Improved method for detecting short trouble of exciting winding of turbonator

A technology of turbogenerator and excitation winding, which is applied in the direction of motor generator testing, measuring electricity, measuring devices, etc. It can solve the problems of increased calculation error of the theoretical value of excitation current, insufficient sensitivity, and unsatisfactory linearity, etc., and achieves improvement. The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

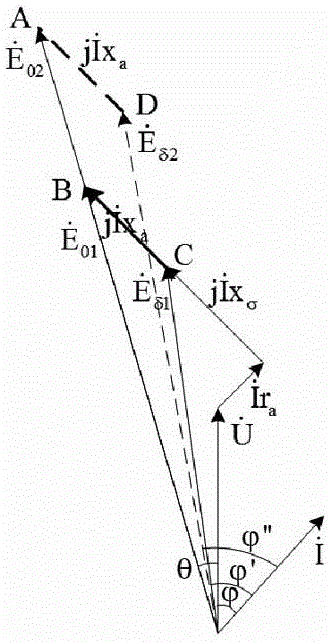

[0038] The electromotive force vector diagram of the turbogenerator in a certain operating state (active power P, reactive power Q) is as follows: figure 1 Shown in the solid line. According to the vector diagram, the expression can be obtained:

[0039]

[0040] According to expression (1), it can be further obtained:

[0041]

[0042] According to formula (2), the electromagnetic power of the generator can be known as:

[0043]

[0044] It is now assumed that when the excitation current of the generator is increased, the stator side θ, The equivalence remains unchanged, and the no-load electromotive force is given by increased to Translate the line segment BC to AD in the figure to determine the air gap electromotive force of the generator can be seen compare significantly increased, and angle of also greater than and angle of The following expressions exist:

[0045]

[0046] Further get:

[0047] P M1 M2 (5)

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com