connected with the bottom shell 1, and the bottom shells on both sides of the support body 3 Two measuring chambers 4 are respectively fixedly arranged on the body 1;

[0016] A Y-direction component base 101, a Y-direction stepping motor 102, a Y-direction supporting optical axis 103, a Y-direction limit switch 104, a Y-direction ball screw 105, and a Y-direction sliding unit are arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com