Mining automatic water drainage device applying carrier wave

An automatic drainage and mine-used technology, which is applied in the field of remote monitoring and mine-used automatic drainage devices, can solve problems such as complex wiring, inconsistent drainage equipment interfaces, and inability to complete real-time interaction of water regime data in underground roadway water tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

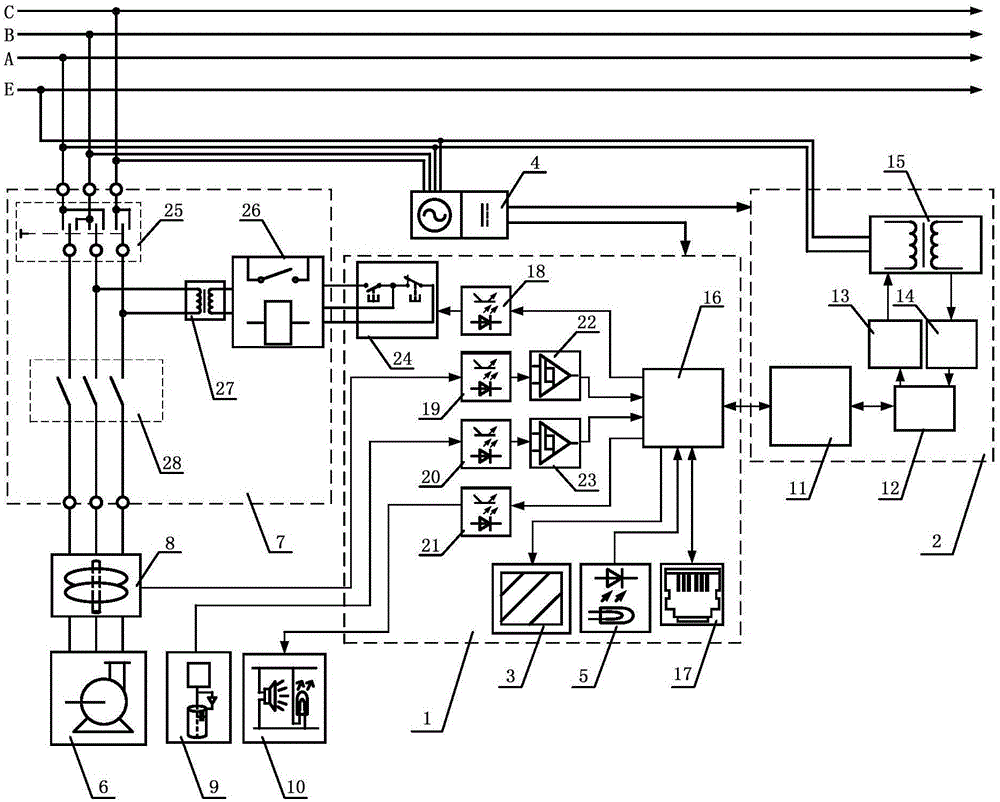

[0015] Attached below figure 1 Further explain the application of a mine automatic drainage device using a carrier wave in the mine roadway automatic drainage, and the working principle of the water regime information collection and application carrier network control process of the present invention.

[0016] According to attached figure 1 In the scheme shown, the underground low-voltage power line is a three-phase four-wire system, which are the three-phase wires of the underground power A, B, and C and the ground wire E. First, connect the three-phase wires of the underground power A, B, and C to the electromagnetic starter 7. The A, B, and C three-phase wires of the underground power after being connected are connected to the mine drainage pump 6, and the start-stop sensor 8 is fixed on the cable between the electromagnetic starter 7 and the mine drainage pump 6 with a fixed card. Then connect the downhole power A, B, C three-phase wire and the ground wire E to the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com