Paint process for effectively preventing matt oil paint of log door sheet from fading

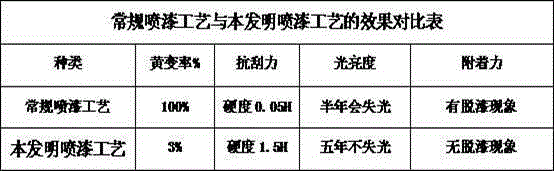

A log and door panel technology, which is applied in the field of paint technology to effectively prevent the matt oil-based paint of log door panels from losing color. It can solve the problems affecting the quality of high-end interior decoration products of log door panels, the paint layer fades, and turns yellow, so as to improve the strength and research and development level. , good gloss retention, yellowing resistance and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of paint process that effectively prevents the matte oily paint of log door panels from losing color, the paint process comprises the following steps:

[0024] Step 1: Process and make the frame and core board of the original wooden door panel respectively;

[0025] Step 2: Spray the frame and core board in step 1 with at least one primer coat;

[0026] Step 3: Carry out the spraying of the color correction paint layer to the frame and the core board which have been sprayed with the bottom paint layer in step 2 respectively;

[0027] Step 4: After the color-repairing paint layer in step 3 dries naturally, a curing agent is added to the color-repairing paint, and then the second spraying of the color-repairing paint layer is carried out again;

[0028] Step 5: In the above step 4, after the frame and the core board of the secondary spraying and repairing paint are dried naturally, the surface paint layer is sprayed;

[0029] Step 6: Embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com