A piston rod parts assembly system

A technology of parts assembly and piston rod, which is applied in the direction of workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of low assembly precision, high labor intensity, and low assembly efficiency, so as to improve assembly efficiency and reduce labor intensity , the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

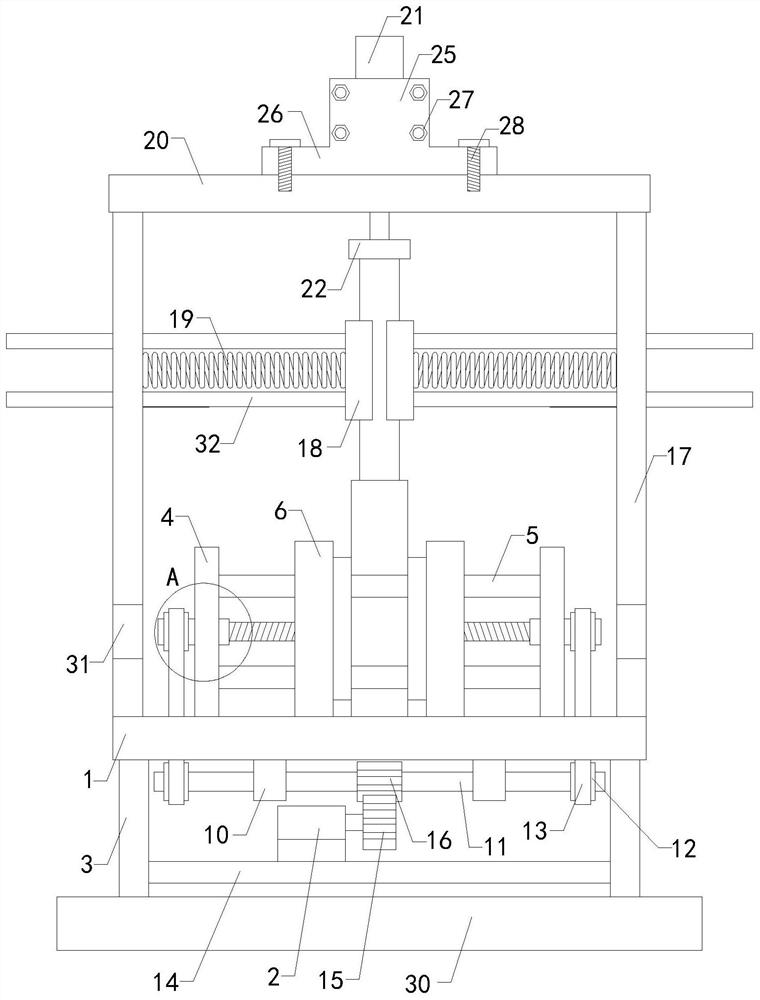

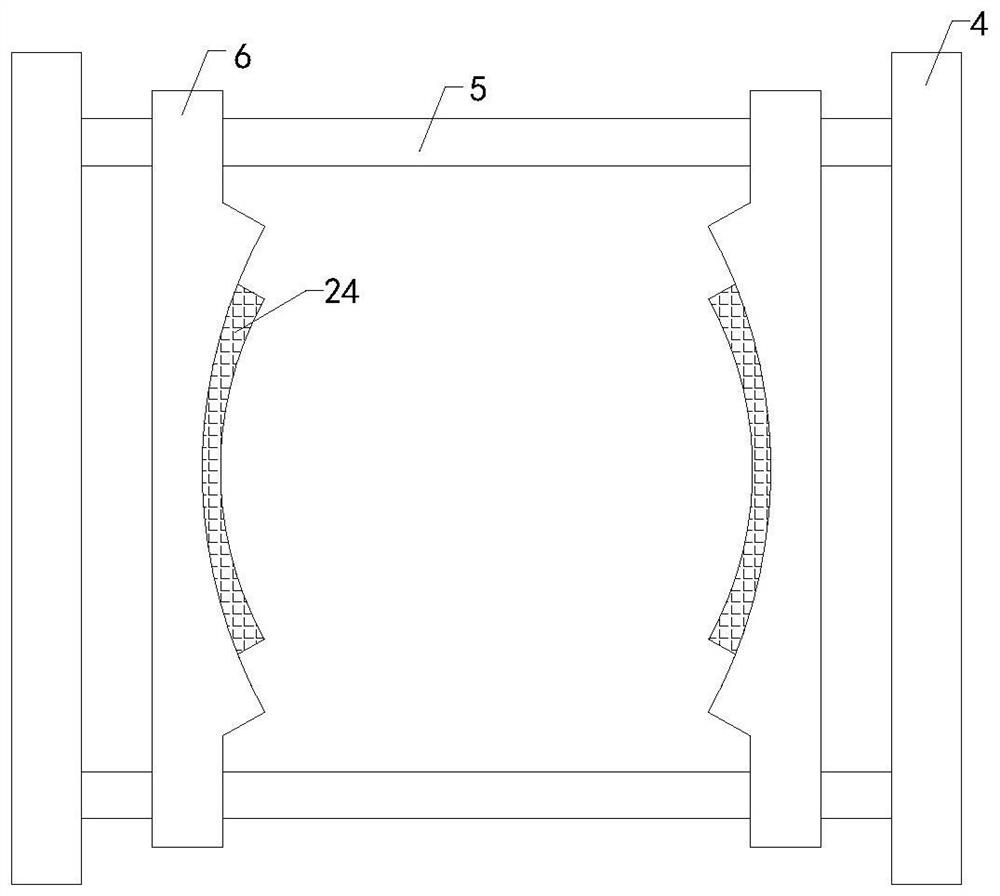

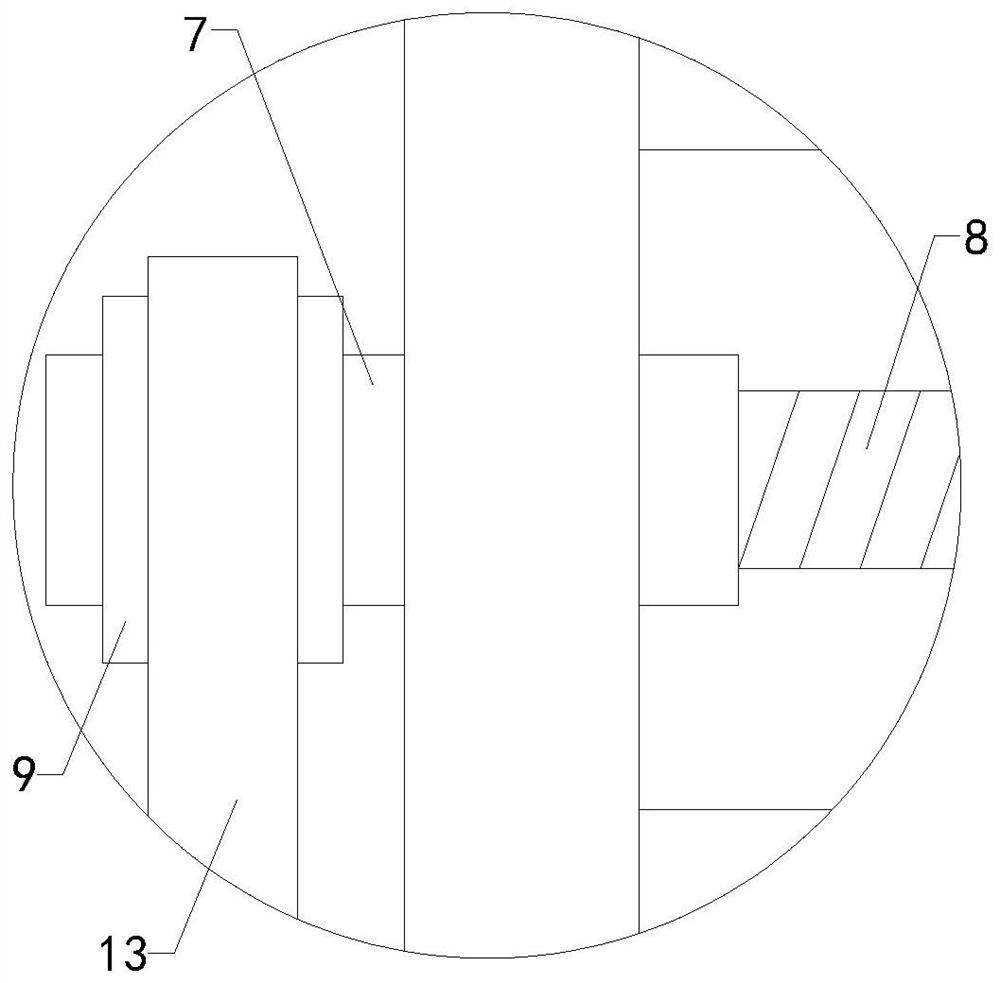

[0026] see Figure 1-5 , a piston rod parts assembly system, including a work plate 1 and a transmission motor 2, the left and right sides of the bottom end of the work plate 1 are longitudinally provided with support plates 3, and the left and right sides of the top end of the work plate 1 are provided with support plates 3. Symmetrically provided with a fixed plate 4, the front side and the rear side of the two fixed plates 4 are horizontally connected with a group of sliding columns 5, and two fixed splints 6 are symmetrically arranged on the two sets of sliding columns 5, and the two fixed splints 6 are There is a through hole suitable for the sliding column 5 to pass through, and the through hole is slidably matched with the sliding column 5 to ensure that the two fixed clamping plates 6 slide relative to each other laterally, which is convenient for the subsequent clamping adjustment of the cylinder body. The middle of the fixing plate 4 is provided with a fixed A thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com