Oil application device for machining water heating hardware

A hardware and plumbing technology, applied in the field of oiling devices for plumbing hardware processing, can solve problems such as poor oiling effect, and achieve the effect of improving oiling effect and avoiding jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

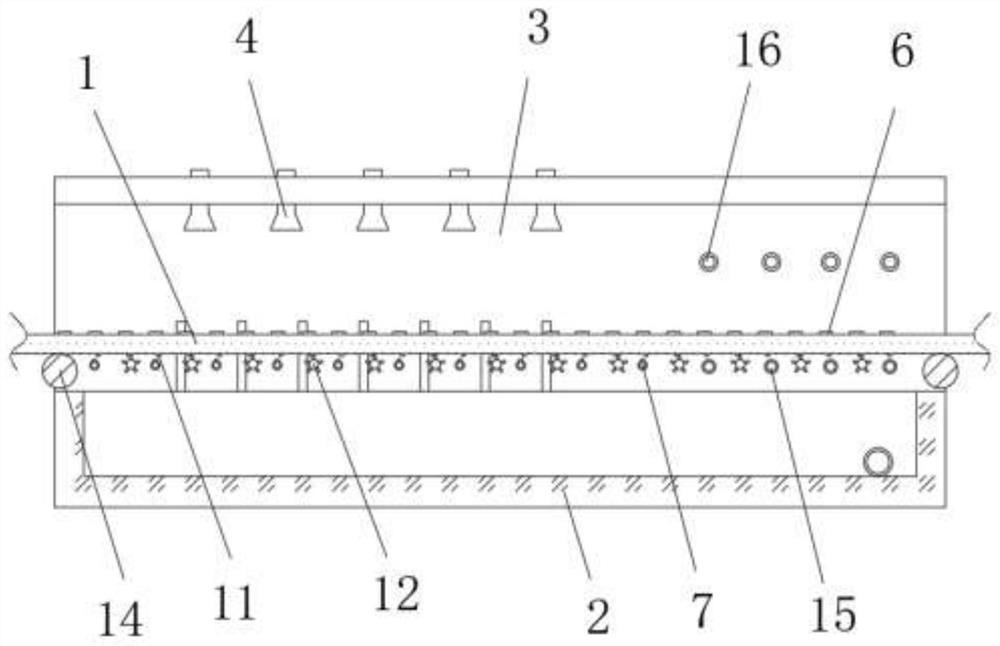

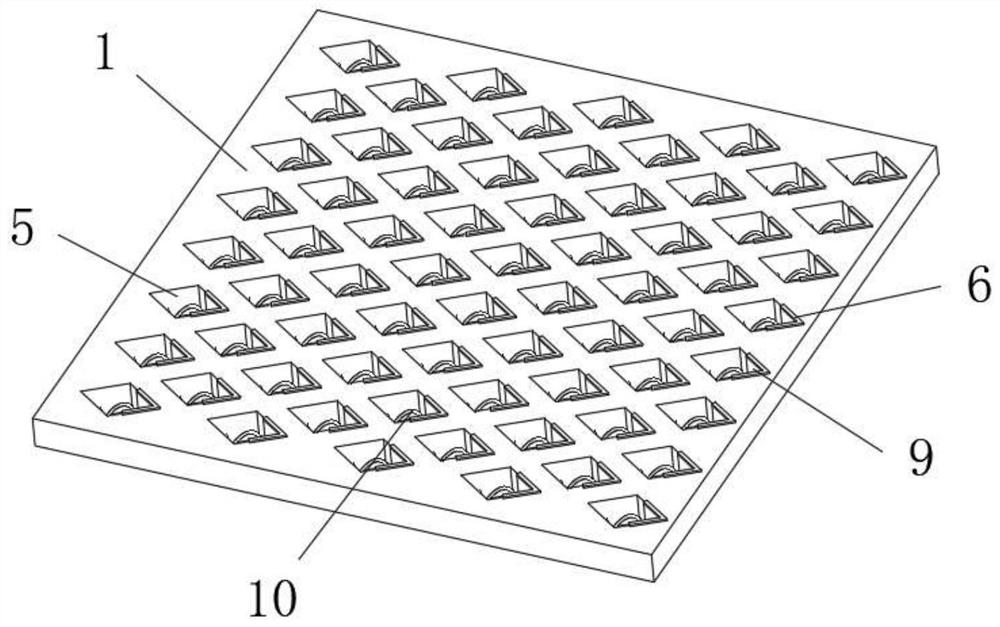

[0027] refer to Figure 1-4 , an oiling device for plumbing hardware processing, comprising a conveyor belt 1, a plurality of mesh holes 5 are provided on the top of the conveyor belt 1, a collection box 2 with an open top is provided at the bottom of the conveyor belt 1, and a collection box 2 on the top of the collection box 2 A fixed frame 3 is fixed between the two ends, and a plurality of nozzles 4 are fixed on the top of the fixed frame 3. The mesh 5 is arranged in a diamond-shaped structure, and the four water chestnuts of the mesh 5 are respectively arranged in the moving direction of the conveyor belt 1 and are perpendicular to each other. The two sides of the conveyor belt 1 are respectively set as the feed end and the discharge end, and the top of the conveyor belt 1 is located on the side of the mesh 5 near the discharge end, and a V-shaped spacer 6 is fixed on the side. The edge of the position corresponding to the hole 5 is suitable.

[0028] In the present inve...

Embodiment 2

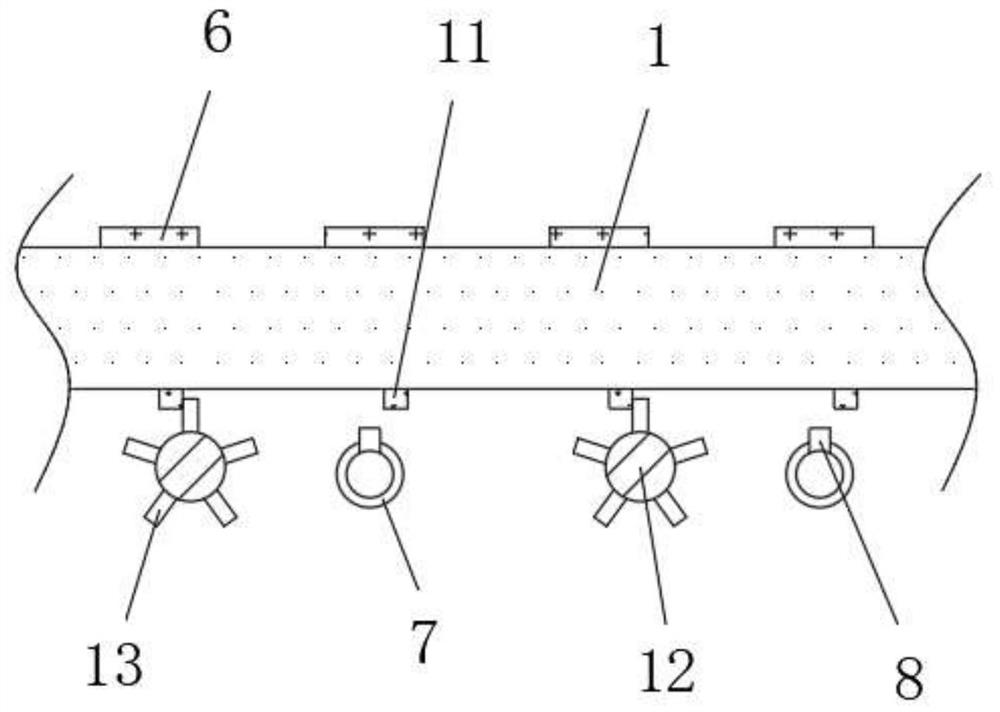

[0034] refer to Figure 1-5, an oiling device for plumbing hardware processing, the rotating part 12 is arranged as a tubular structure with one end open, and the middle position of the toggle part 13 is provided with an air chamber 13 communicating with the rotating part 12, the top of the air chamber 13 and The bottom end is penetratingly arranged, and the position corresponding to the opening of the rotating part 12 at one end of the fixing frame 3 is fixed with a positioning tube 17, and the outer wall of the positioning tube 17 is rotationally connected with the inner wall of the rotating part 12. For the air blower, the inner wall of the air chamber 18 away from the rotating part 12 is arranged in a conical structure that shrinks outwards, and the outer wall of the peripheral end of the toggle part 13 away from the rotating part 12 is arranged in an arc-shaped structure.

[0035] When in use, swing upward from the air cavity 18 to blow air, and the air flow passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com