High voltage safety type bus duct cover plate

A safety-type, busway technology, applied in the direction of fully enclosed busbar installations, etc., can solve problems such as unfavorable safety production, failure to meet safety performance requirements, simple structure, etc., achieve firm fixation, improve use effect, and improve pressure-bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

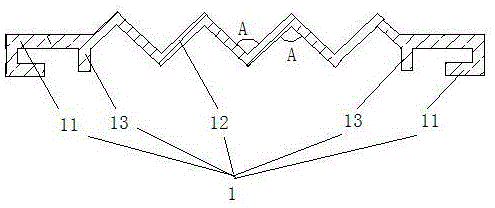

[0010] As shown in the figure, a high-voltage safety busway cover plate includes a main body. The cover plate main body 1 includes a positioning clamping part 11 and a pressure-bearing part 12. The body 1 is an integral structure. The pressure-bearing The part 12 is a zigzag structure, which is composed of a plurality of inclined boards and is an integrated structure. The angle A formed between the inclined boards is 90 degrees; the positioning and clamping part 11 is located at the pressure receiving part 12 Both ends, the cross-section of which is a "C"-shaped structure, the positioning and clamping part 11 is located at both ends of the pressure receiving part 12, and is arranged axially symmetrically with the pressure receiving part 12 as the axis of symmetry; the two ends of the pressure receiving part 12 The bottom is provided with busbar positioning protrusions 13, and the number of said busbar positioning protrusions 13 is two, which is a rectangular protrusion structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com