Automatic Feeding Screw Locking Machine

A screw locking machine and automatic feeding technology, which is applied in the direction of motor tools, hand-held tools, metal processing, etc., can solve the problems of inconsistent torque, low assembly quality, low assembly efficiency, etc., and achieve increased stability and progress Give strength, improve installation quality, and improve installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

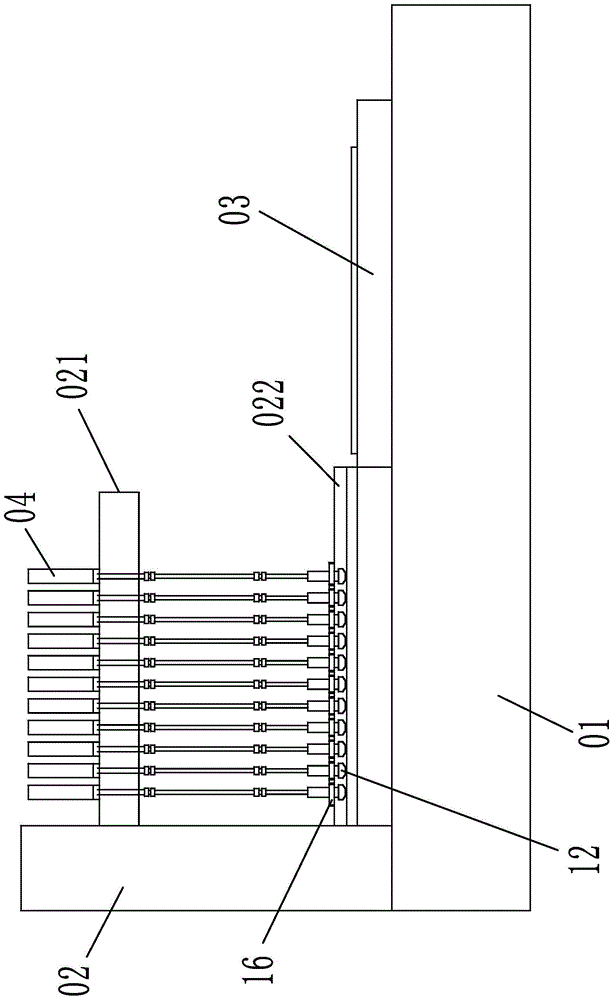

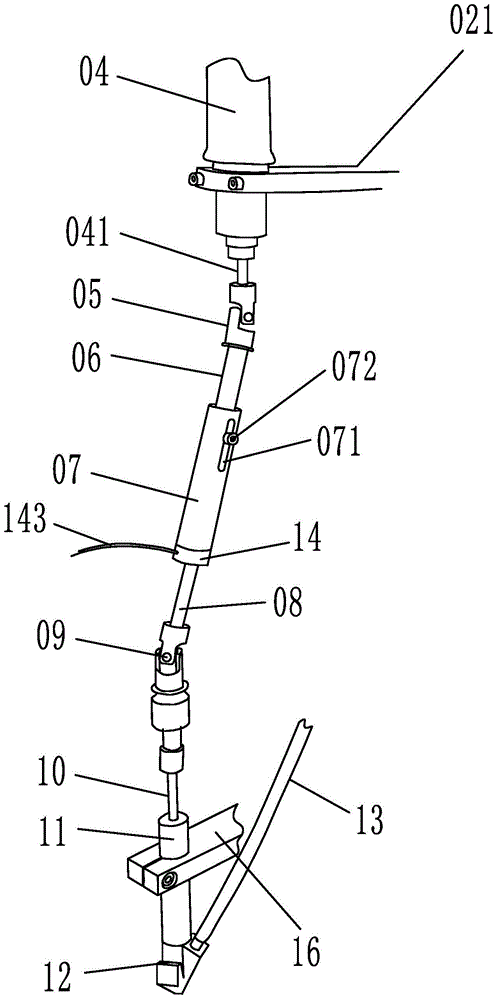

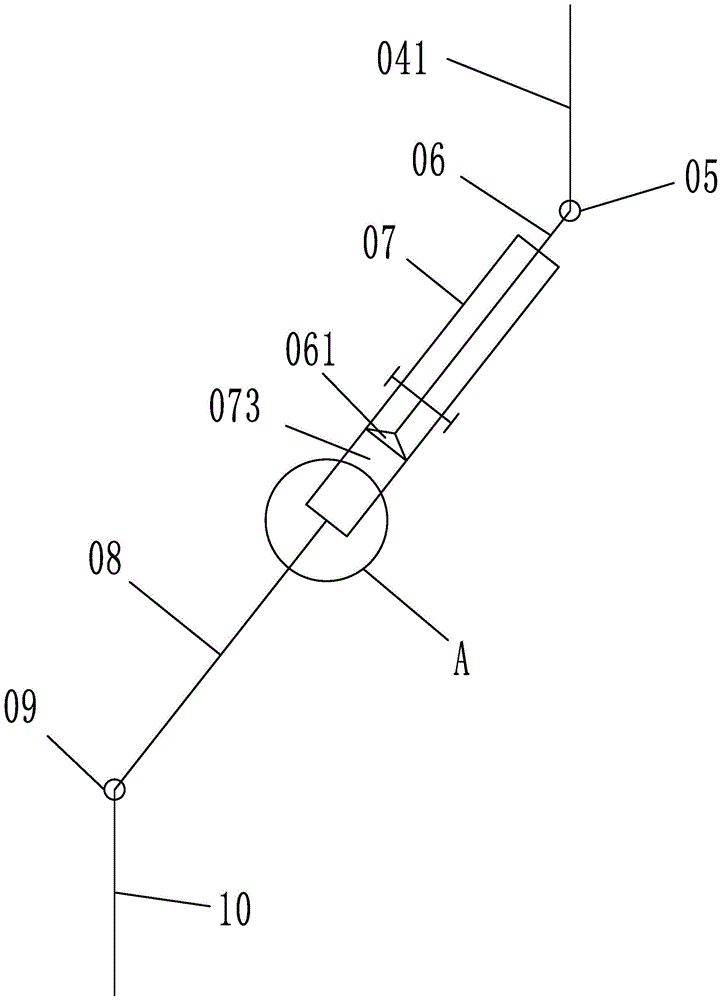

[0025] Embodiment 1: as figure 1 , 2 , Shown in 3, a kind of automatic feeding type screw lock pays machine, comprises frame 01, is provided with feeding system 03 and lifting system 02 on the frame, as Figure 10 As shown, the feeding system includes a guide rail 031 arranged horizontally, a shelf 032 for supporting workpieces, and a driving cylinder 033 for pushing the shelf, and the shelf is slidably connected to the guide rail. The lifting system is connected with the upper lifting frame 021 and the lower lifting frame 022, and the top of the upper lifting frame is provided with several motors 04 arranged longitudinally, the driving shaft 041 of the motor is connected with the first coupling 05, the motor driving shaft and the telescopic shaft The angle between them is 160°, the lower end of the first coupling is connected with the telescopic shaft, the lower end of the telescopic shaft is connected with the connecting shaft 08, the lower end of the connecting shaft is co...

Embodiment 2

[0027] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 11 As shown, there are five pulse gas charging holes 075 on the lower end surface of the fixed shaft. The pulse gas inlet holes are distributed in a circular arc. The radius length of the air intake cavity is the same. One end of the sliding shaft inside the fixed shaft is provided with a piston that matches the diameter of the air chamber. When the gas volume in the air chamber increases, the piston can be pushed to move, thereby realizing the relative movement between the sliding shaft and the fixed shaft, and elongating the telescopic shaft; When the amount of gas in the air chamber decreases, it can attract the movement of the piston, and then shrink the telescopic shaft. The outer sleeve of the connecting shaft is provided with an air intake sleeve, which is connected with the connecting shaft through a rotating bearing. When the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com