Patents

Literature

84results about How to "Guaranteed overlap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

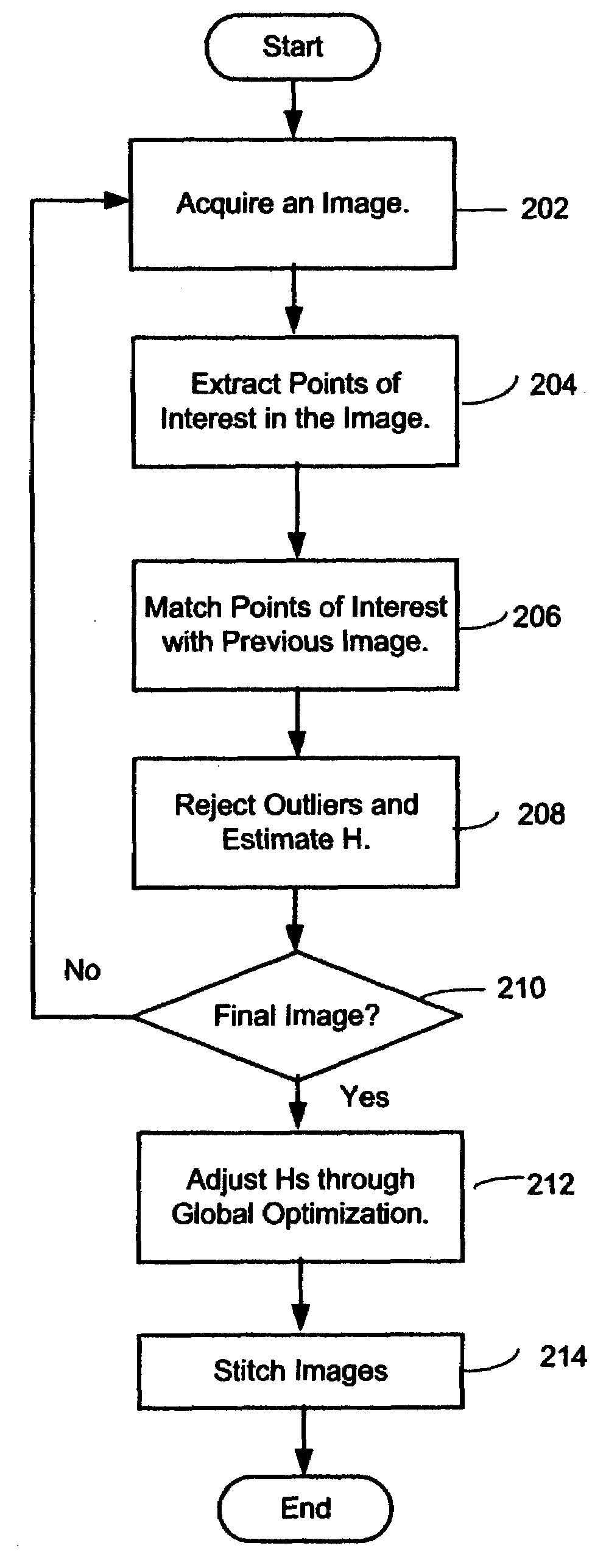

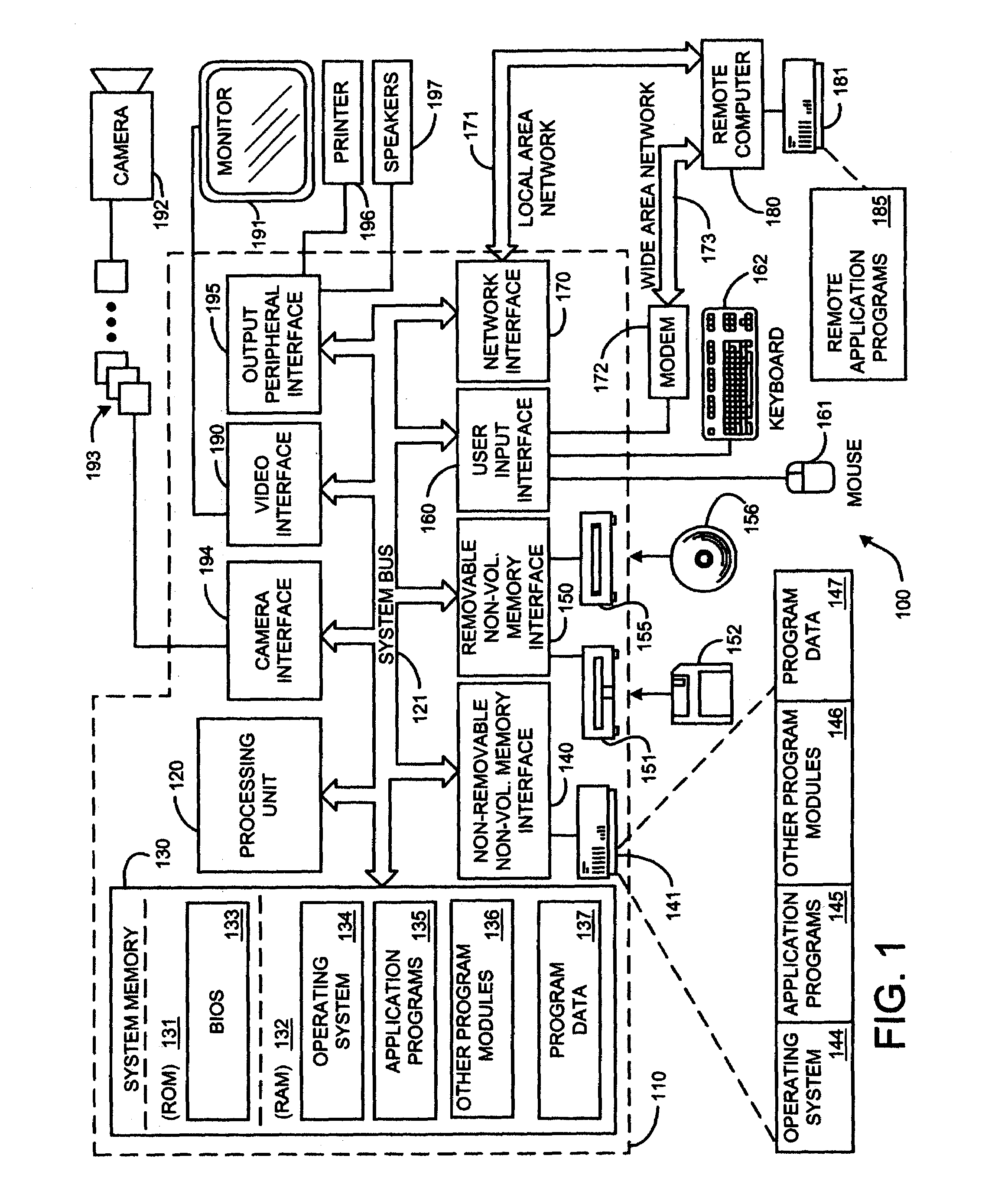

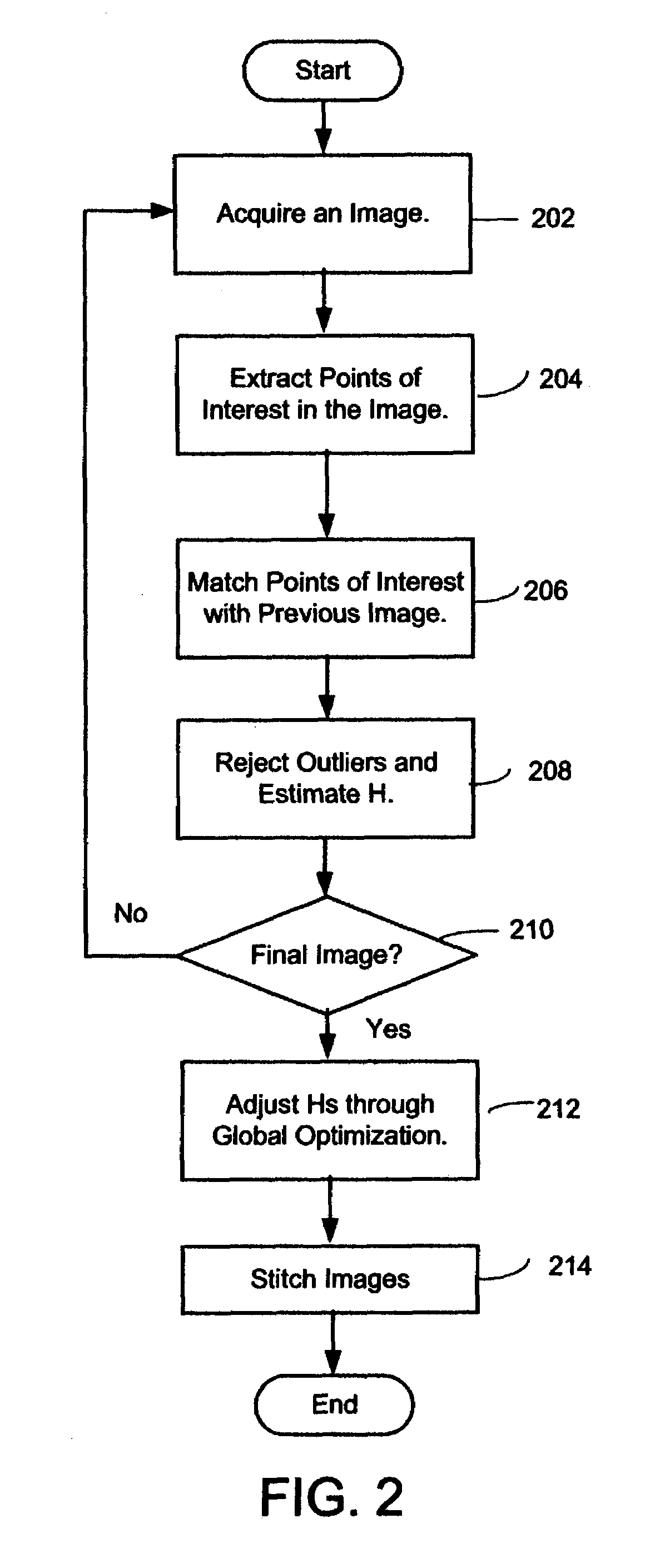

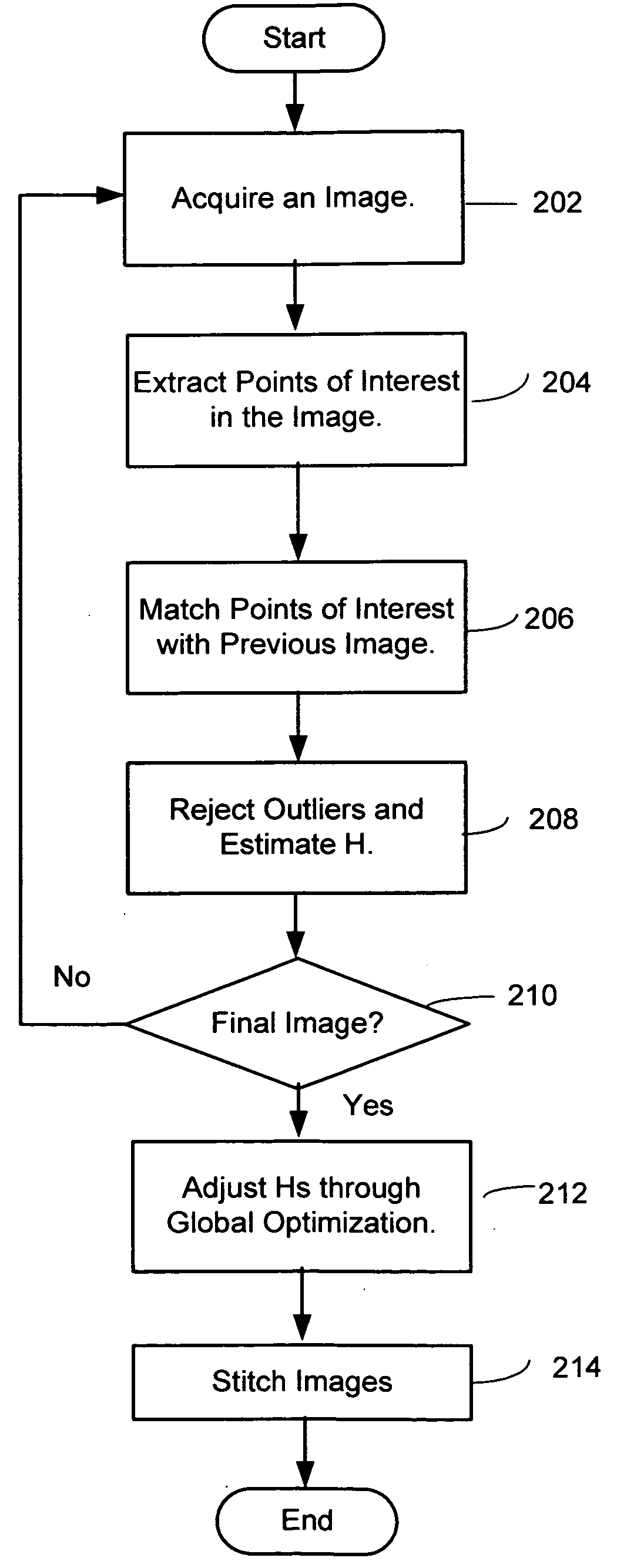

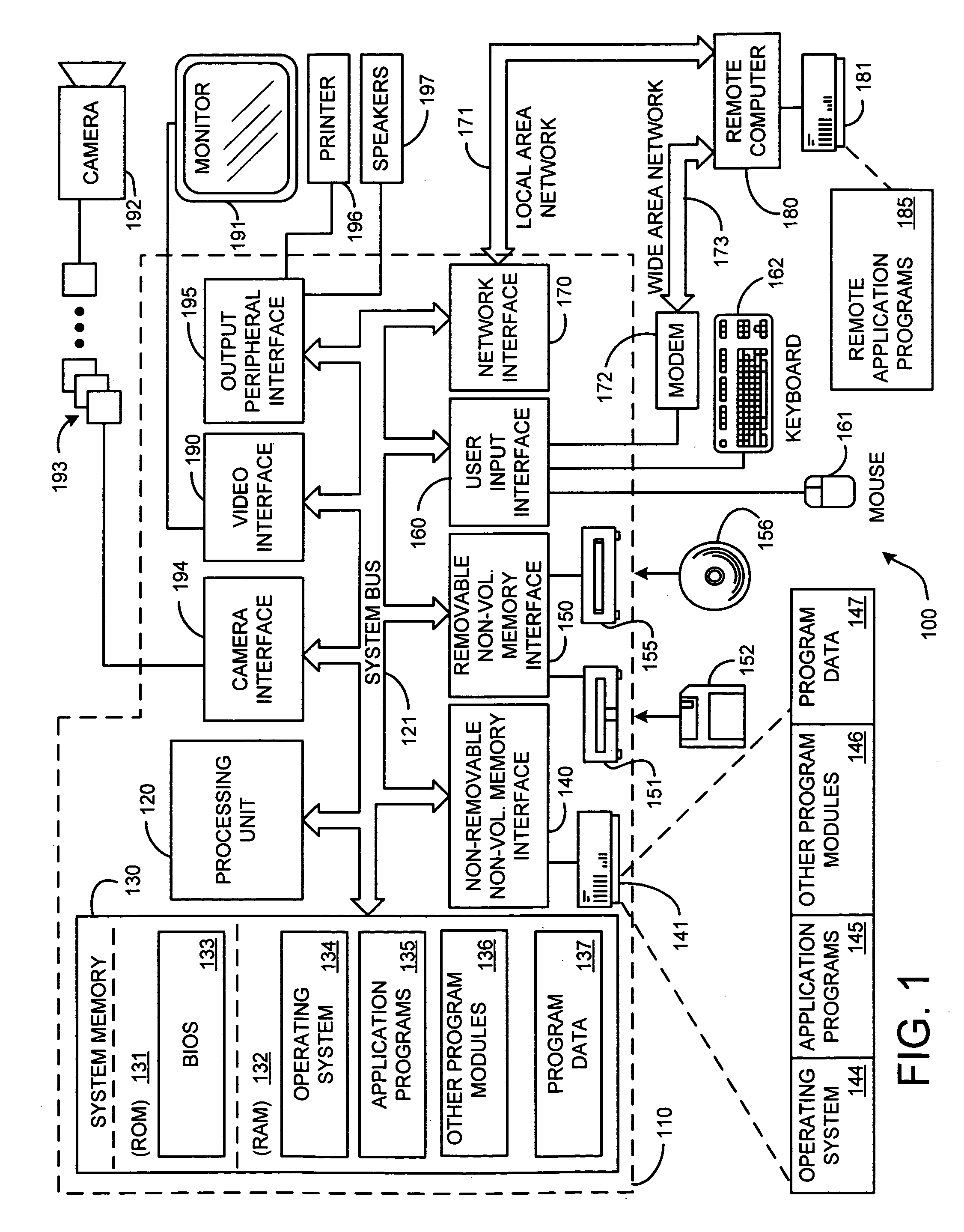

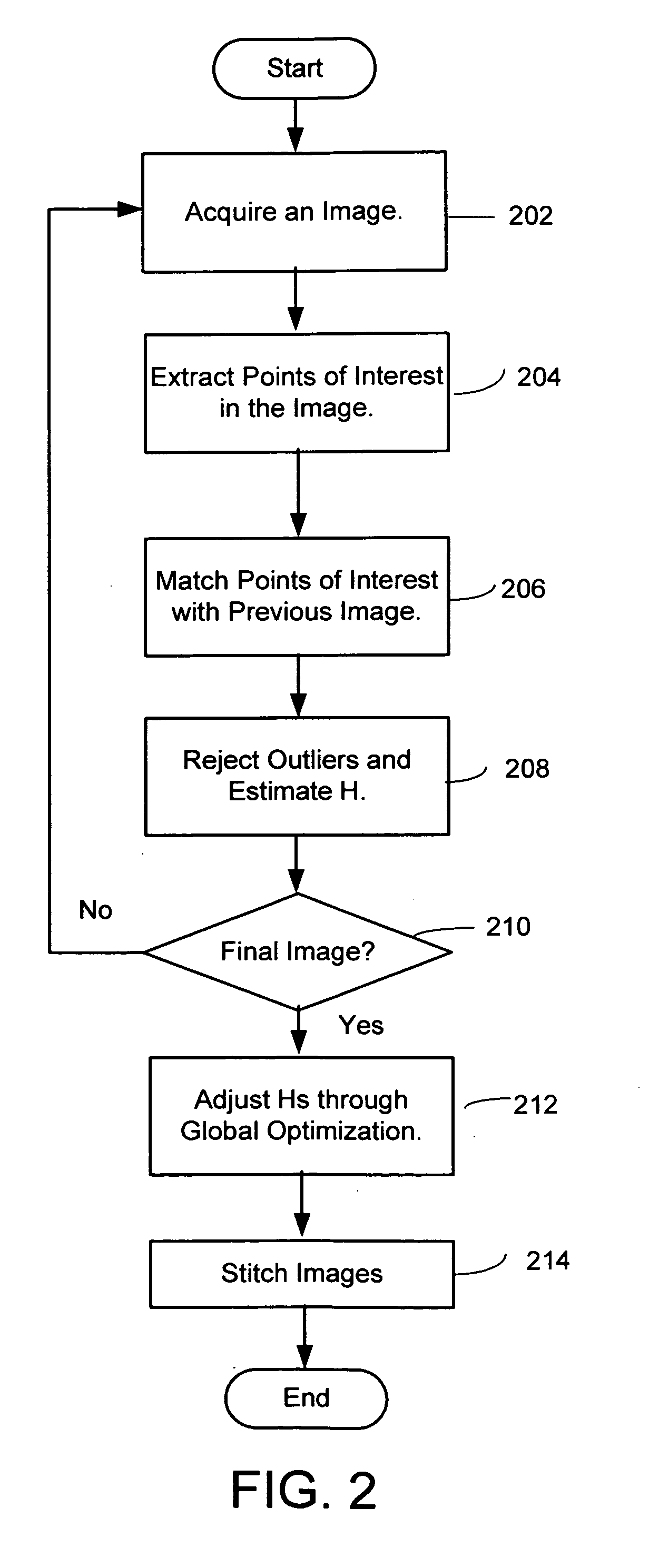

System and method for whiteboard scanning to obtain a high resolution image

InactiveUS7119816B2Reduce blurGuaranteed overlapTelevision system detailsSolid-state devicesWhiteboardImaging processing

This invention is directed toward a system and method for scanning a scene or object such as a whiteboard, paper document or similar item. More specifically, the invention is directed toward a system and method for obtaining a high-resolution image of a whiteboard or other object with a low-resolution camera. The system and method of the invention captures either a set of snapshots with overlap or a continuous video sequence, and then stitches them automatically into a single high-resolution image. The stitched image can finally be exported to other image processing systems and methods for further enhancement.

Owner:MICROSOFT TECH LICENSING LLC

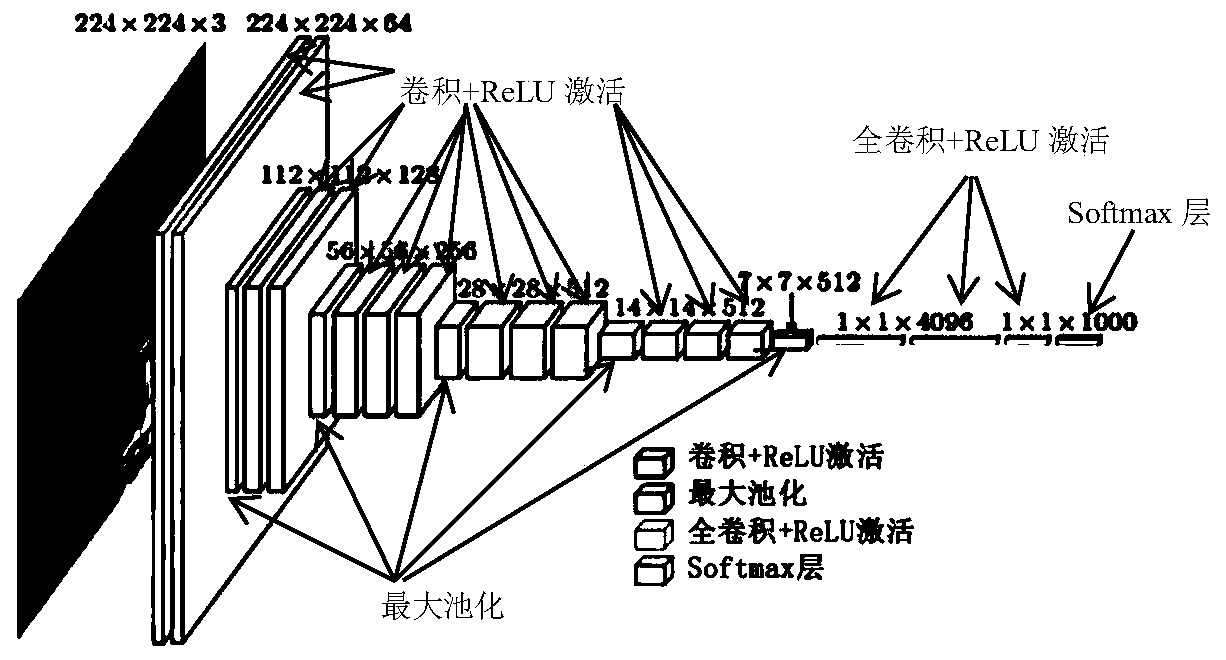

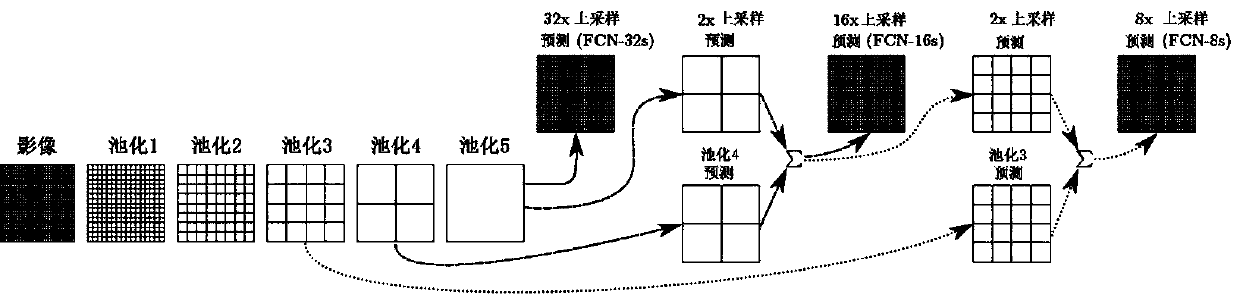

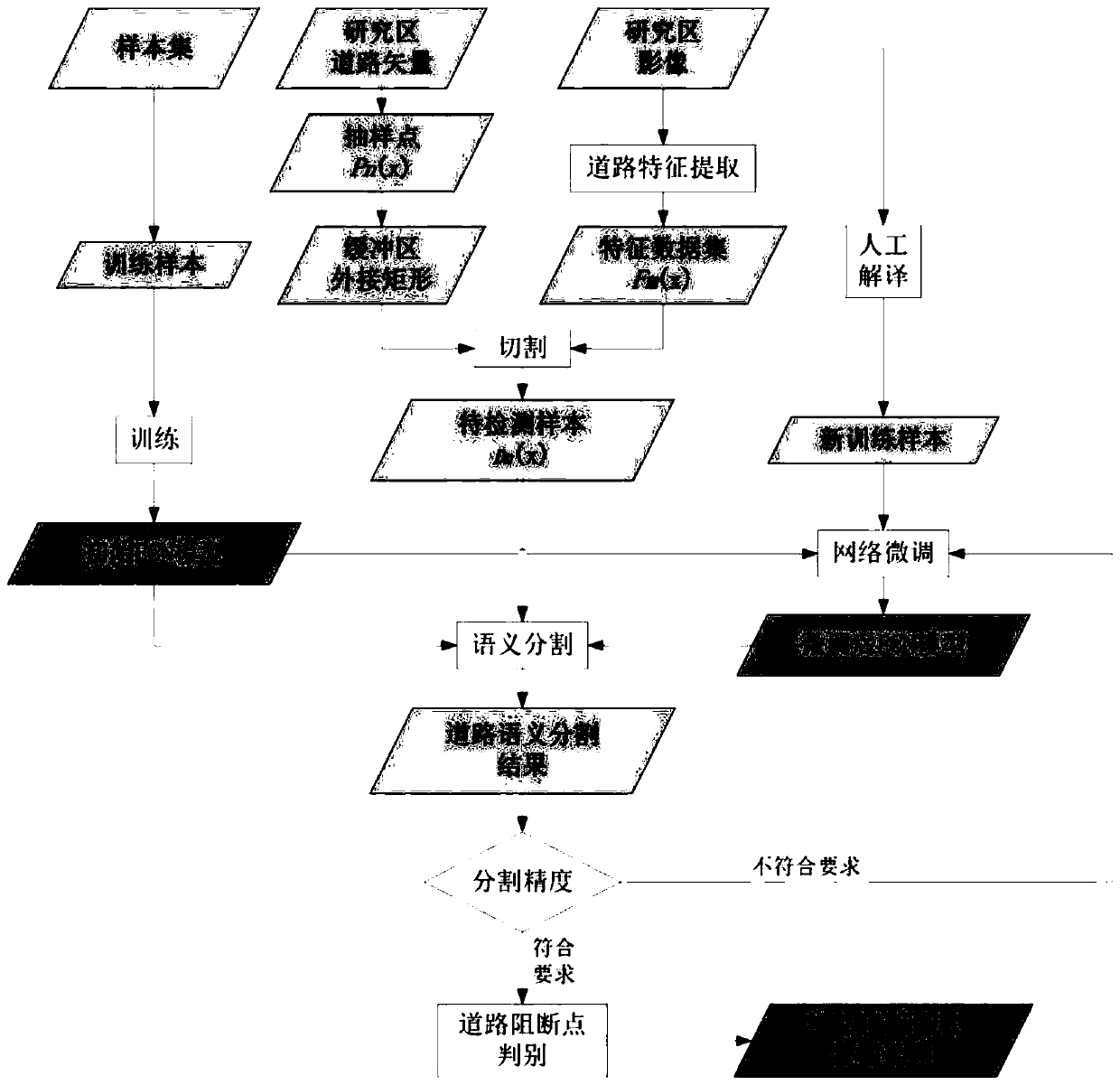

Road blocking information extraction based on deep learning image semantic segmentation

ActiveCN110287932AReduce misjudgmentGuaranteed correspondenceImage enhancementImage analysisPost disasterAlgorithm

The invention discloses a construction method of a road blocking image semantic segmentation sample library for full convolutional neural network training. The construction method comprises the steps of performing vectorization, enhancement and standardization on samples; secondly, introducing a classical convolutional neural network type and a network structure improvement method, and explaining a network realization method and a training process; then, using the full convolutional neural network obtained through training for conducting remote sensing image road surface semantic segmentation, and on the basis that the road surface which is not damaged after disaster is extracted, judging the road integrity through the length proportion of the road which is not damaged before disaster and after disaster. The precision evaluation indexes of the improved full convolutional neural network model are superior to those of an original full convolutional neural network model. The improved model is more suitable for specific problems of post-disaster undamaged pavement detection and road integrity judgment, and the adverse effects of tree and shadow shielding on road blocking information extraction can be effectively overcome.

Owner:AEROSPACE INFORMATION RES INST CAS

System and method for whiteboard scanning to obtain a high resolution image

InactiveUS20050104902A1Reduce blurGuaranteed overlapTelevision system detailsSolid-state devicesWhiteboardImaging processing

This invention is directed toward a system and method for scanning a scene or object such as a whiteboard, paper document or similar item. More specifically, the invention is directed toward a system and method for obtaining a high-resolution image of a whiteboard or other object with a low-resolution camera. The system and method of the invention captures either a set of snapshots with overlap or a continuous video sequence, and then stitches them automatically into a single high-resolution image. The stitched image can finally be exported to other image processing systems and methods for further enhancement.

Owner:MICROSOFT TECH LICENSING LLC

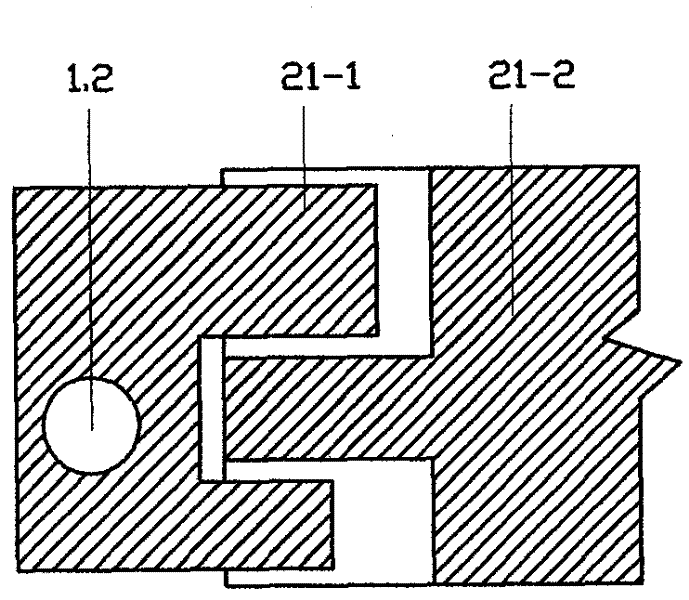

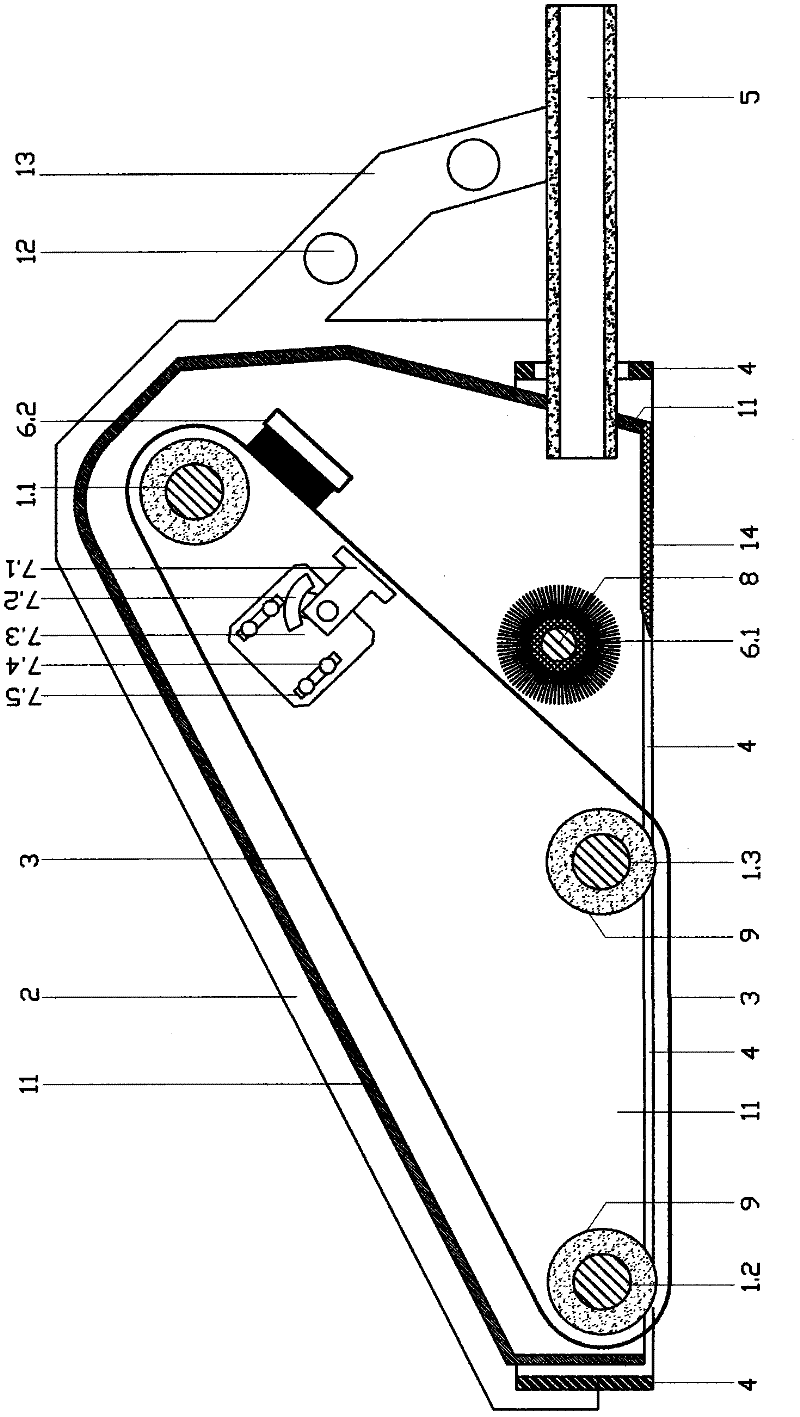

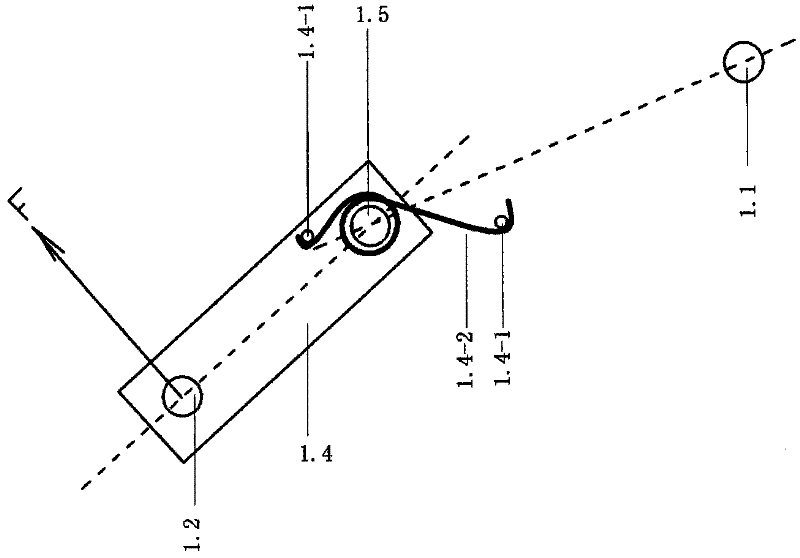

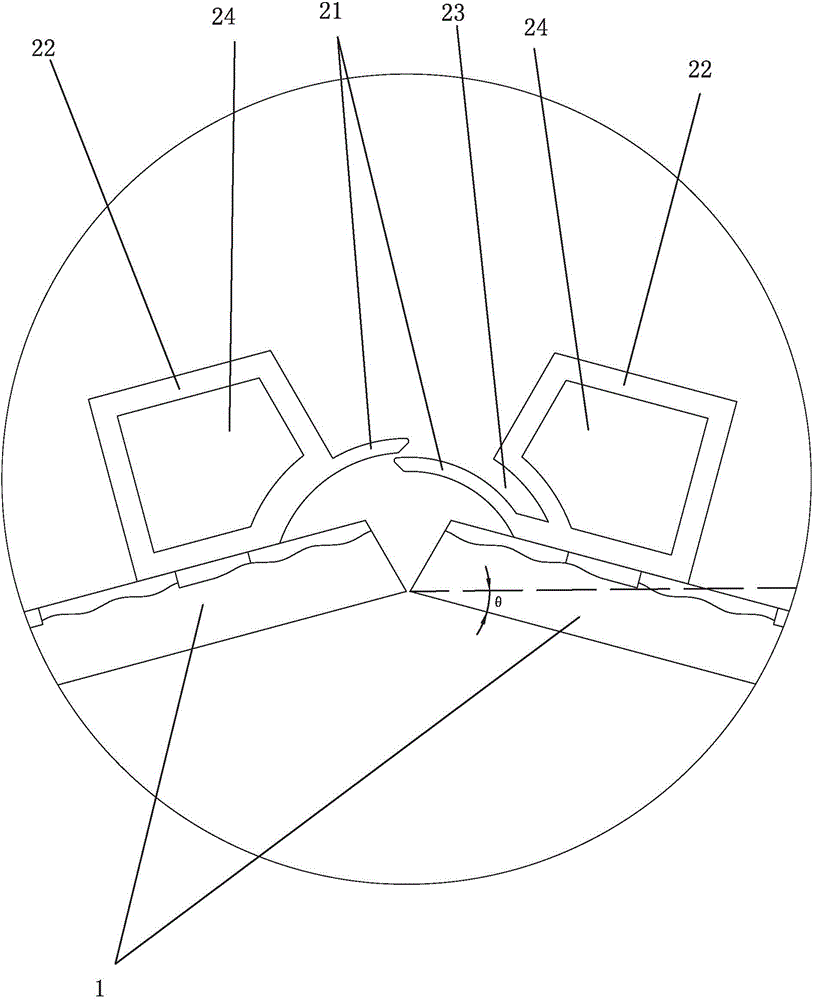

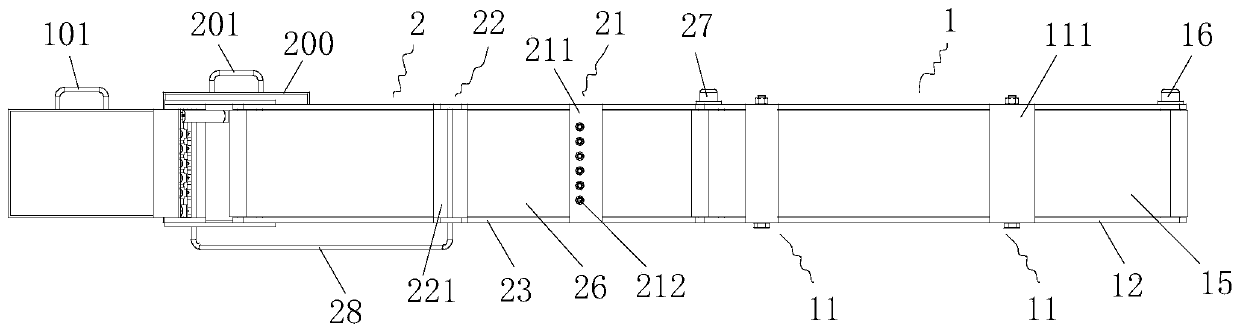

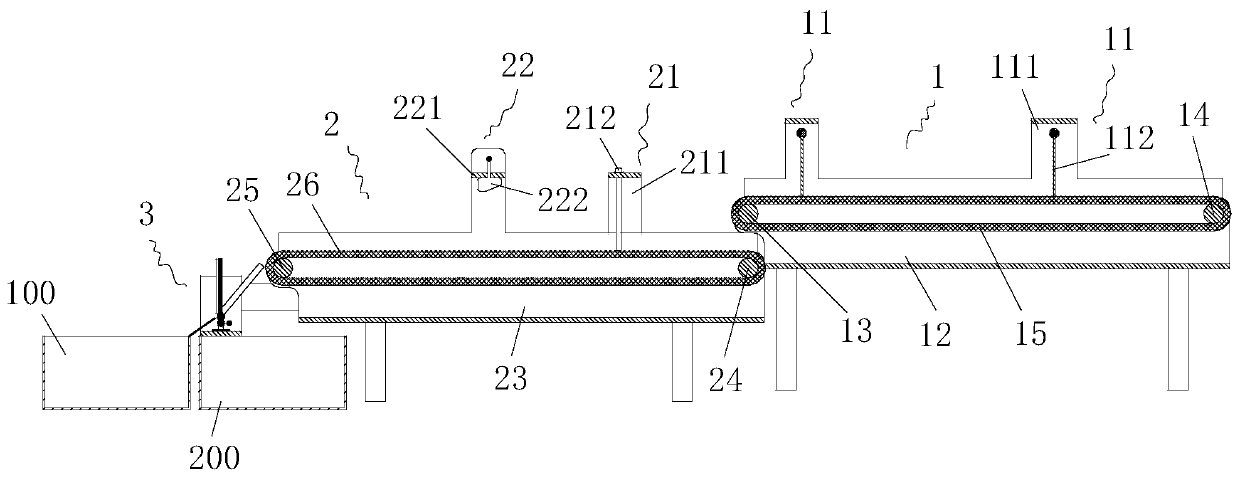

Belt type grinding machine head

InactiveCN102335876AGuaranteed overlapGuaranteed share functionBelt grinding machinesGrinding/polishing safety devicesDust controlBrush device

The invention relates to a belt type grinding machine head comprising a headstock, a power device, an abrasive belt system, a dust hood, a balancing stand, a vibrating mechanism, a brush device and the like; and after being connected with dust collecting equipment and the like, the belt type grinding machine head can form entire grinding and dust removal functions. The headstock is a formwork of the grinding machine head and the assembly of all the mechanisms; a driving abrasive belt shaft drives an abrasive belt to circularly run, a driven abrasive belt shaft and an auxiliary abrasive belt shaft passively rotate, and the abrasive belt is supported together to form a spacial three-dimensional shape, i.e., a grinding surface; the driving abrasive belt shaft is fixedly installed on the headstock, and the driven abrasive belt shaft can move relative to the driving abrasive belt shaft to adjust the abrasive belt so that the abrasive belt tightens or loosens; the abrasive belt is cleaned by using a brush and the vibrating mechanism, the dust hood, the balancing stand and a ground surface form a sealed space for packing and collecting dust; and dust is sucked from the dust hood by the dust collecting equipment and then treated and discharged by professional dust collecting equipment.

Owner:孙长顺

Fluorescent genotyping detection kit and detection method for eight K-ras gene mutations

InactiveCN103695555AReduce the number of reaction tubesFew samplesMicrobiological testing/measurementK-ras GenesFluorescence

The invention belongs to the field of biotechnology and clinical molecular diagnosis and in particular relates to a fluorescent genotyping detection kit and a detection method for eight human K-ras gene mutations. According to the method, an MGB (minor groove binder) probe technology is combined with a mismatch ARMS (amplification refractory mutation system) technology, an MGB probe complementary with a DNA (deoxyribonucleic acid) plus strand and an ARMS downstream primer complementary with a DNA minus strand are designed at allelic gene loci, a mismatch locus is introduced in the ARMS downstream primer, the MGB probe is overlapped with the ARMS primer by not more than 5 bp, and the eight human K-ras gene mutations are subjected to genotyping detection by four reaction pipes based on multiple fluorescent PCR (polymerase chain reaction). The method has the advantages of good specificity, high sensitivity, simplicity and quickness for operation, accuracy for genotyping, simplicity for result interpretation and the like, and can be used for detecting the clinical K-ras gene mutations and helping doctors screen the crowed with effective anti-EGFR (epidermal growth factor receptor) treatment.

Owner:SHANGHAI XINGYAO MED TECH DEV CO LTD +1

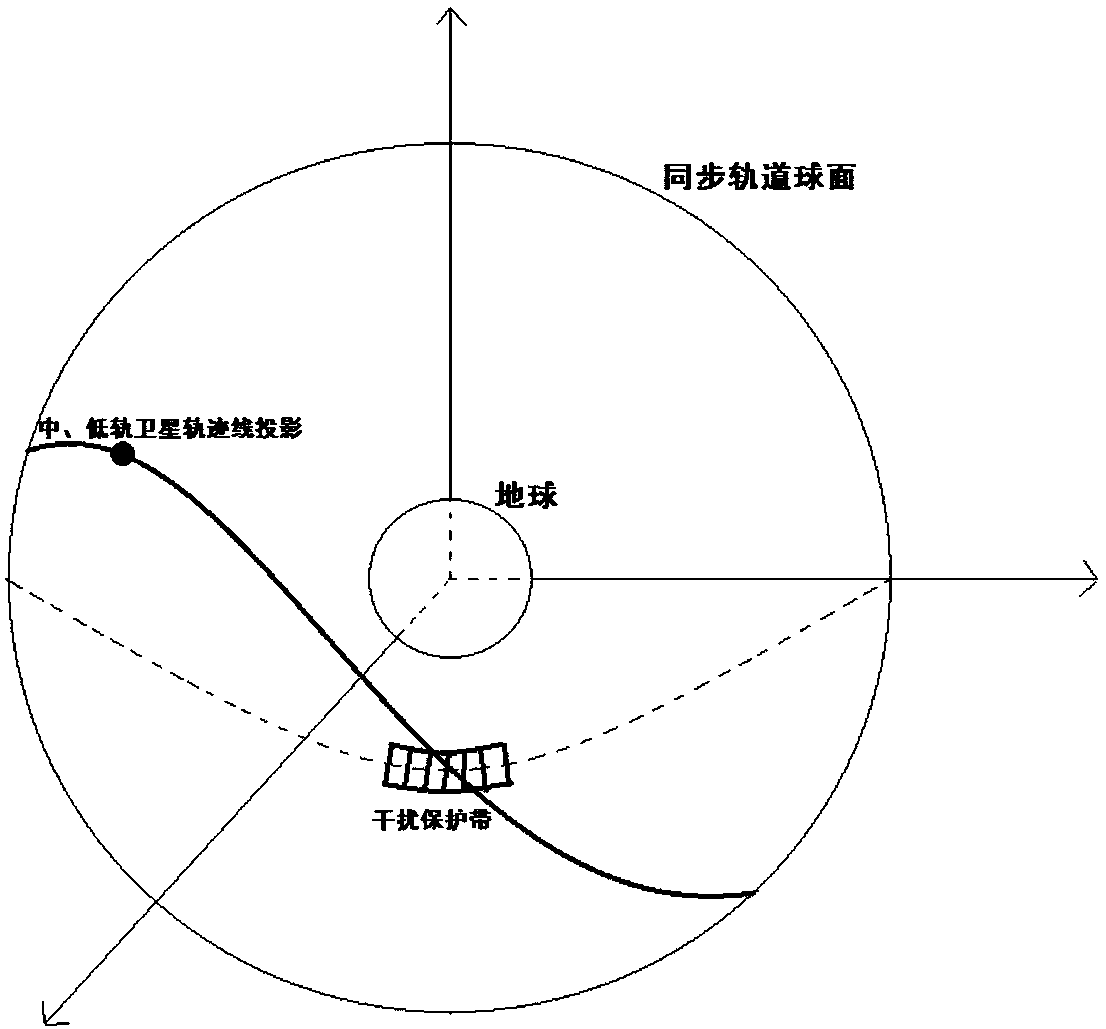

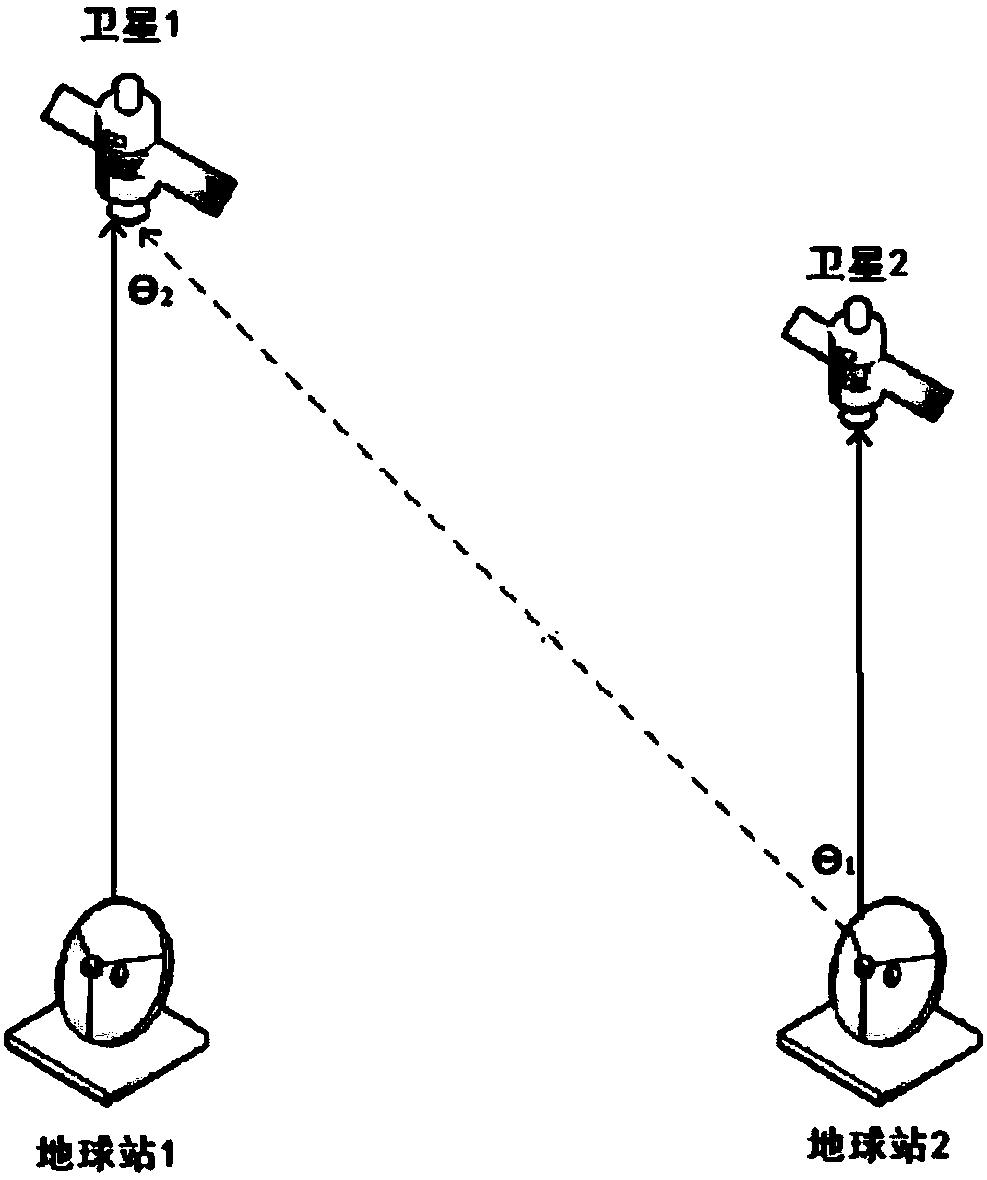

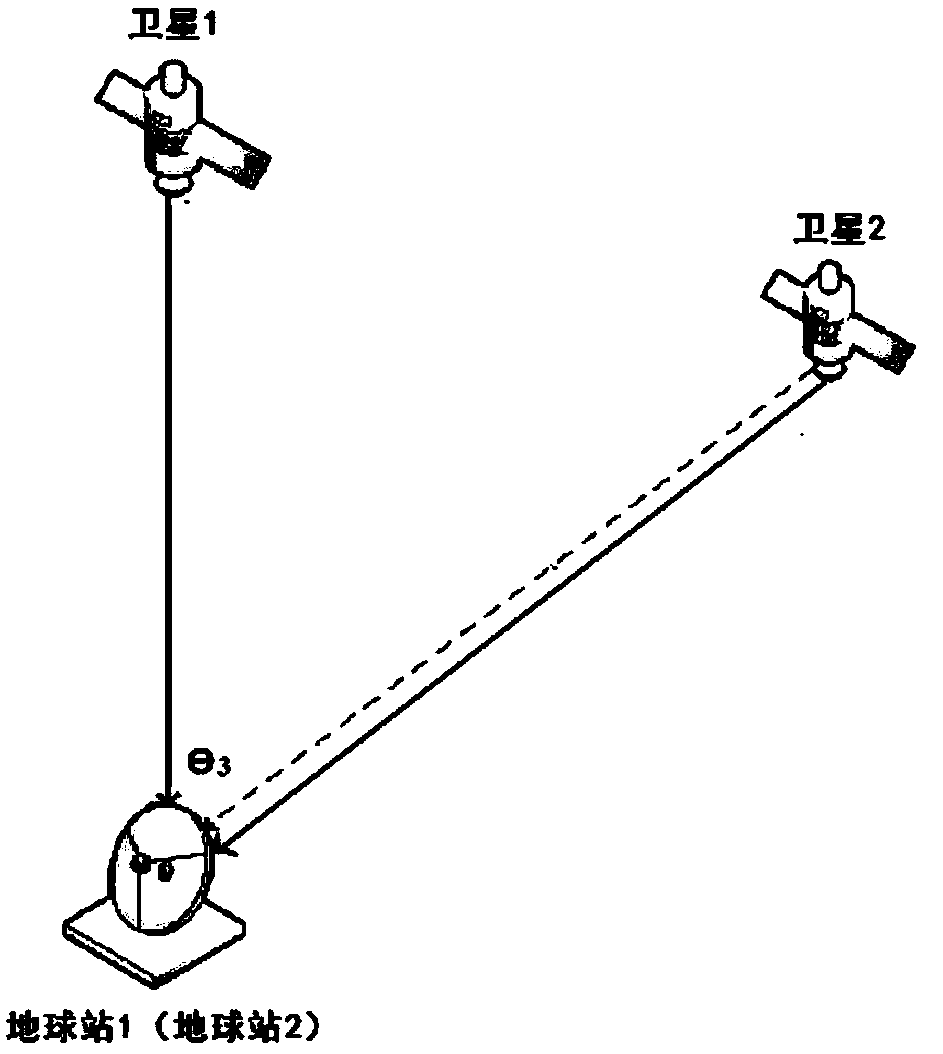

Method for performing interference analysis and avoidance on synchronous orbit satellite communication system

ActiveCN107809298AReduce the amount of online dataReduce the impact of communication qualityNetwork topologiesActive radio relay systemsCommunications systemSynchronous orbit

The invention relates to a method for performing interference analysis and avoidance on a synchronous orbit satellite communication system, characterized by including the following steps: 1) designinga recursive orbit for medium-earth and low-earth orbit satellites in a non-synchronous orbit satellite communication system to ensure that tracks of sub-satellite points of each satellite are periodically overlapped and cross over the equator at a plurality of fixed longitude points; 2) determining a range of the synchronous orbit satellite communication system that needs to perform interferenceanalysis according to relevant protection standards of the International Telecommunication Union; 3) performing interference analysis on the synchronous orbit satellite communication system, and setting corresponding interference protection belt zones for synchronous orbit satellites; and 4) enabling an earth station of the non-synchronous orbit satellite communication system to determine whetherthe medium-earth and low-earth orbit satellites need to take avoidance measures according to predicted system parameters and the running states of each medium-earth and low-earth orbit. The method disclosed by the invention can be widely applied in the field of interference analysis and avoidance of the synchronous orbit satellite communication system.

Owner:TSINGHUA UNIV

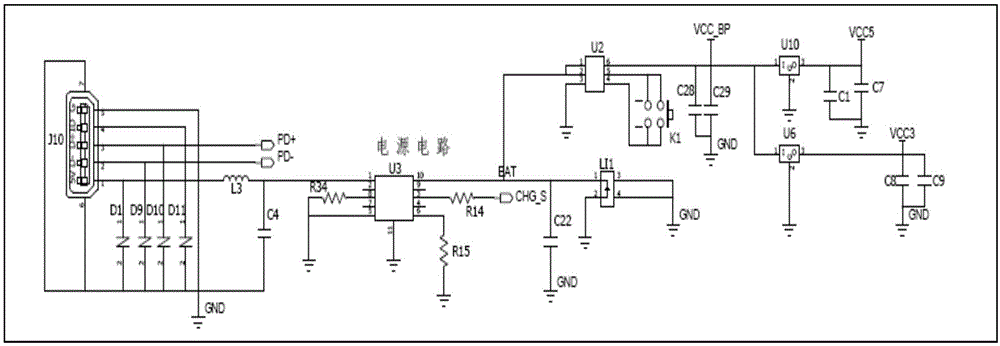

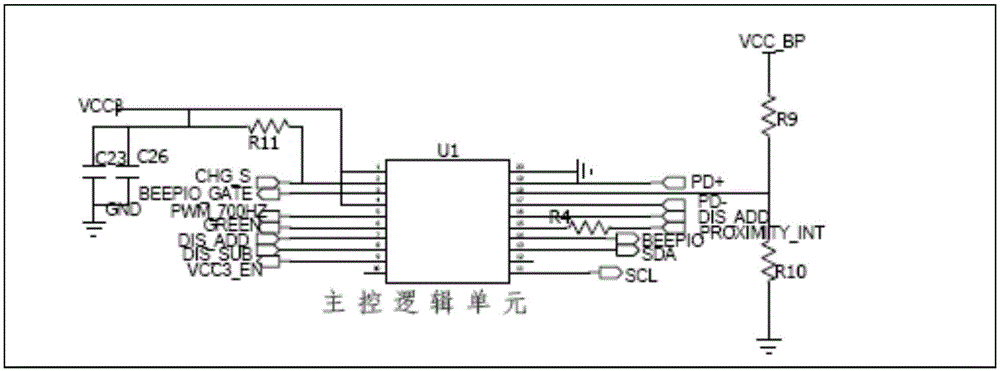

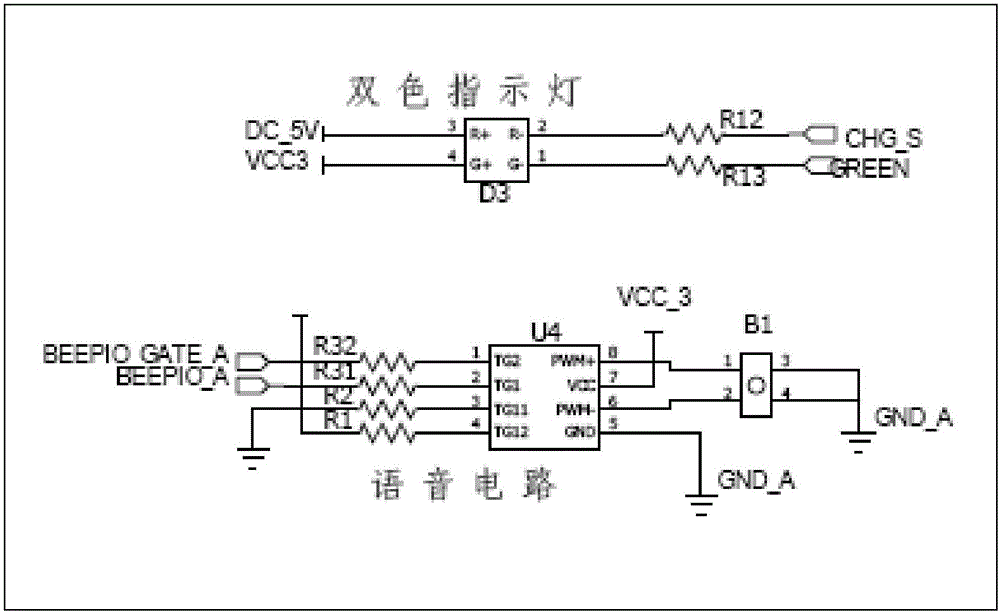

Glasses frame type intelligent eyesight protection instrument

The invention discloses a glasses frame type intelligent eyesight protection instrument comprising a sensor, a controller, and an alarm device. The sensor is used to measure the distance and the angle of tilt, wherein the distance is measured by a triangulation distance measuring method based on a PSD and a CCD, an energy method, or a TOF method, and the angle of tilt is measured by a gravity accelerometer sensor or gyroscope. The controller receives corresponding data measured by the sensor, compares the data with a set value according to the measurement result, and triggers the alarm device to send an alarm if the data exceeds a set range. The alarming device alarms according to a control command of the controller. The glasses frame type intelligent eyesight protection instrument uploads alarm information to a cloud or terminal. The glasses frame type intelligent eyesight protection instrument has the advantage that by monitoring the learning posture of users and making cloud analysis of the learning posture, users are helped to develop a fine learning posture, the parents of the users are timely notified to take measures when the eyesight of the users decreases, and the eyesight is protected effectively.

Owner:南京智松电子科技有限公司

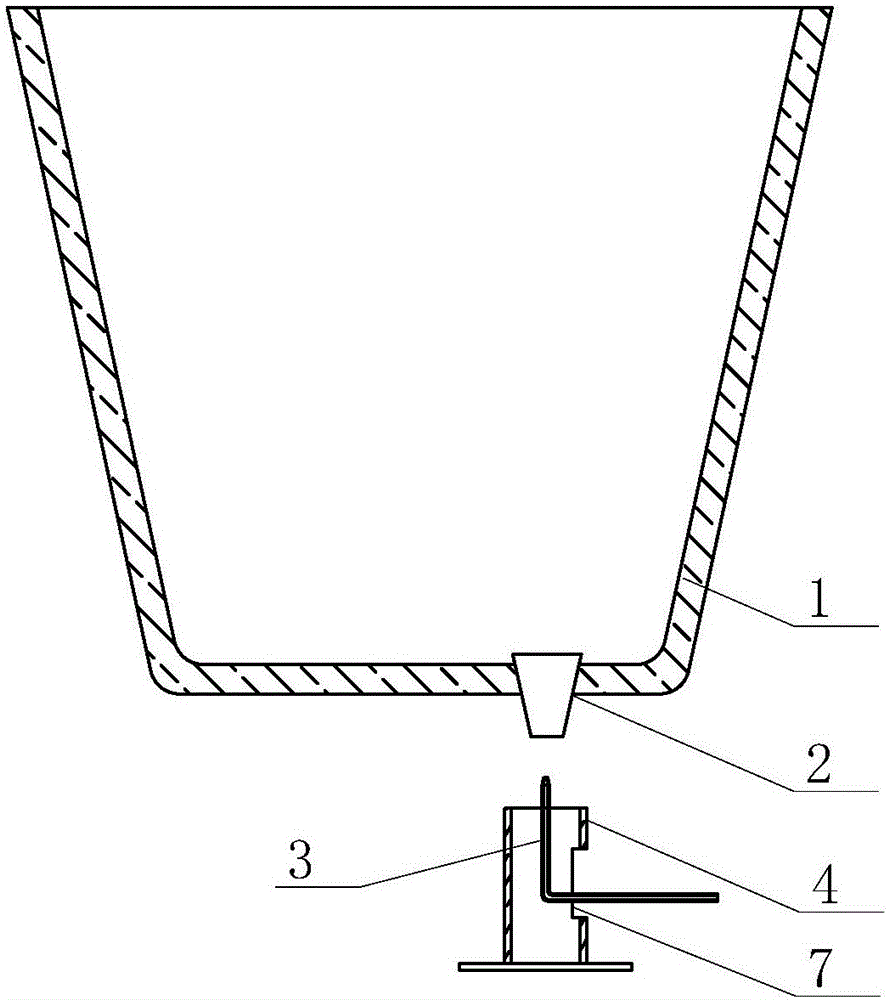

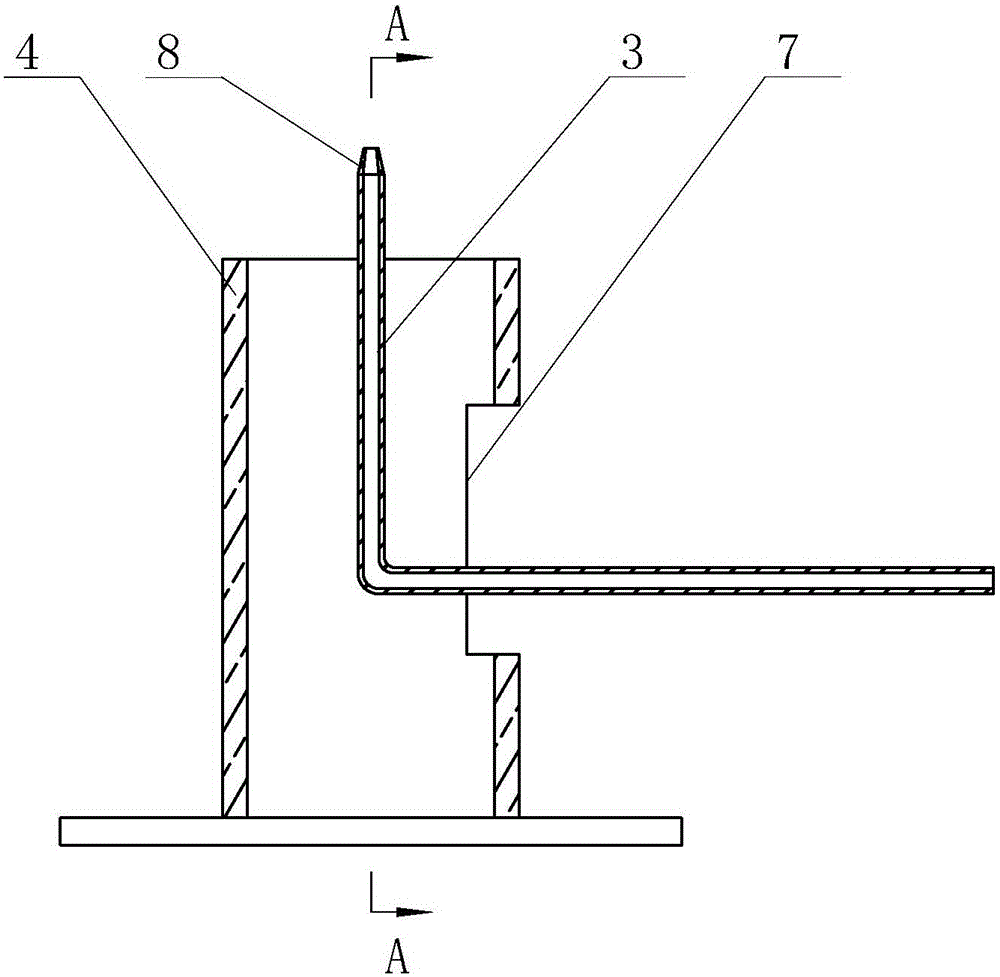

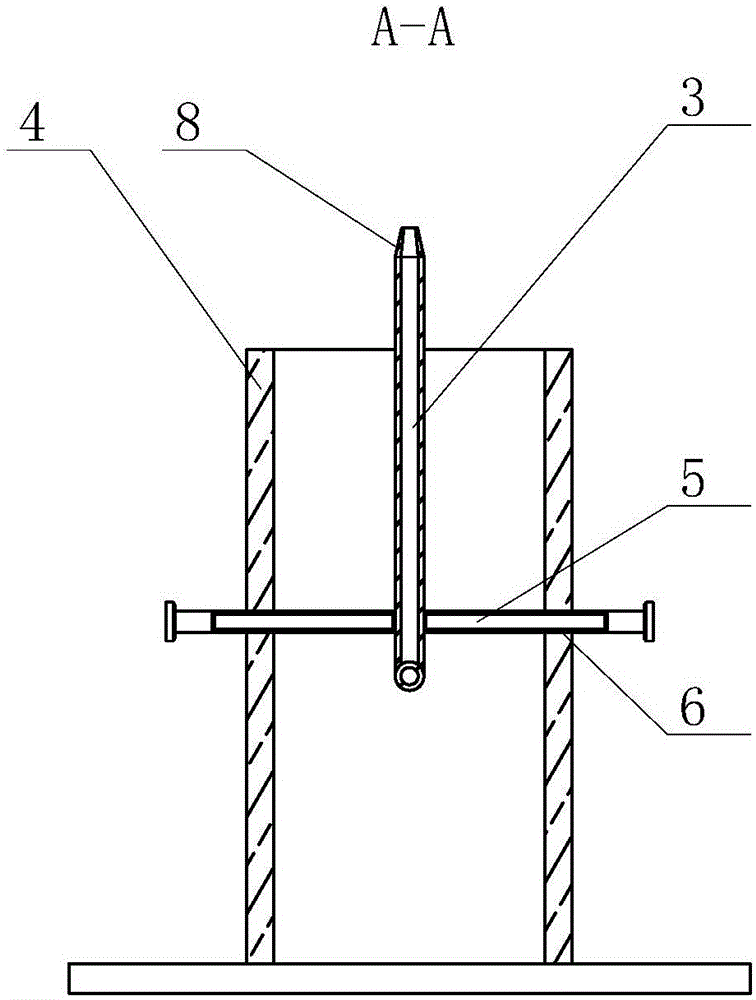

Automatic cooling and lubricating device for forging die

ActiveCN106825357ARealize automatic controlFull sprayForging/hammering/pressing machinesSpray nozzleEngineering

The invention discloses an automatic cooling and lubricating device for a forging die, and belongs to the technical field of metal press working. The device comprises a spray nozzle, a pushing device and a fixing device. The spray nozzle is arranged on the fixing device, and extends to a die. The pushing device is used for pushing the fixing device to do retracting motion. When the an upper die and a lower die of the die are made, the pushing device pushes the fixing device to extend to the direction approaching the die. The spray nozzle protrudes into the space between an upper die cavity and a lower die cavity for cooling and lubricating. When the upper die and the lower die are combined, the pushing device pushes the fixing device to extend to the direction away from the die, and the spray nozzle backs out of the upper die and the lower die. The automatic cooling and lubricating device for the forging die overcomes the shortcomings that in the prior art, the automation level and work efficiency of the cooling and lubricating of the forging die are low, the work efficiency is effectively increased and the temperature is effectively reduced. The structure is simple, the use is convenient, and the temperature reduction is uniform.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

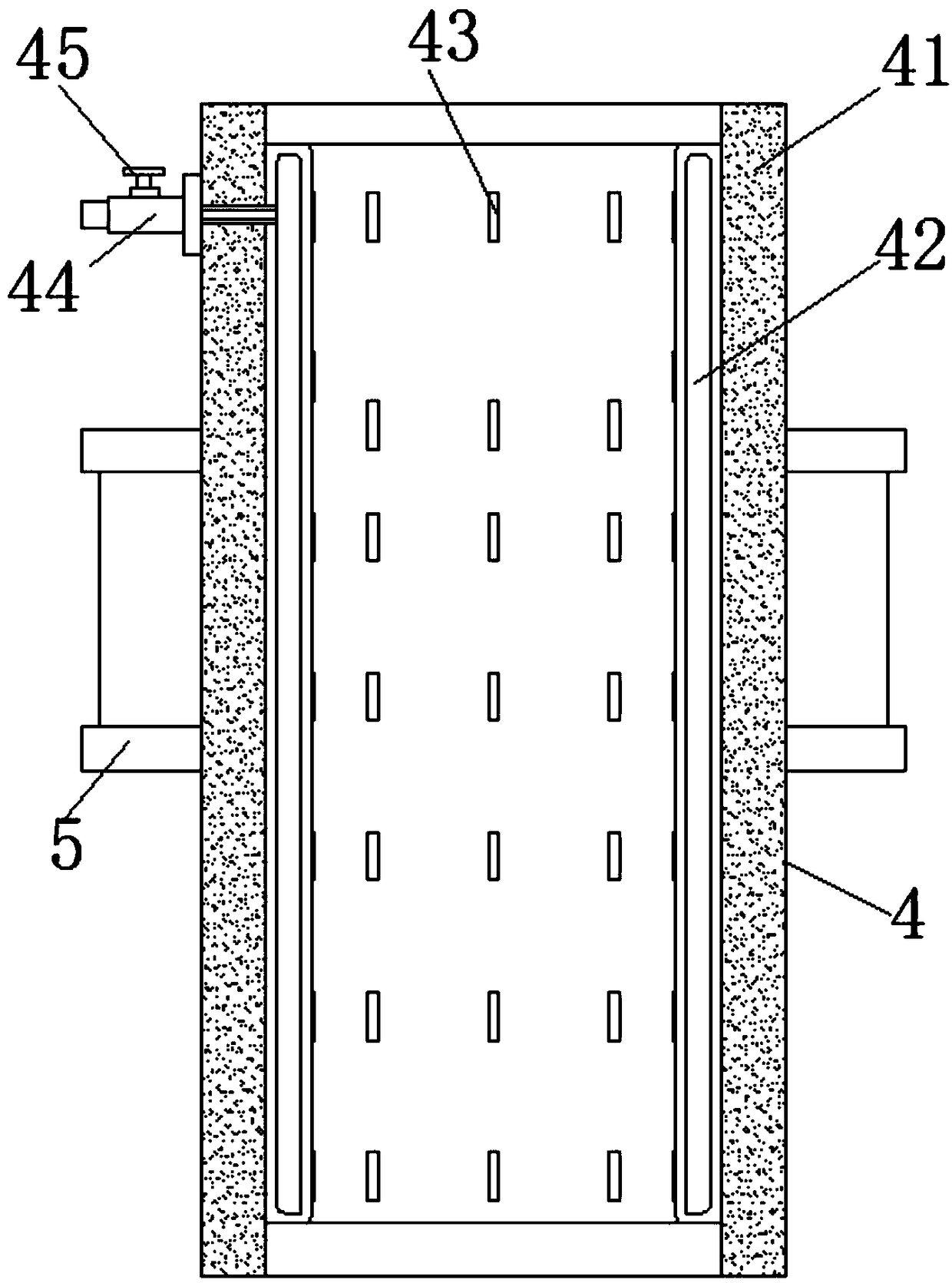

Tailing solid waste resource recycling and reusing treatment device

ActiveCN110064593ASave waterWill not polluteSievingGas current separationResource recoveryWater resources

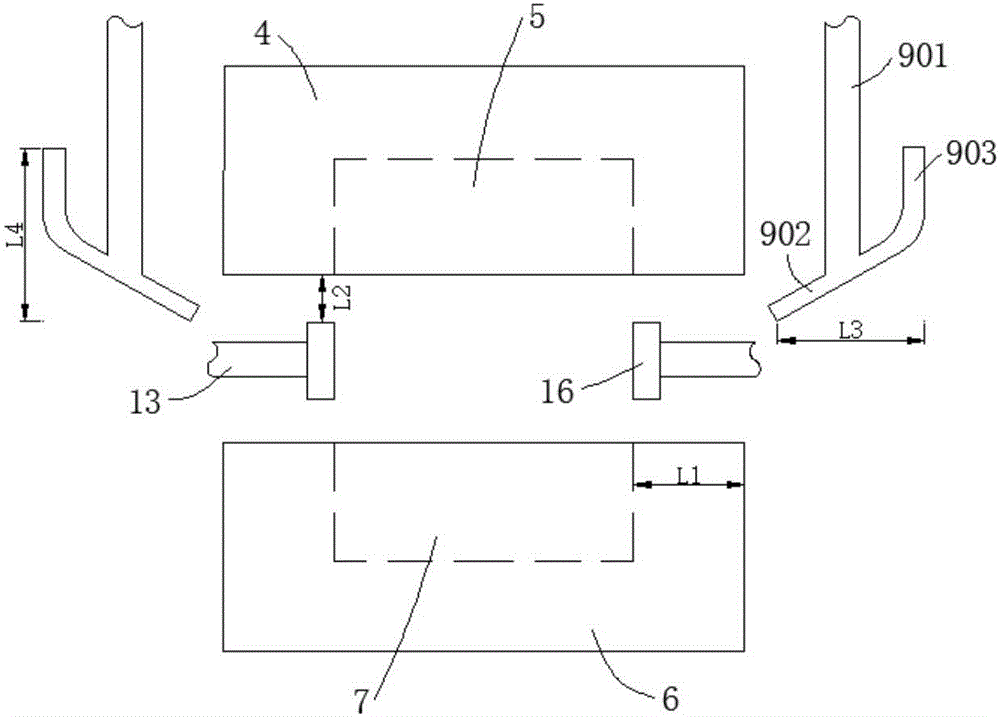

The invention discloses a tailing solid waste resource recycling and reusing treatment device. The tailing solid waste resource recycling and reusing treatment device comprises a charging device, first screening devices, second screening devices, an overlapping prevention conveying device, an ordering conveying device, a colorimeter screening device and a guide plate device which are sequentiallyarranged; the first screening devices are used for carrying out size grading on a mixed material; and the second screening devices are used for separating gangue, coal sheets and coal dust. The tailing solid waste resource recycling and reusing treatment device is reasonable in structural arrangement, a gangue mountain can be automatically filtered and screened, the coal dust, the small-size gangue or the coal sheets, and the large-size gangue or the coal sheets can be effectively separated, and are stored separately, the dirt content of the separated coal dust and coal sheets is relatively low, the integral heating value is increased, ineffective transportation and storage are reduced, the collecting operation is efficient and convenient, water is not required to be used as a screening medium in the whole process, and water resources are saved.

Owner:宋宏亮

Stable imaging method applicable to two-dimensional wide-area scanning

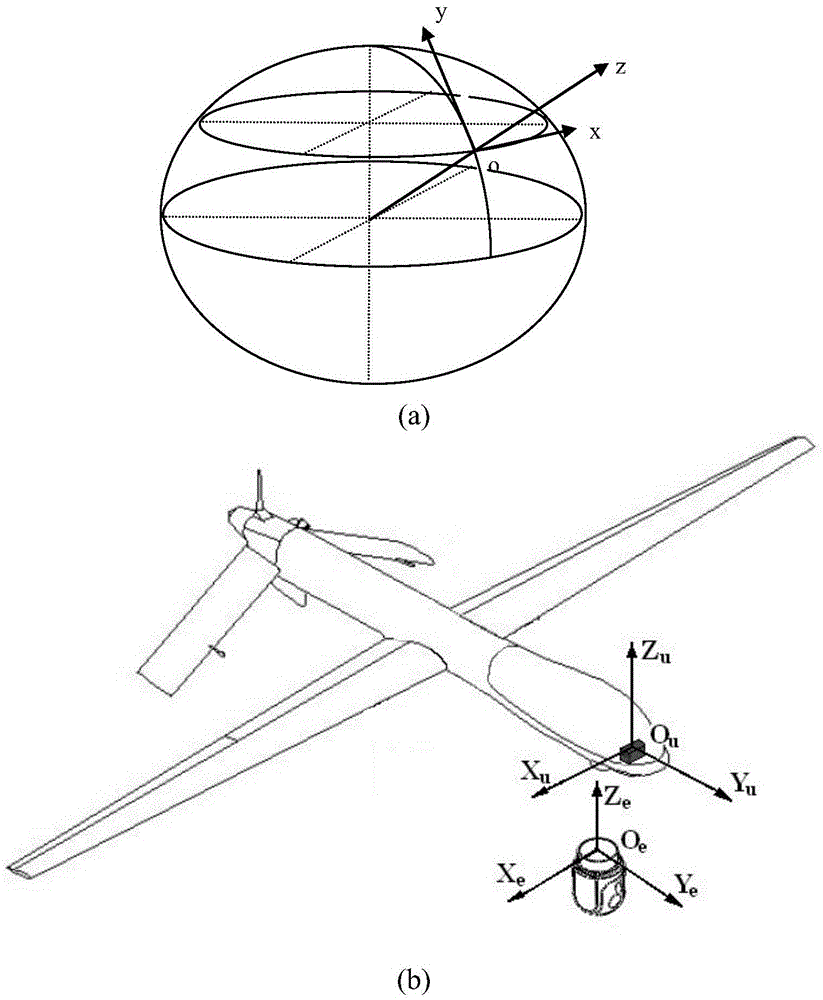

ActiveCN105588564AClear imagingImprove target recognition rateNavigational calculation instrumentsNavigation by speed/acceleration measurementsWide areaImaging quality

The invention provides a stable imaging method applicable to two-dimensional wide-area scanning. The core of the method is geographical stabilization and electron image movement compensation matching, forward movement of a photoelectric system is compensated in a geographical stabilization manner, the movement of the azimuth is compensated in a geographical stabilization and electron image movement combined manner, and clear imaging of the photoelectric system in the two-dimensional wide-area scanning process is finally realized. The method is mainly realized through algorithms, the structural form is simple, the imaging quality of the photoelectric system can be effectively improved, and the reliability of the photoelectric system can be improved.

Owner:西安应用光学研究所

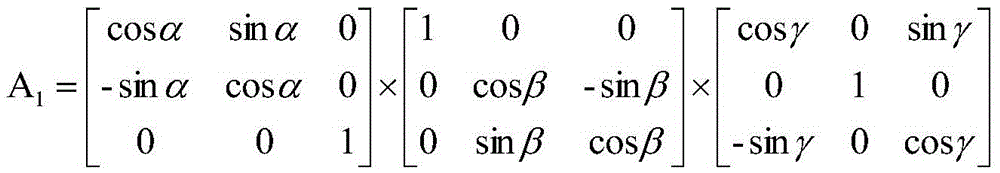

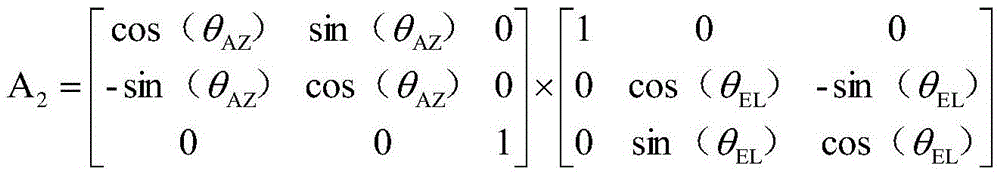

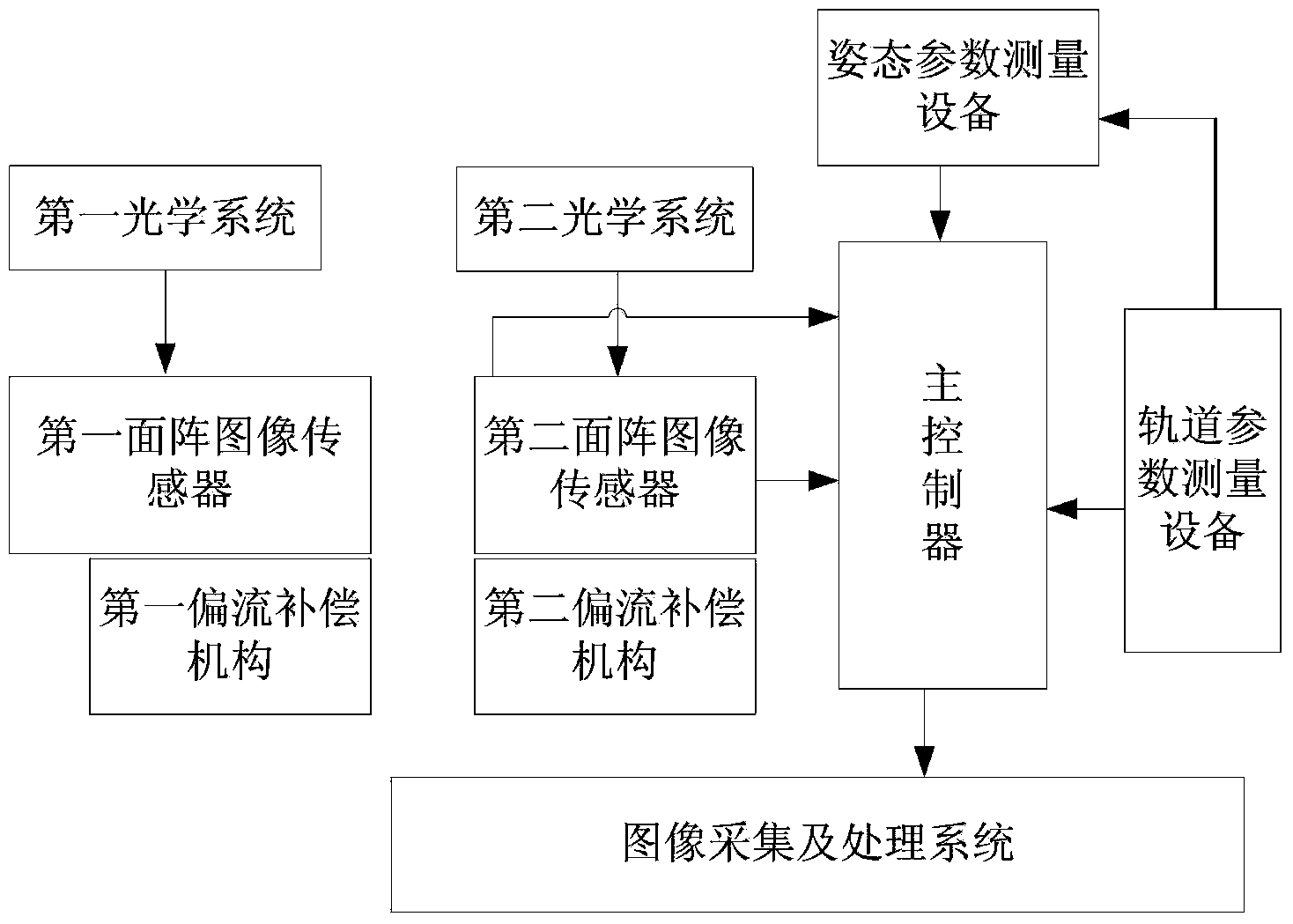

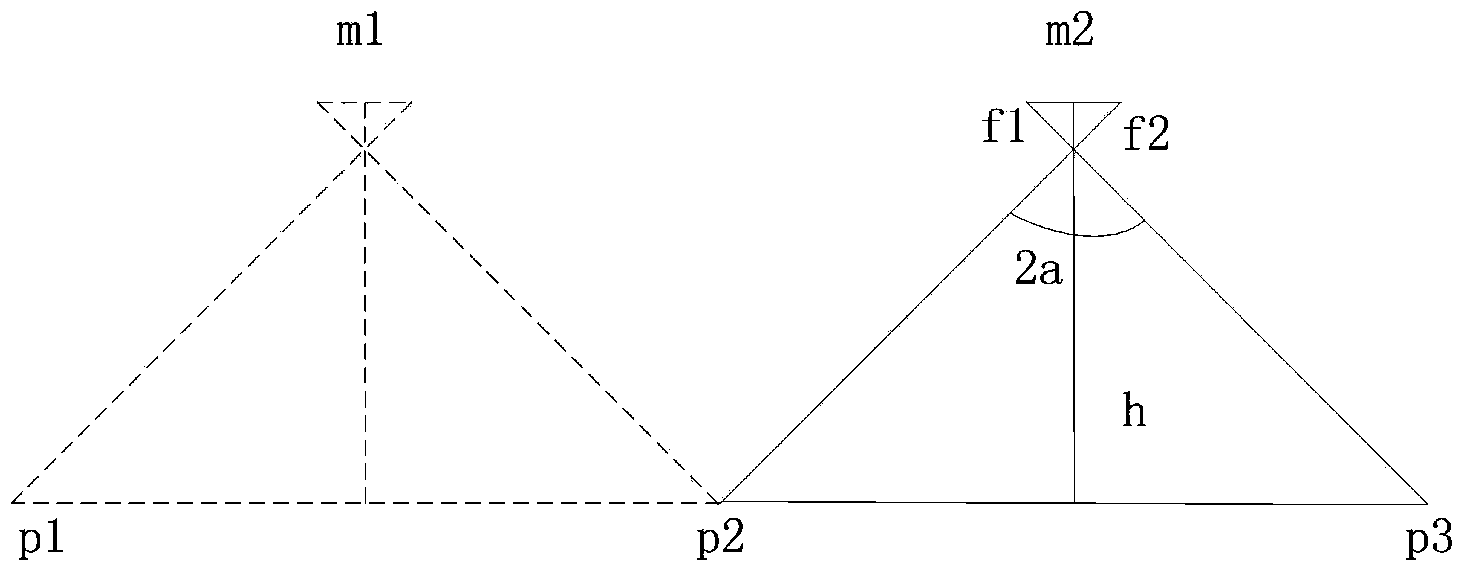

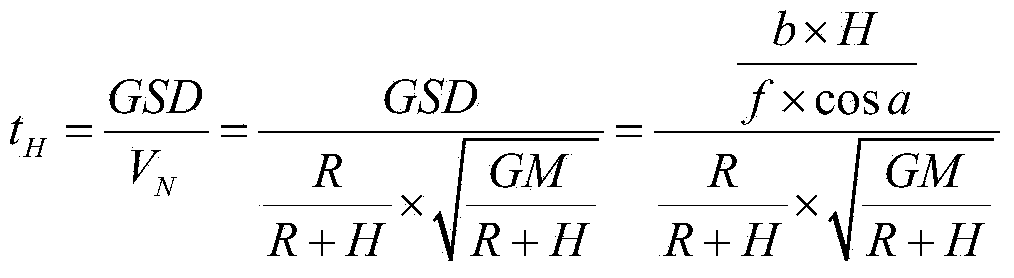

Double-area array push-broom three-dimensional surveying and mapping method and system

InactiveCN104296726AHigh precisionAttitude parameter reductionPicture taking arrangementsCentral projectionOperation mode

The invention discloses a double-area array push-broom three-dimensional surveying and mapping method and a double-area array push-broom three-dimensional surveying and mapping system, and relates to an imaging system, solving the problems that if the existing three-wire array push-broom imaging is adopted, corresponding posture parameters are required for each row of images, and thus the posture measurement velocity is low and the precision is lowered greatly. When the double-sided array push-broom three-dimensional surveying and imaging is carried out, each image meets the central projection principle, and only a group of posture parameters are required for each image, so that the requirement for the posture upgrade rate is lowered; the push-broom three-dimensional surveying and imaging with high base-height ratio is realized by utilizing the double-area array imaging device; the row cycle is set according to the height of a track and the pixel size of a plane array sensor; the maximal frame cycle can be obtained according to the row cycle and the number of columns of the area array sensor; the best frame cycle is calculated according to the height of the track and the included angle of the double-area array optical system; the operation mode of an area array imaging device with high resolution ratio and the included angle of the double-area array optical system are defined.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

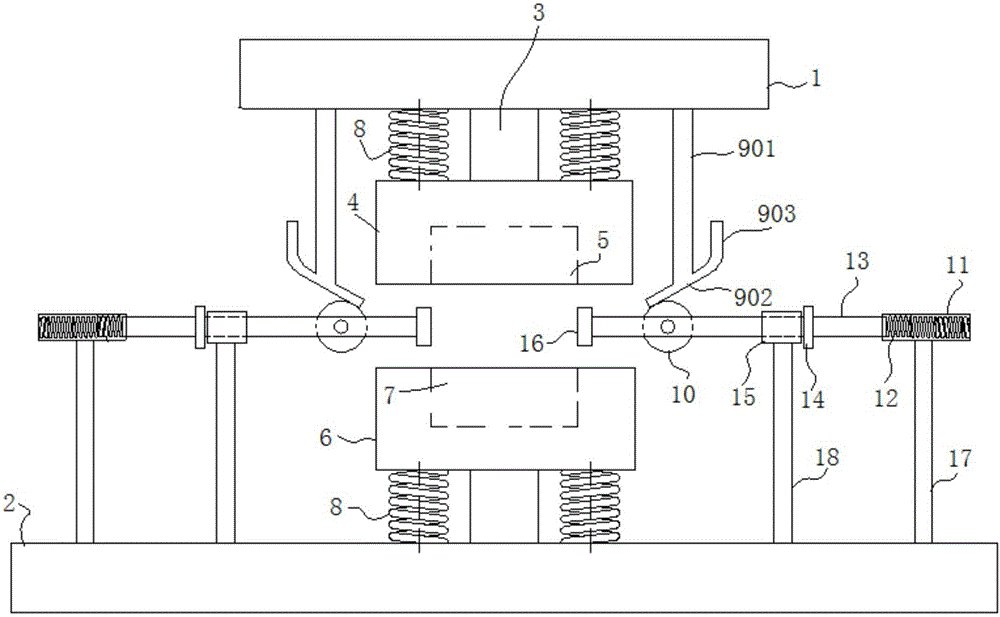

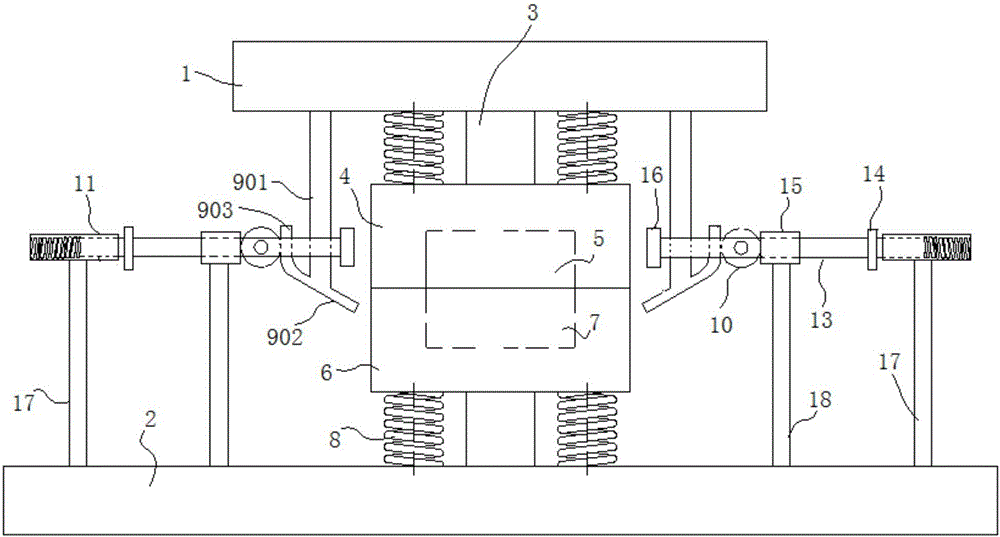

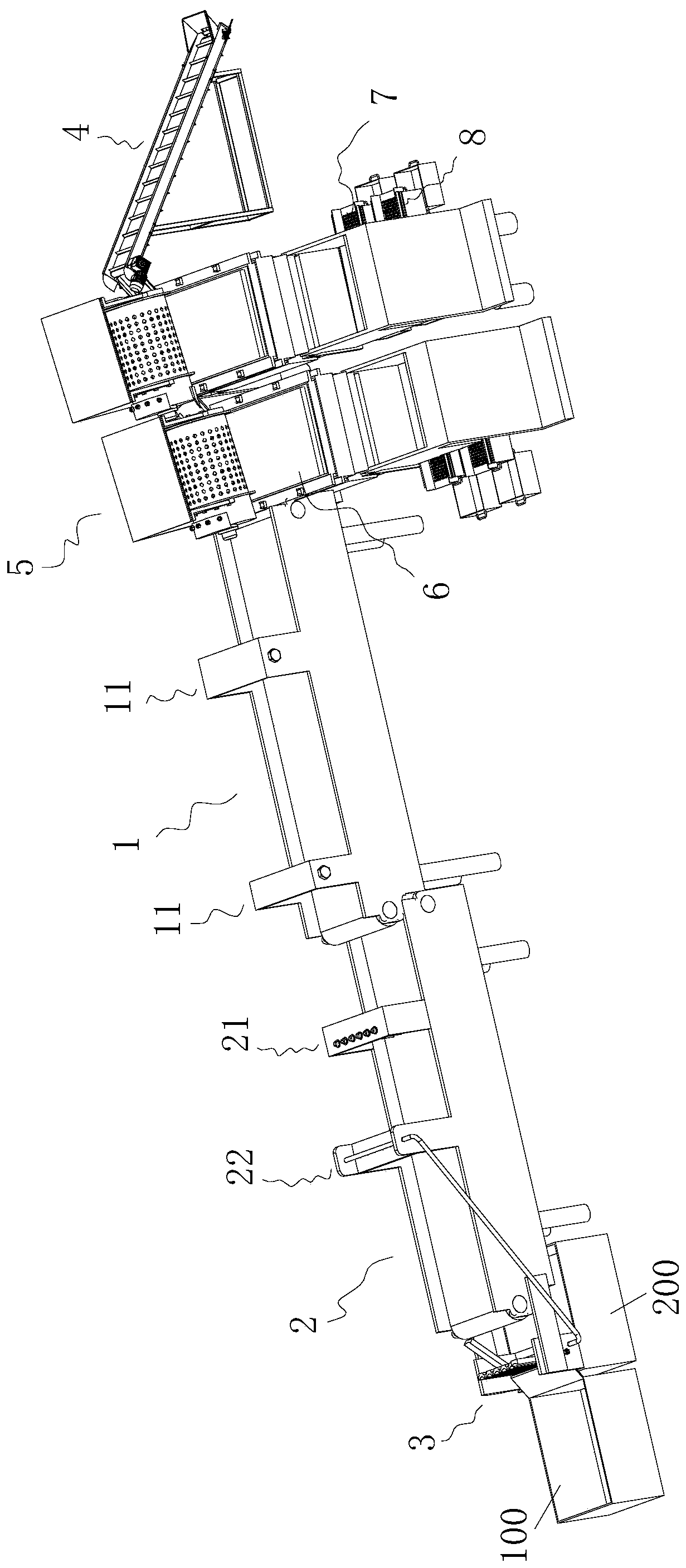

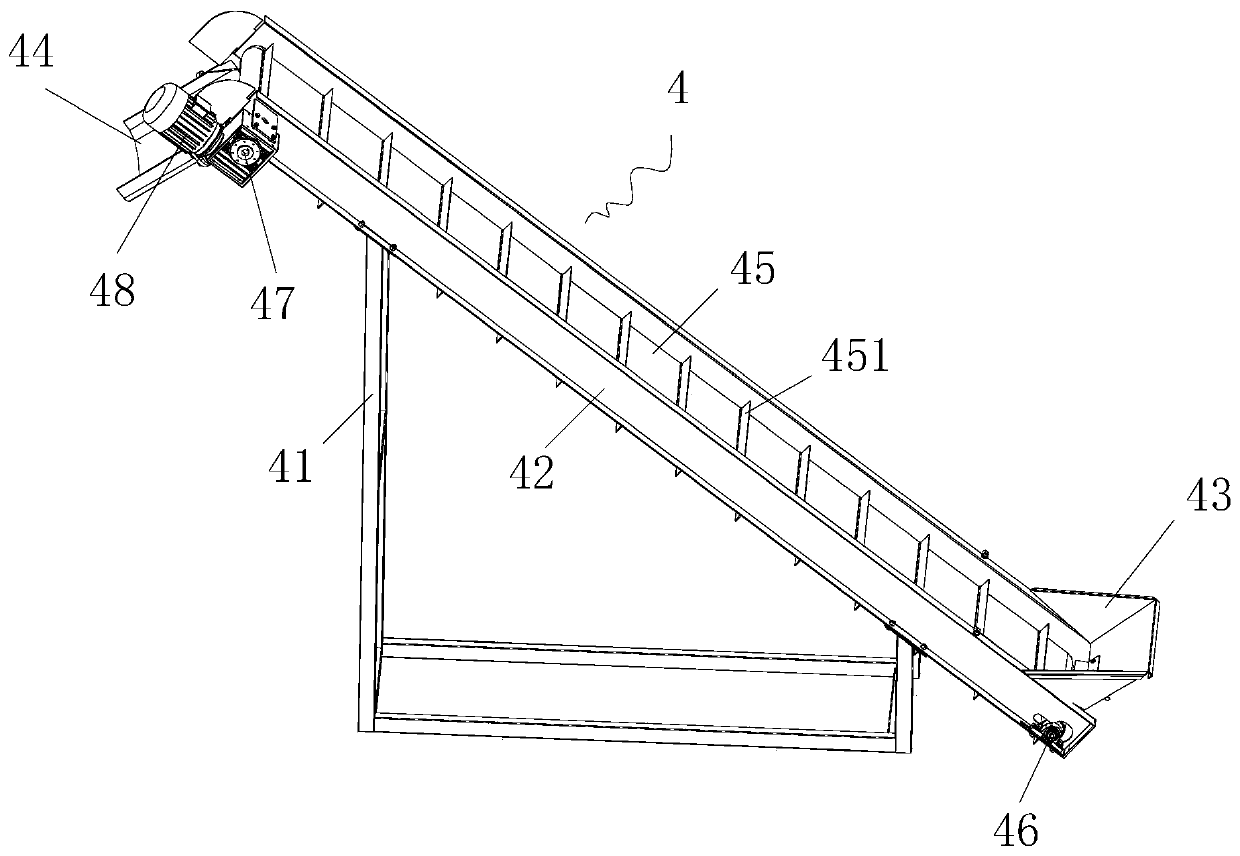

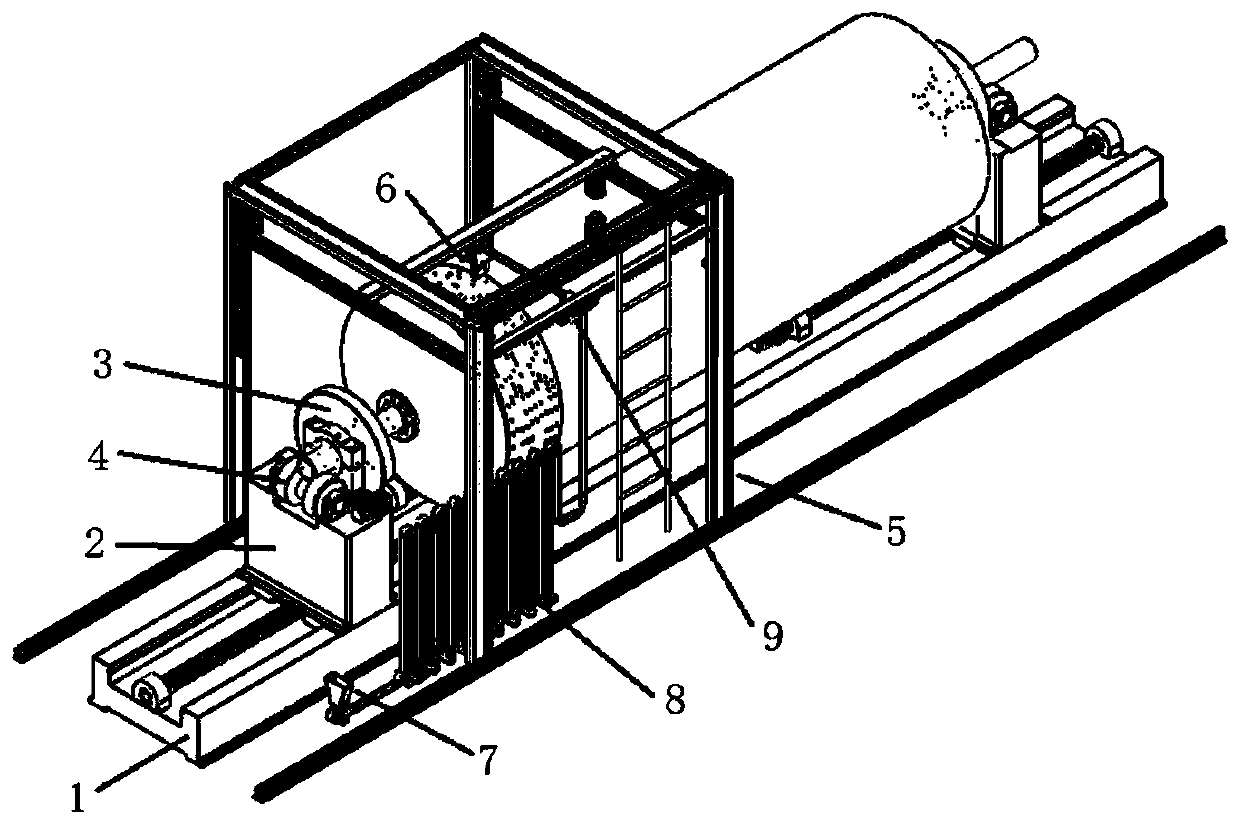

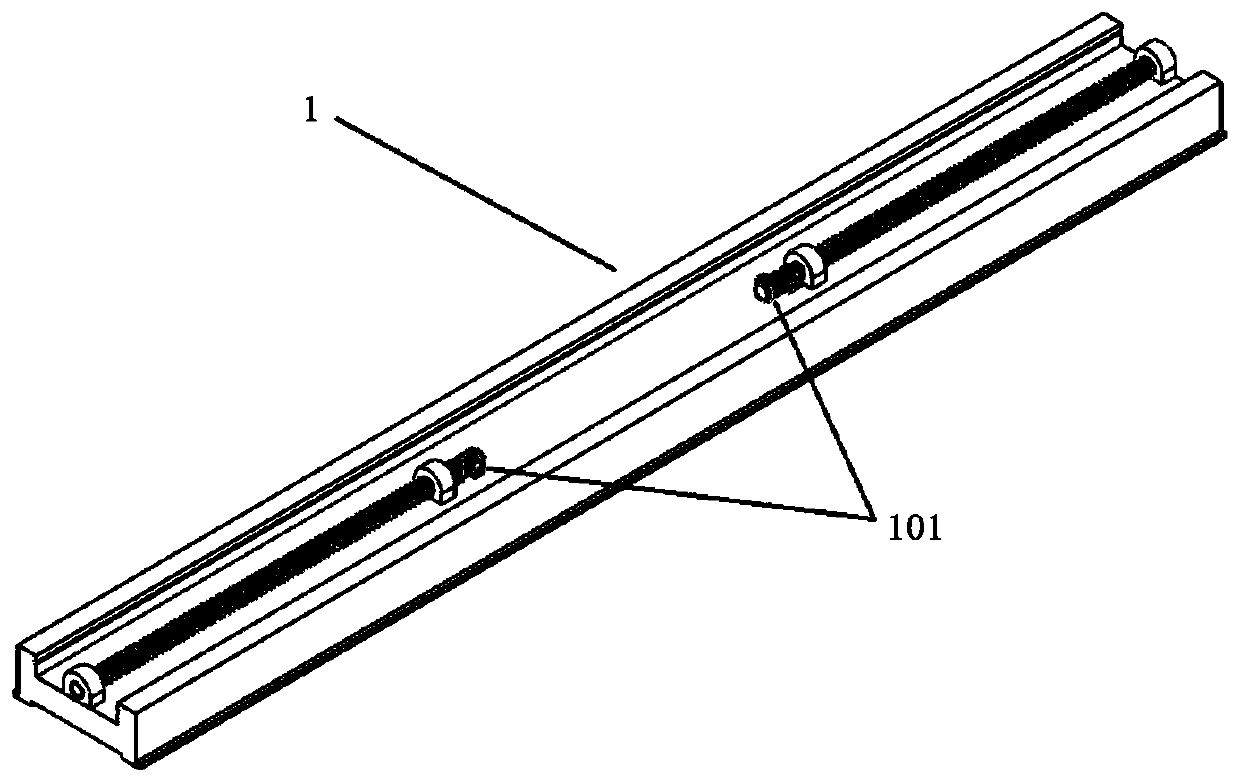

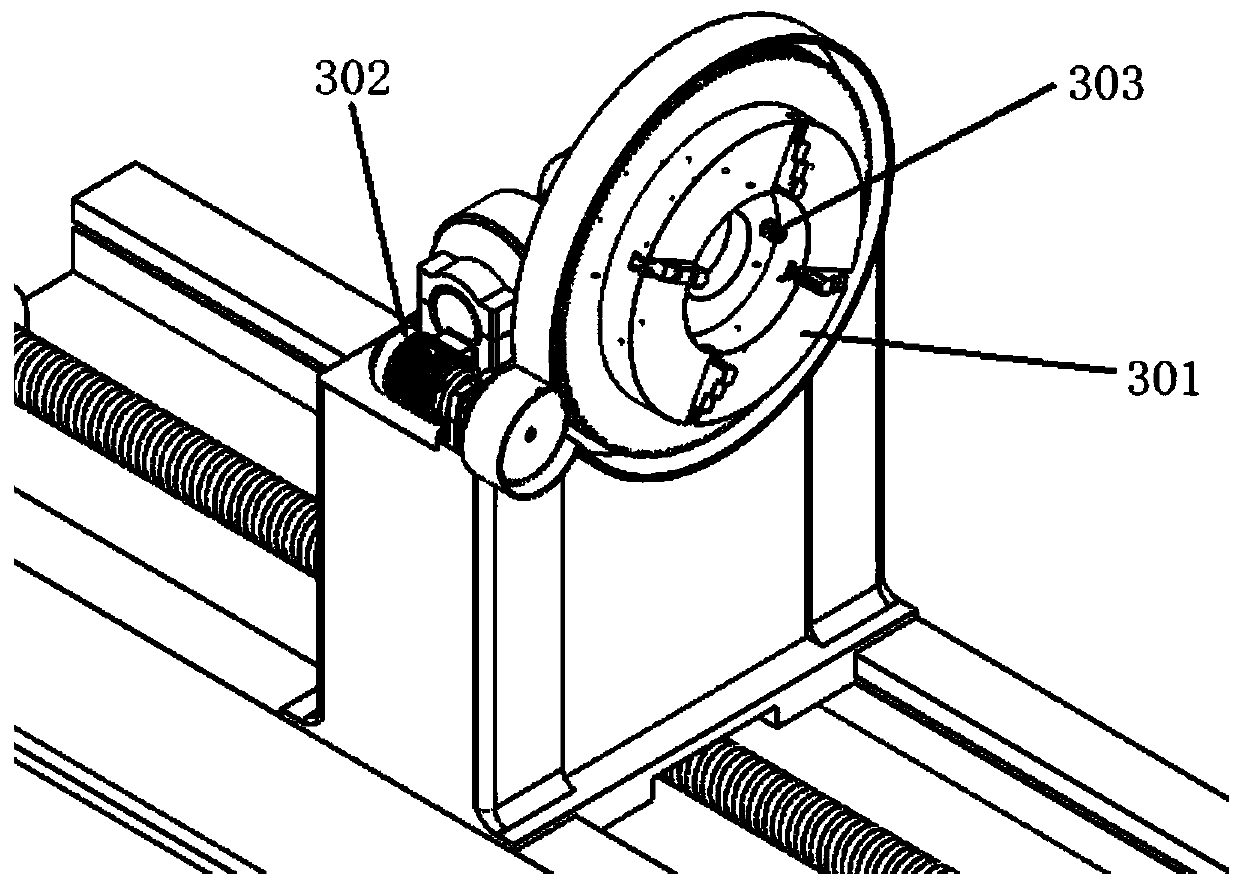

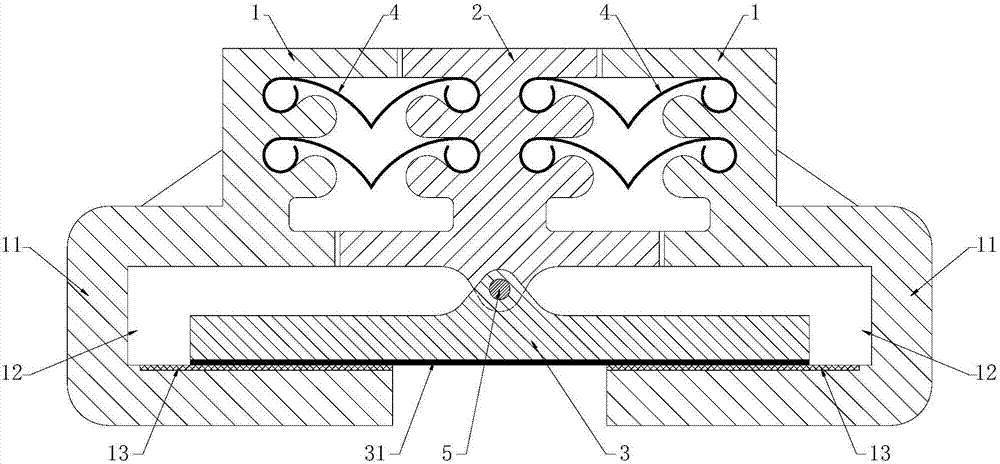

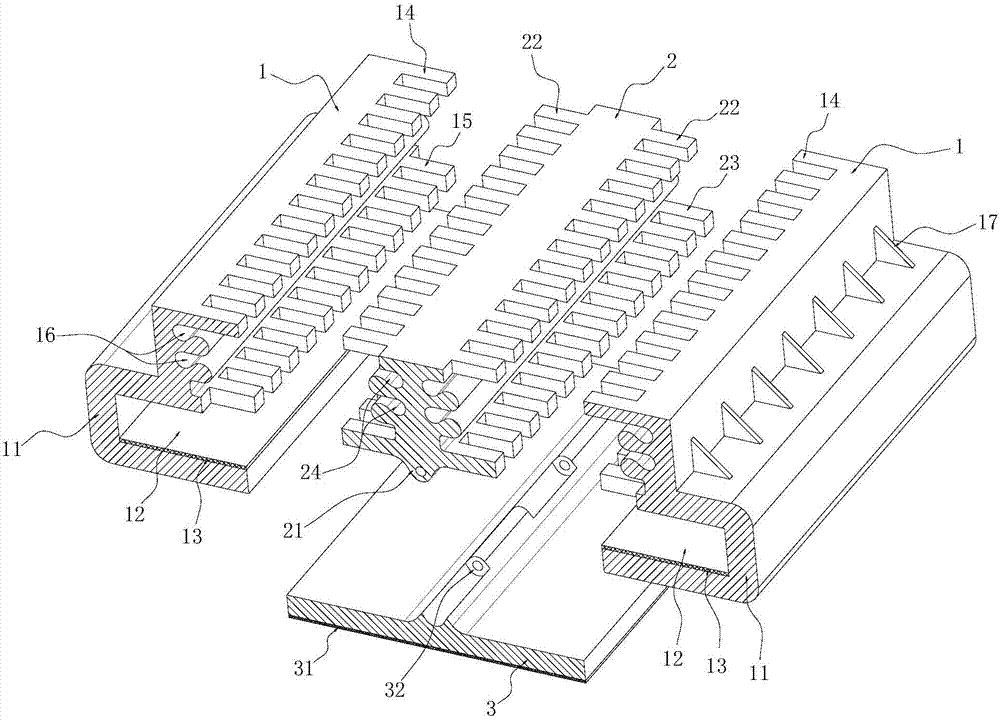

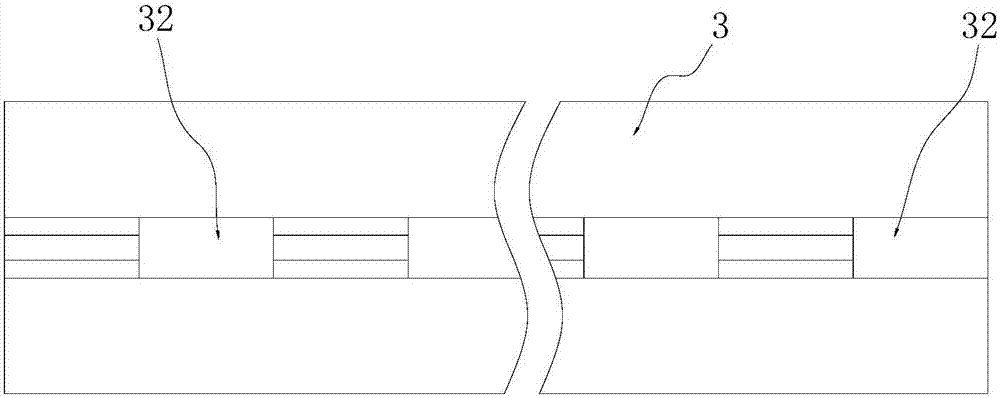

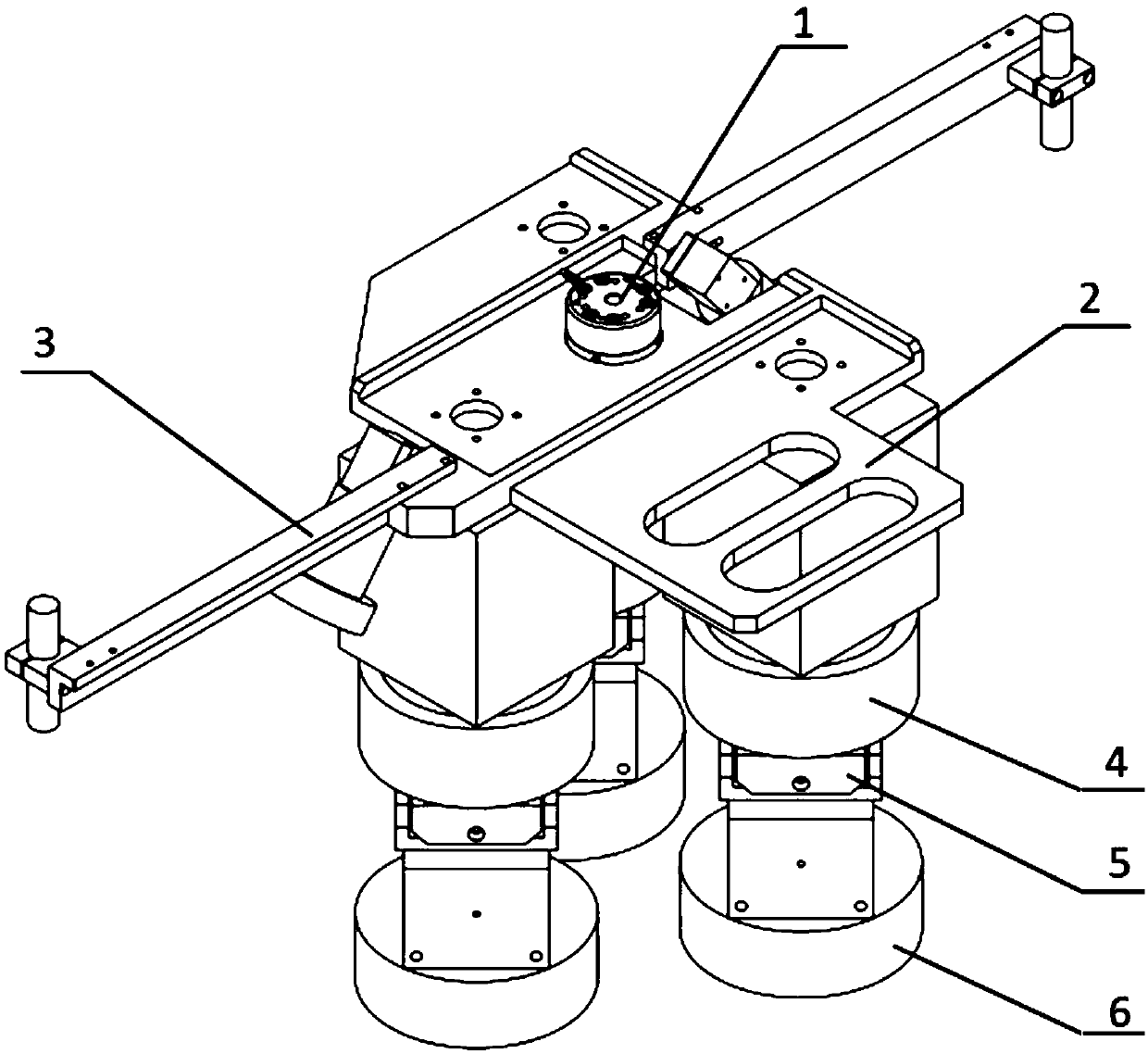

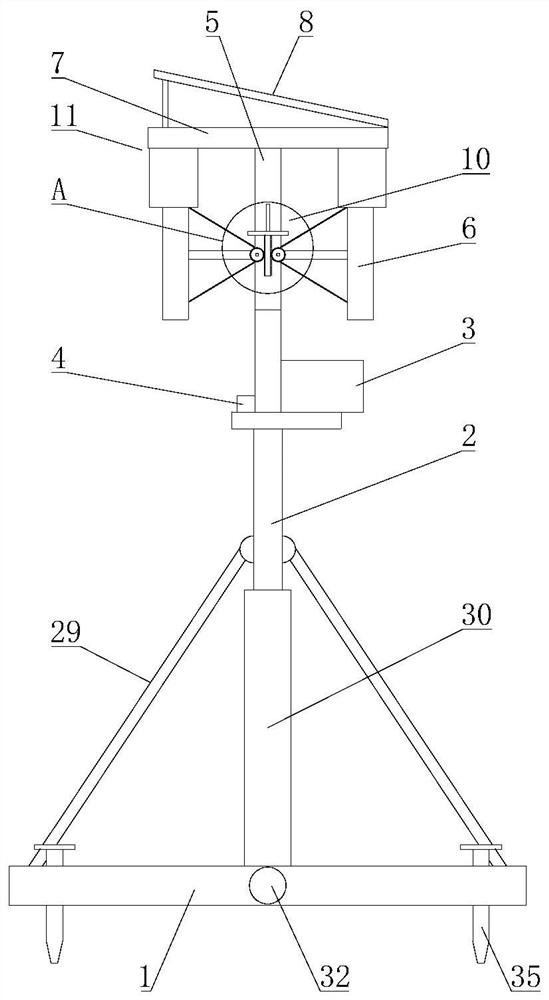

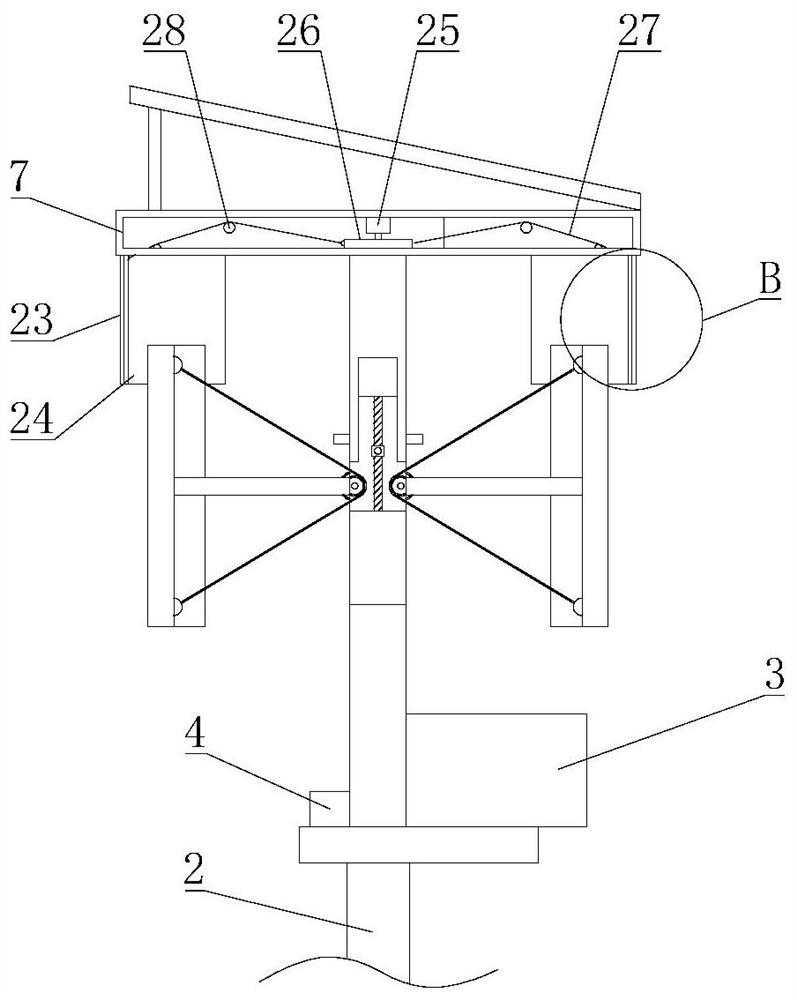

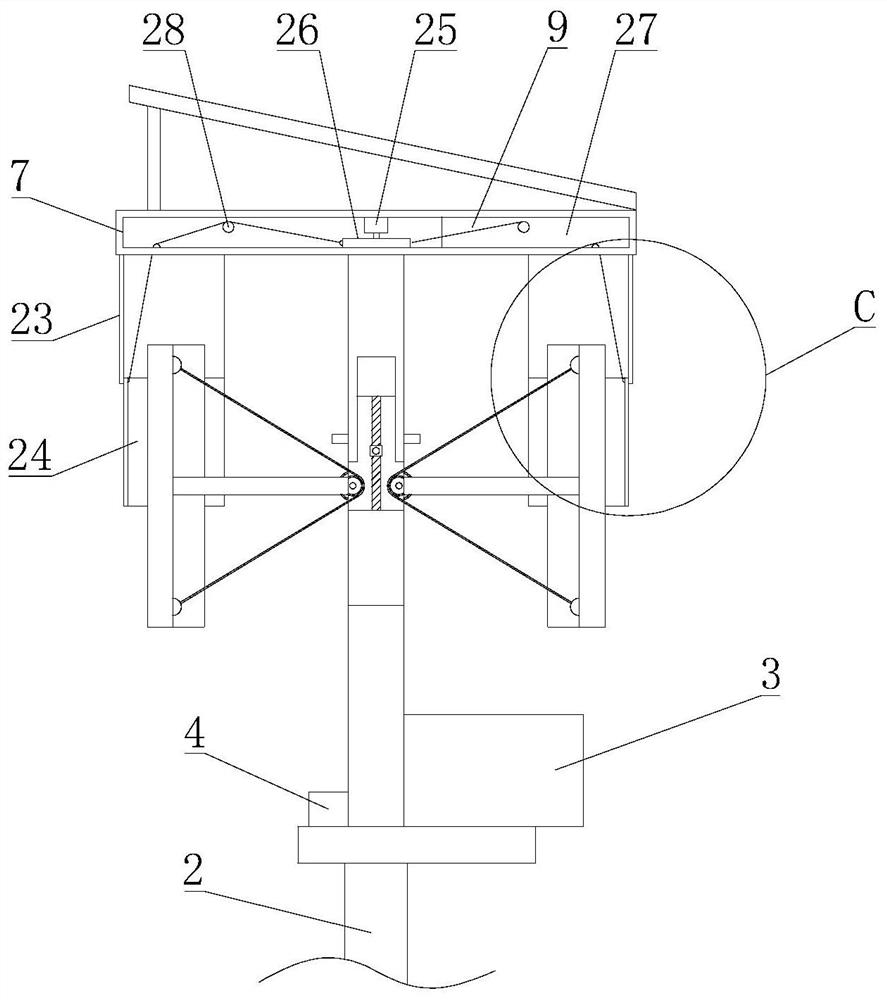

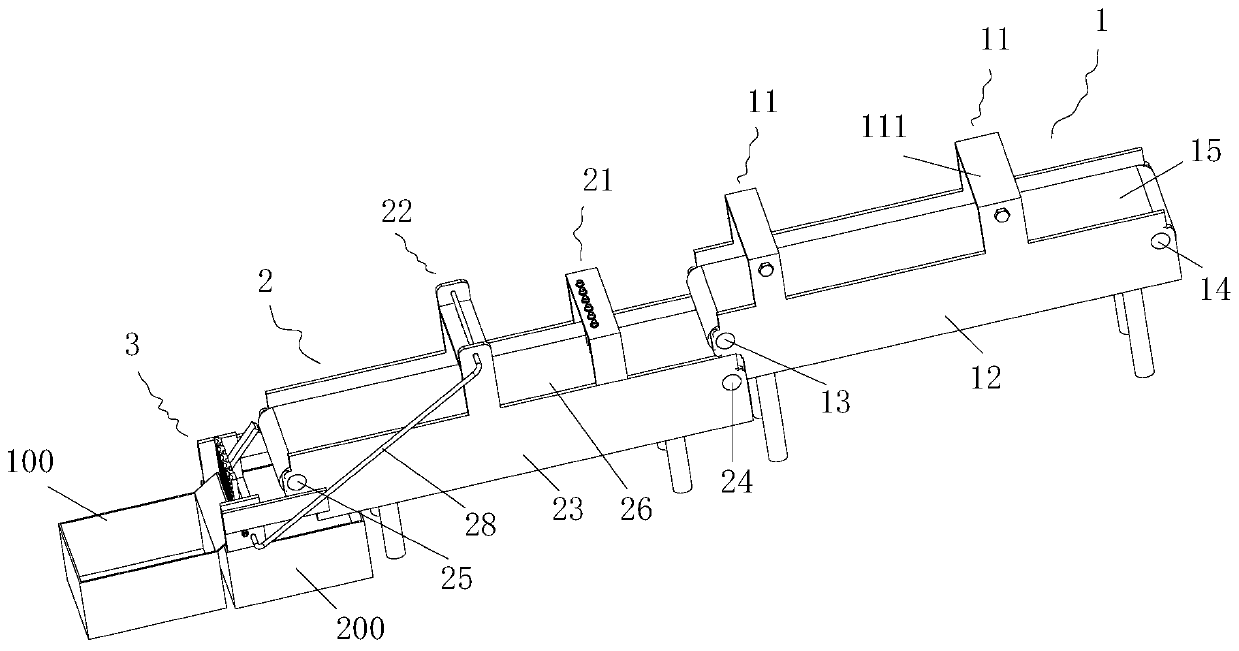

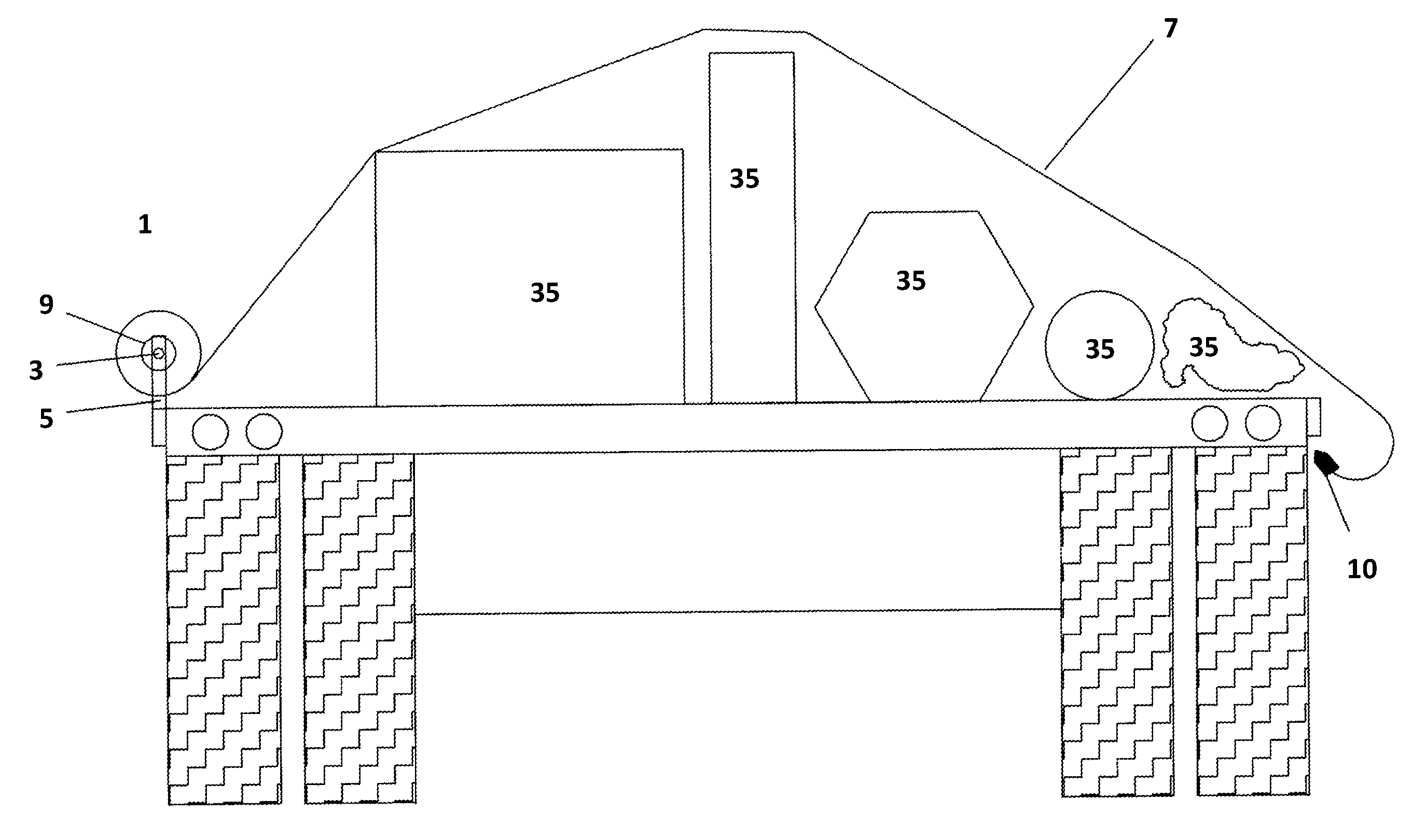

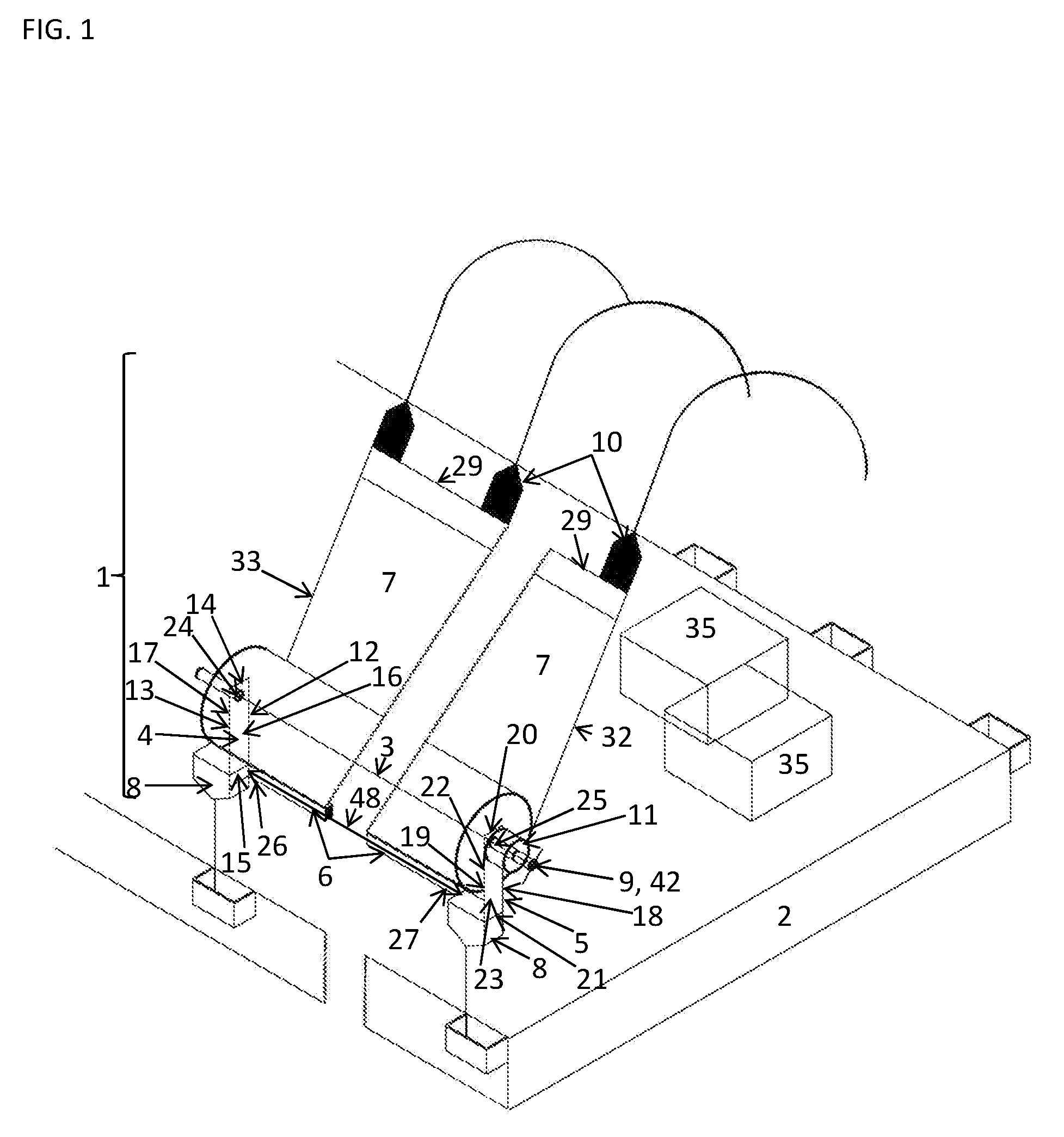

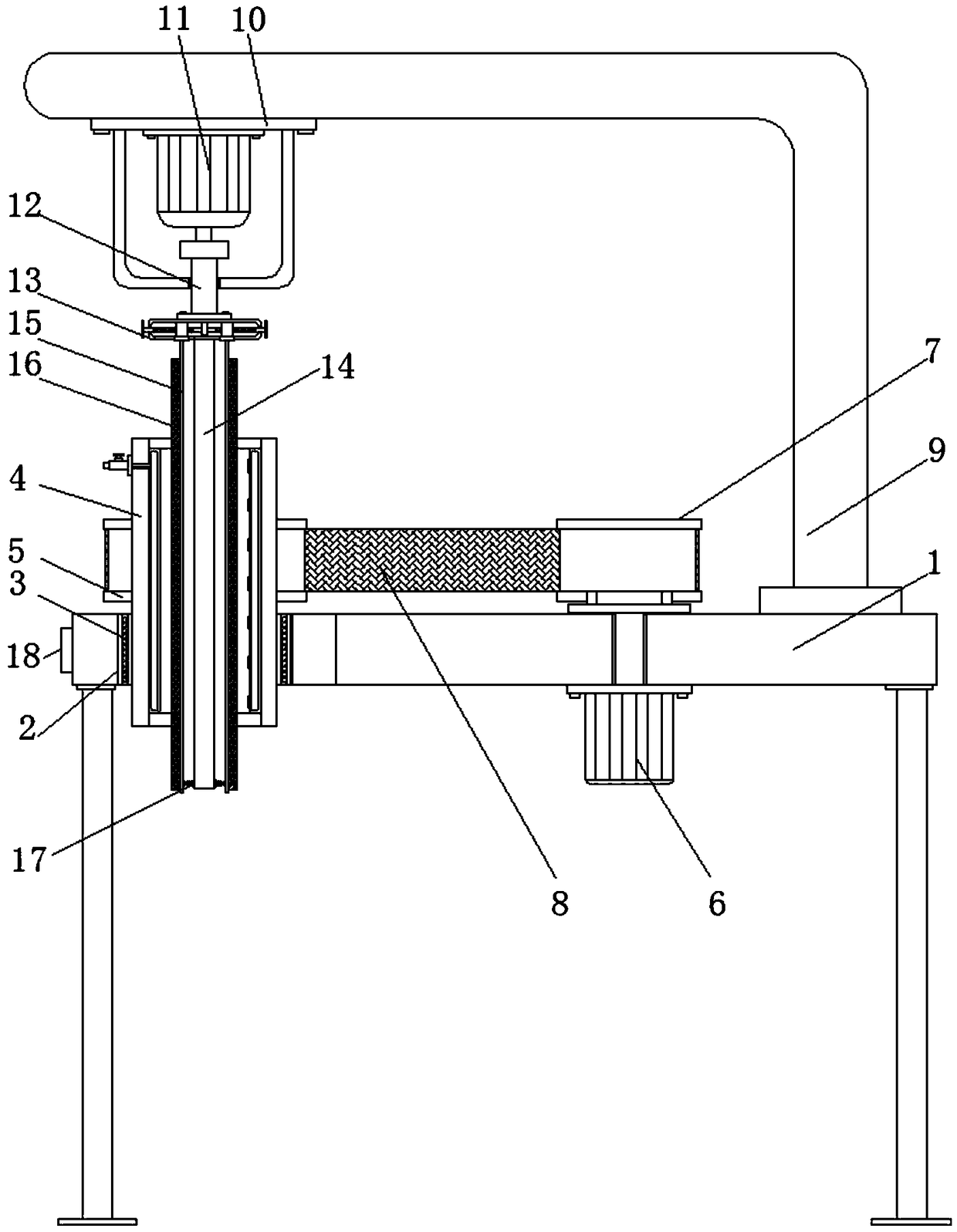

Automatic pasting robot system for rocket engine fuel storage box heat insulation layer

The invention discloses an automatic pasting robot system for a rocket engine fuel storage box heat insulation layer. The system comprises a rack (1), two supporting tables (2) mounted on the rack (1), a rocket storage box end cover clamping and rotating mechanism (3) and a height adjusting mechanism (4) arranged on any one of the supporting table mechanisms (2), a gantry and guide rail (5) erected on the outer sides of the rack (1) and the supporting tables (2), and a gluing mechanism (7), an airing mechanism (8), a material belt separating mechanism (9) and a composite mechanical arm (6) installed on the gantry and guide rail (5), wherein the composite mechanical arm (6) is used for adhering. The automatic pasting robot system of the invention achieves the automatic forming of the rocketengine storage box fuel heat insulation layer.

Owner:XI AN JIAOTONG UNIV

Bridge telescopic device with high applicability

The invention discloses a bridge telescopic device with high applicability. The bridge telescopic device comprises two pieces of boundary beam profile steel, intermediate beam profile steel arranged between the two pieces of boundary beam profile steel, a sliding crossbeam and water stopping adhesive tape. The two pieces of boundary beam profile steel are symmetrically arranged on the left side and the right side of the intermediate beam profile steel. The intermediate beam profile steel and the two pieces of boundary beam profile steel are connected in a meshing mode through comb teeth. The bottoms of the two pieces of boundary beam profile steel are provided with sliding boxes. Each sliding box is internally provided with a sliding cavity. The left and right sides of the sliding crossbeam are erected in the sliding cavity of the left boundary beam profile steel and the sliding cavity of the right boundary beam profile steel. The upper end of the sliding crossbeam are movably hinged to the bottom of the intermediate beam profile steel. The water stopping adhesive tape is connected between the intermediate beam profile steel and the left boundary beam profile steel and between the intermediate beam profile steel and the right boundary beam profile steel. According to the bridge telescopic device with the high applicability, by adopting the structure mode that the intermediate beam profile steel is arranged between the two pieces of boundary beam profile steel, the device has high telescopic performance, the large displacement and inclination displacement can be met, and the smooth running performance of the vehicle is improved.

Owner:浙江秦山橡胶工程股份有限公司

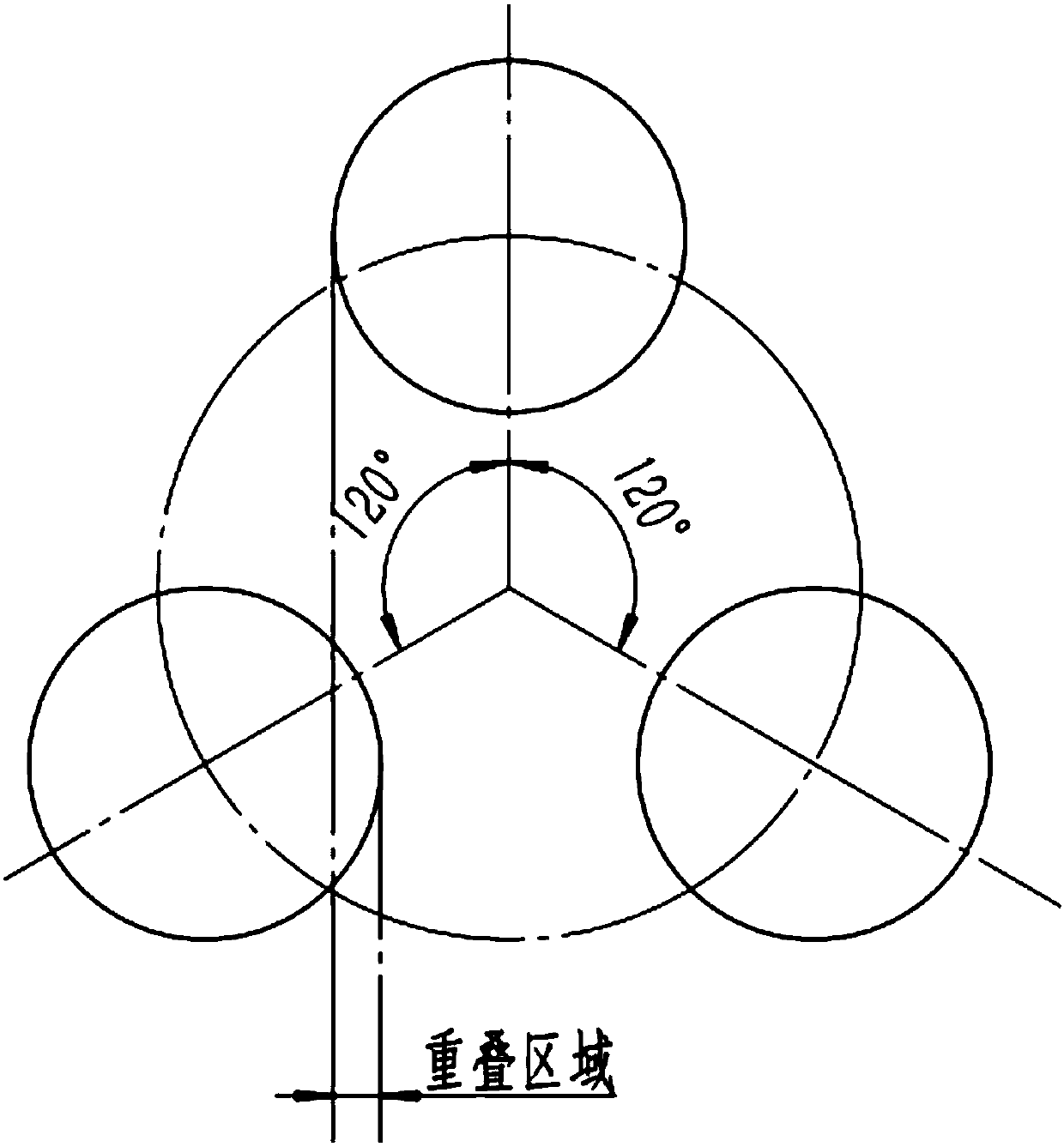

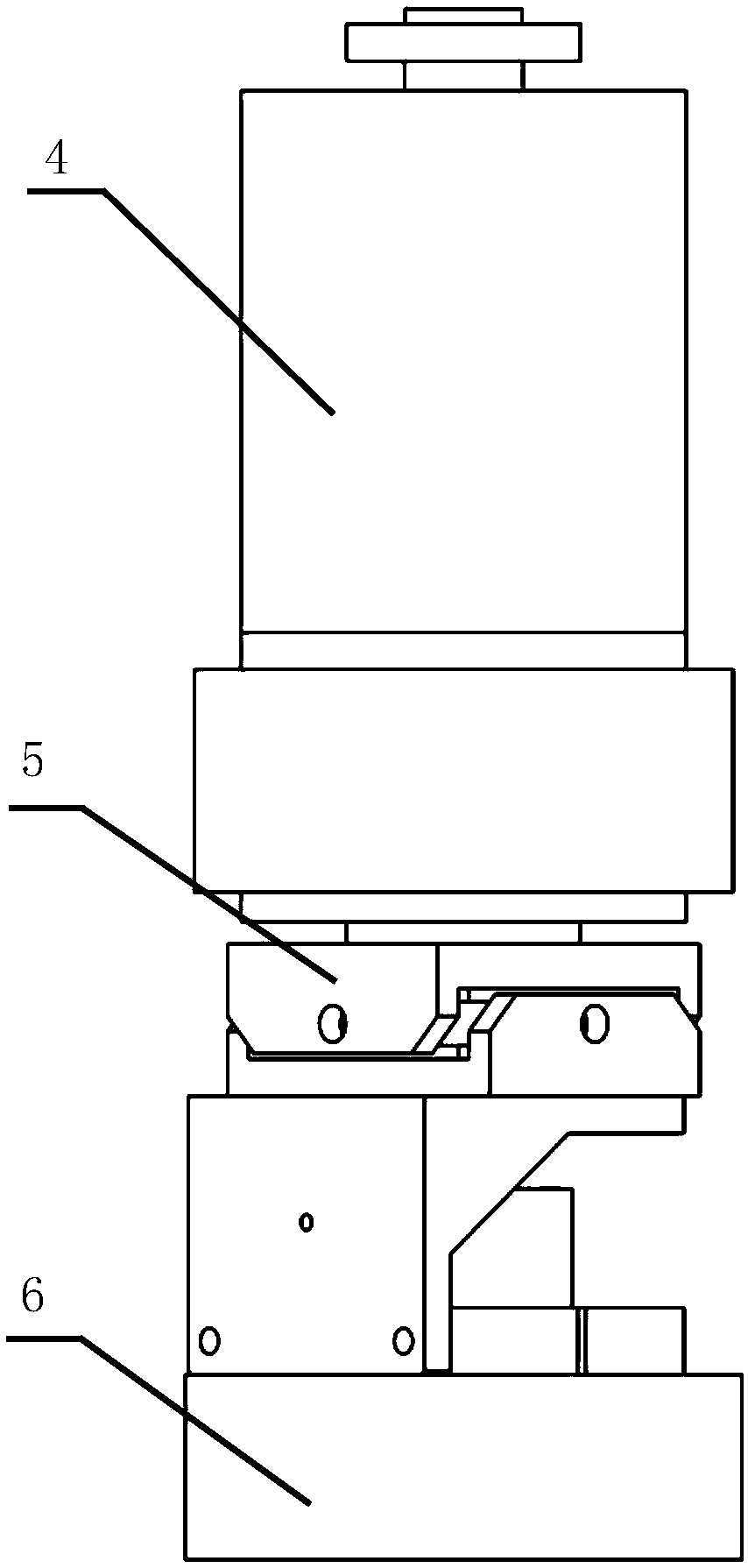

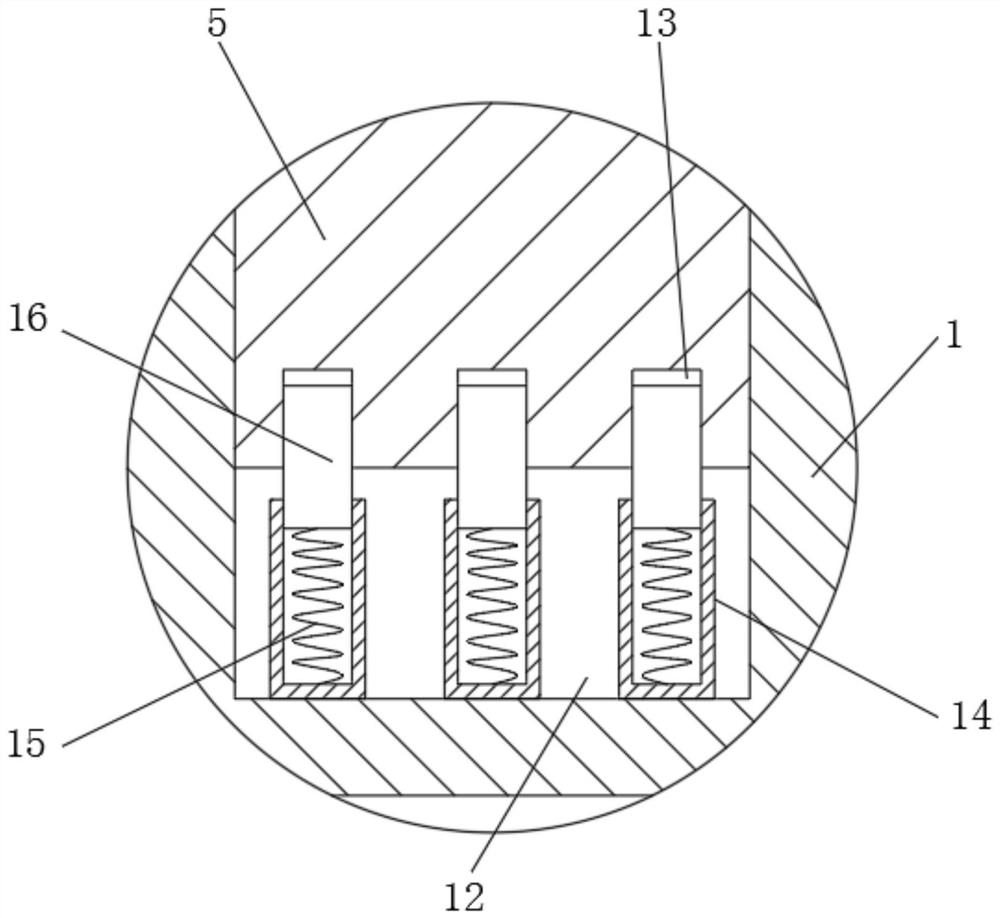

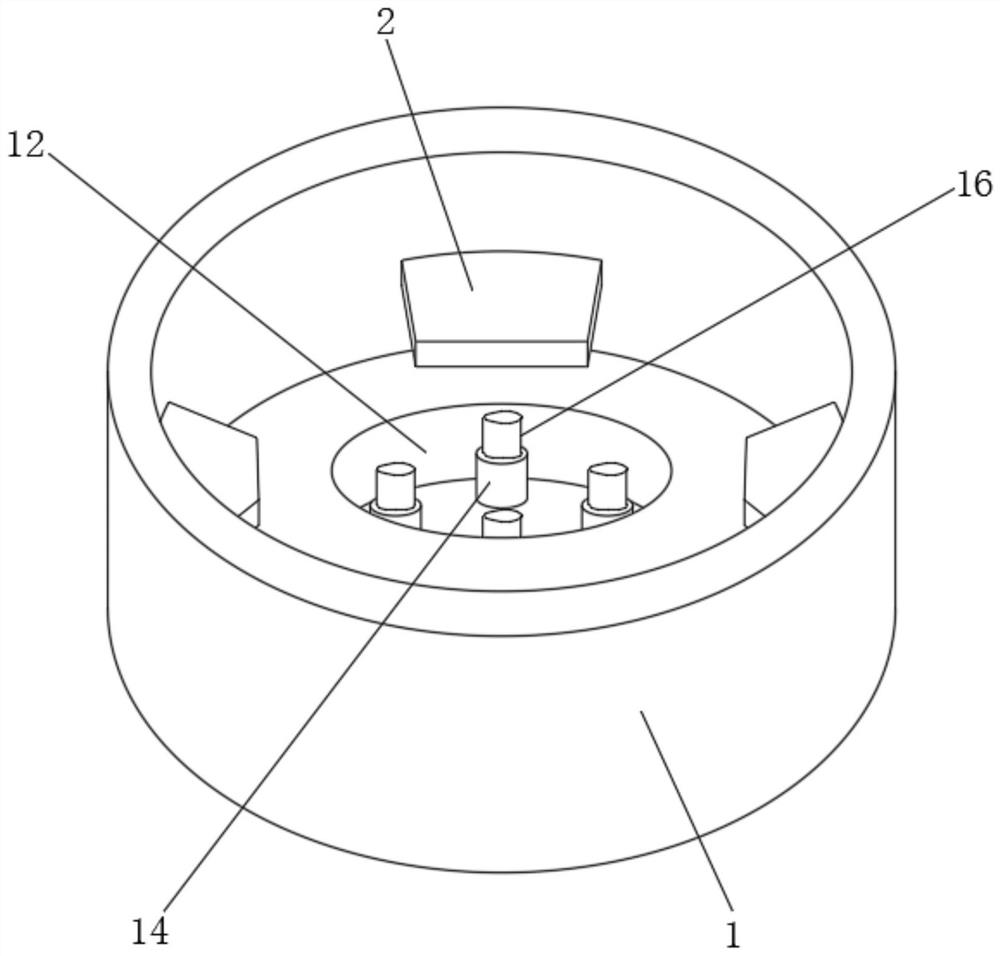

Intelligent grinding device based on force control and visual technology

ActiveCN111390722AEnsure coordinationImprove sanding surface effectGrinding feed controlGrinding machinesGrindingObstacle avoidance

The invention discloses an intelligent grinding device based on force control and a vision technology, and belongs to the technical field of automatic grinding and polishing equipment. The grinding device comprises a six-dimensional force sensor, an industrial vision assembly, constant force actuators, passive adjusting devices, a connecting piece and a grinding assembly, wherein the six-dimensional force sensor is fixed on the connecting piece; three through holes are formed in the connecting piece and are uniformly distributed on the circumference taking the six-dimensional force sensor as the center, and three through holes fix the grinding assembly correspondingly; the grinding assembly comprises grinding heads, the passive adjusting devices and the constant force actuators, and the grinding heads are connected with the constant force actuators through the passive adjusting devices; and the industrial vision assembly is used for detecting whether a grinding obstacle exists in the grinding advancing direction or not in real time, and the obstacle avoidance effect is achieved. The invention provides the efficient intelligent grinding device based on the force control and the vision technology being efficient, safe and good in grinding effect for automatic grinding and polishing, and the automation level and the intelligent level in the grinding and polishing process are improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

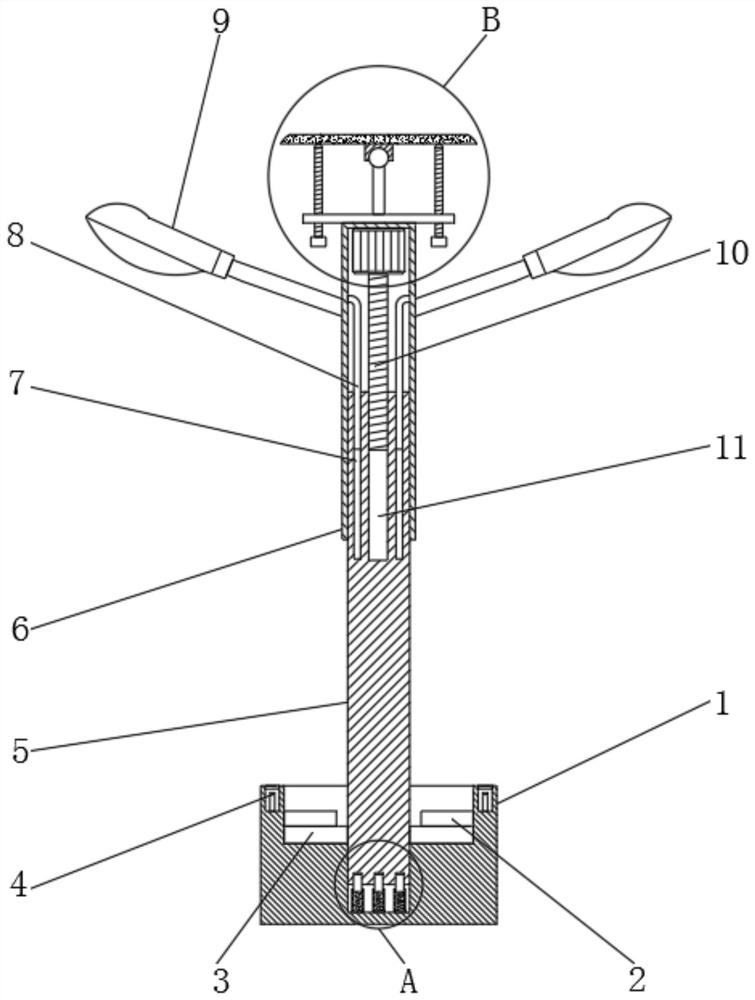

Intelligent urban solar street lamp

ActiveCN112377867AIntelligent adjustment of light intensityGuaranteed overlapPhotovoltaic supportsMechanical apparatusElectric machineSolar street light

The invention discloses an intelligent urban solar street lamp. The intelligent urban solar street lamp comprises a base and a lamp post. A slot is formed in the inner wall of the bottom of the base,and the lamp post is inserted into the slot. The outer wall of the lamp post is sleeved with a lamp barrel, illuminating lamps are fixedly connected to the outer walls of the two sides of the lamp barrel. A stepping motor is arranged on the inner wall of the top of the lamp barrel, and a lead screw is arranged at one end of an output shaft of the stepping motor. A threaded groove is formed in thetop end of the lamp post, and the outer wall of the lead screw is in threaded connection with the inner wall of the threaded groove. A photovoltaic mechanism is arranged on the outer wall of the top of the lamp barrel, a fixing mechanism is arranged in the base, and limiting rods are fixedly connected to the inner walls of the periphery of the lamp barrel. The illumination intensity of the illuminating lamps can be intelligently adjusted according to the surrounding environment, the energy-saving and environment-friendly requirements are met, the using effect is better, the illuminating lampscannot be detached from the outside, the street lamp has a certain anti-theft effect, a traditional bolt fixing mode is replaced, and the whole street lamp is more stable.

Owner:BEIJING TELECOM PLANNING & DESIGNING INST +1

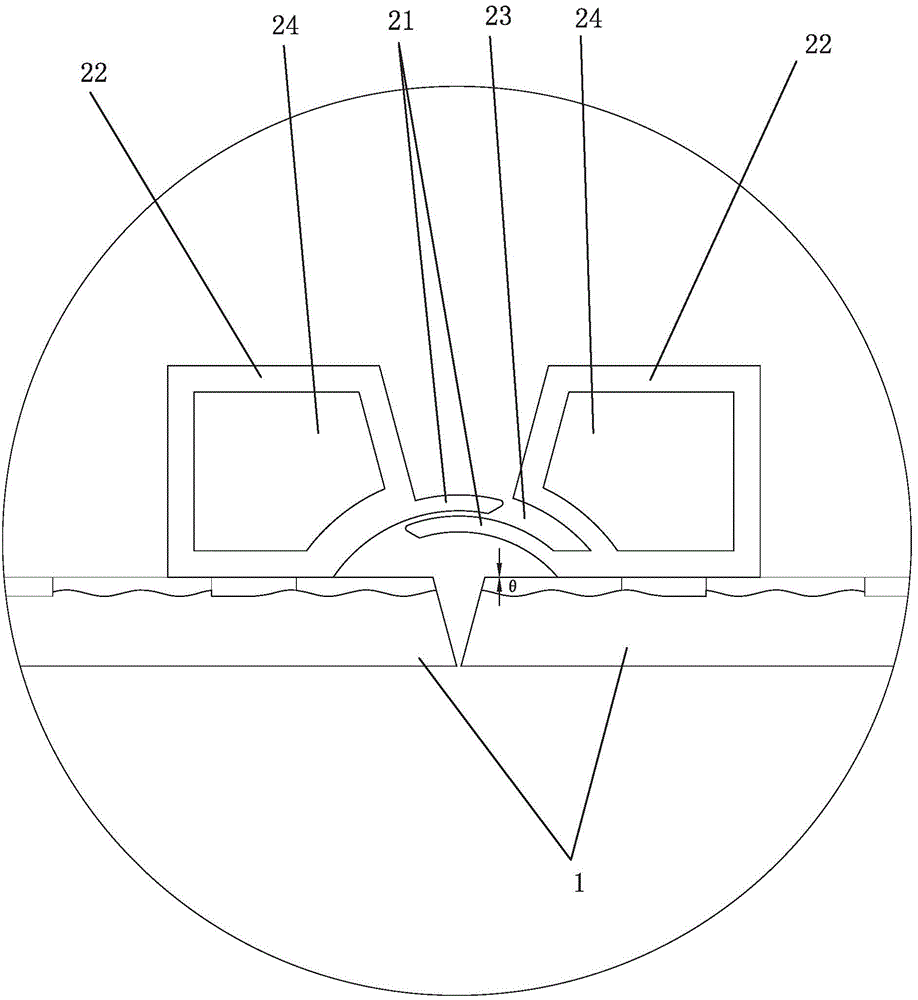

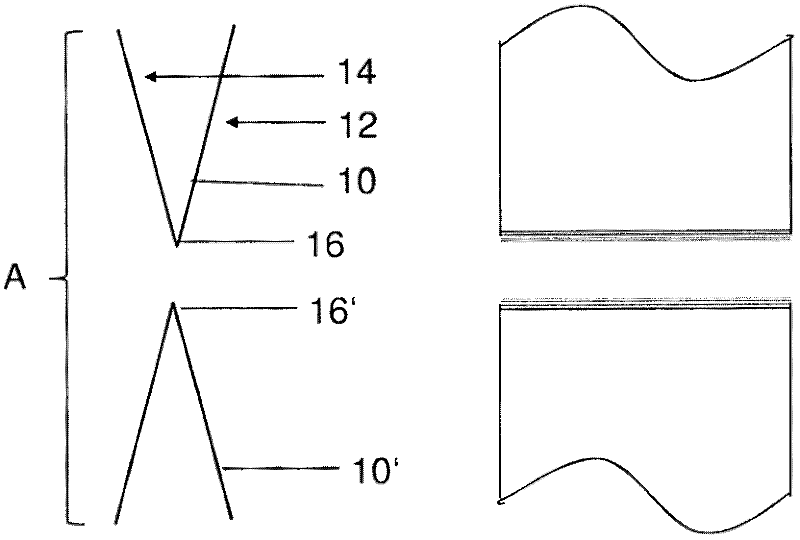

Light-shading type LED screen

ActiveCN104537961AGuaranteed shading effectGuaranteed overlapStands/trestlesIdentification meansEngineeringLED display

The invention belongs to the technical field of LED display, and provides a light-shading type LED screen which comprises two screen body frames and two light-shading bars installed on the adjacent sides of the two screen body frames respectively. Each light-shading bar extends to form an arc-shaped blocking portion, and the arc radius of one blocking portion is smaller than that of the other blocking portion. When the two screen body frames are spliced on a plane or spliced obliquely, the two blocking portions are at least partly overlapped. According to the light-shading LED screen, the light-shading bars with the blocking portions of different arc radiuses are installed on the adjacent sides of the two screen body frames respectively, and it is always guaranteed that the two blocking portions are at least overlapped partly so that the light-shading performance of a screen body can be well guaranteed during splicing, the structure is simple, and assembly is easy.

Owner:SHENZHEN UNIVIEW LED

Angle-adjustable windproof 5G antenna equipment

PendingCN113013612AGuaranteed signal strengthAvoid damageAntenna supports/mountingsRadiating element housingsElectric machineryEngineering

An angle-adjustable windproof 5G antenna device relates to the field of communication equipment, and comprises a base, a mounting rod, a controller, a first driving motor, a rotating rod, an antenna, a mounting seat, a solar cell panel and a current condenser. The mounting rod is arranged on the base; a rotating rod driven by a first driving motor is rotationally arranged on the mounting rod; the antenna is arranged at the side part of the rotating rod; the mounting seat is arranged at the upper part of the rotating rod; the solar cell panel is arranged on the mounting seat and is electrically connected with the storage battery; the device further comprises an angle adjusting assembly and a windproof assembly. The angle adjusting assembly is arranged, and the antenna is pulled by the chain to deflect to a set angle, so that the signal strength is ensured; the windproof assembly is arranged to drive the second windproof cover to slide along the first windproof cover, shielding is provided for the antenna, the antenna is prevented from being damaged, and signal stability is guaranteed; and the height adjusting assembly is arranged to adjust the height of the antenna, so the overlapping property of the antenna position and the detected optimal signal position is ensured.

Owner:深圳多为智联科技有限公司

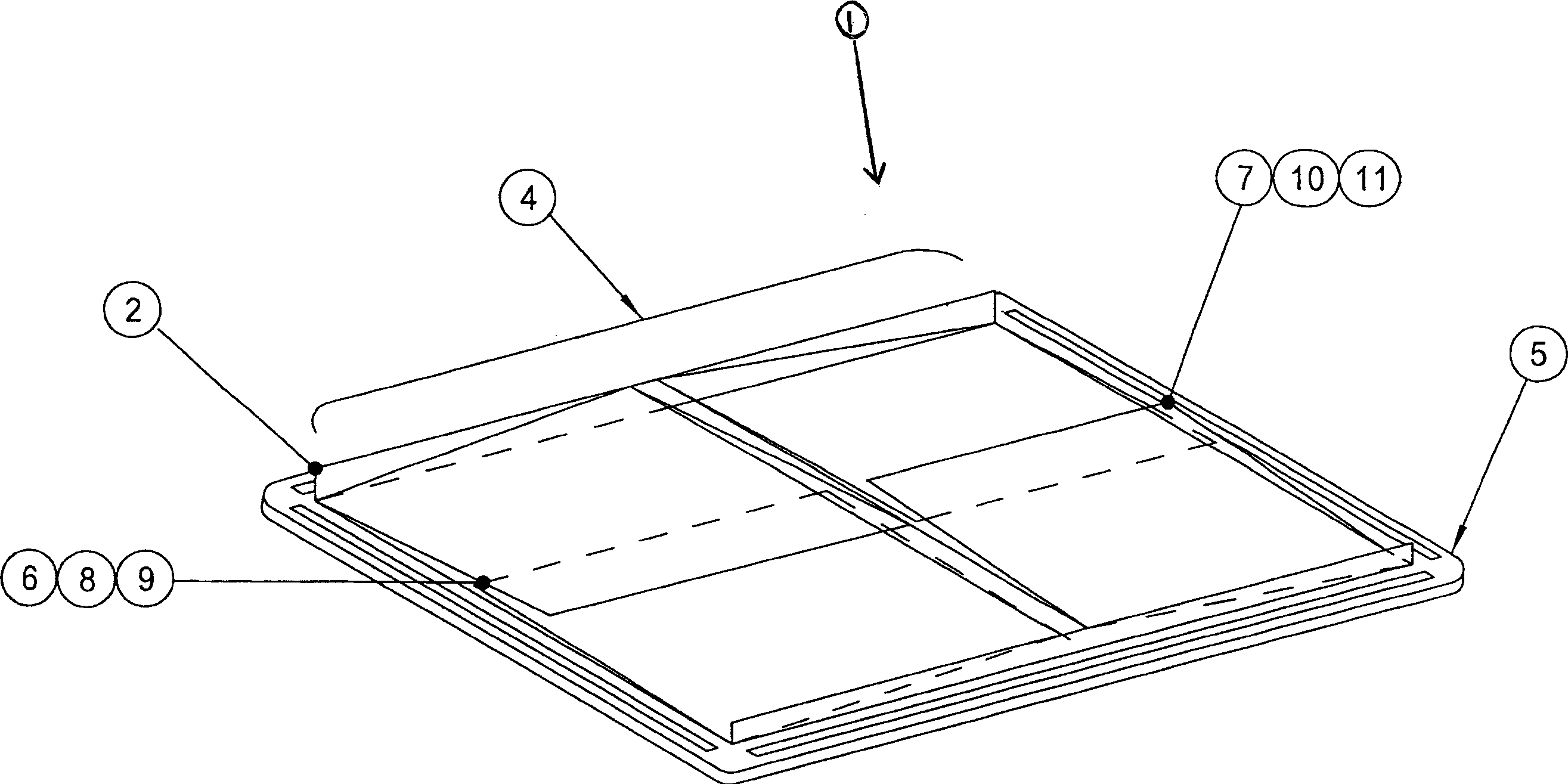

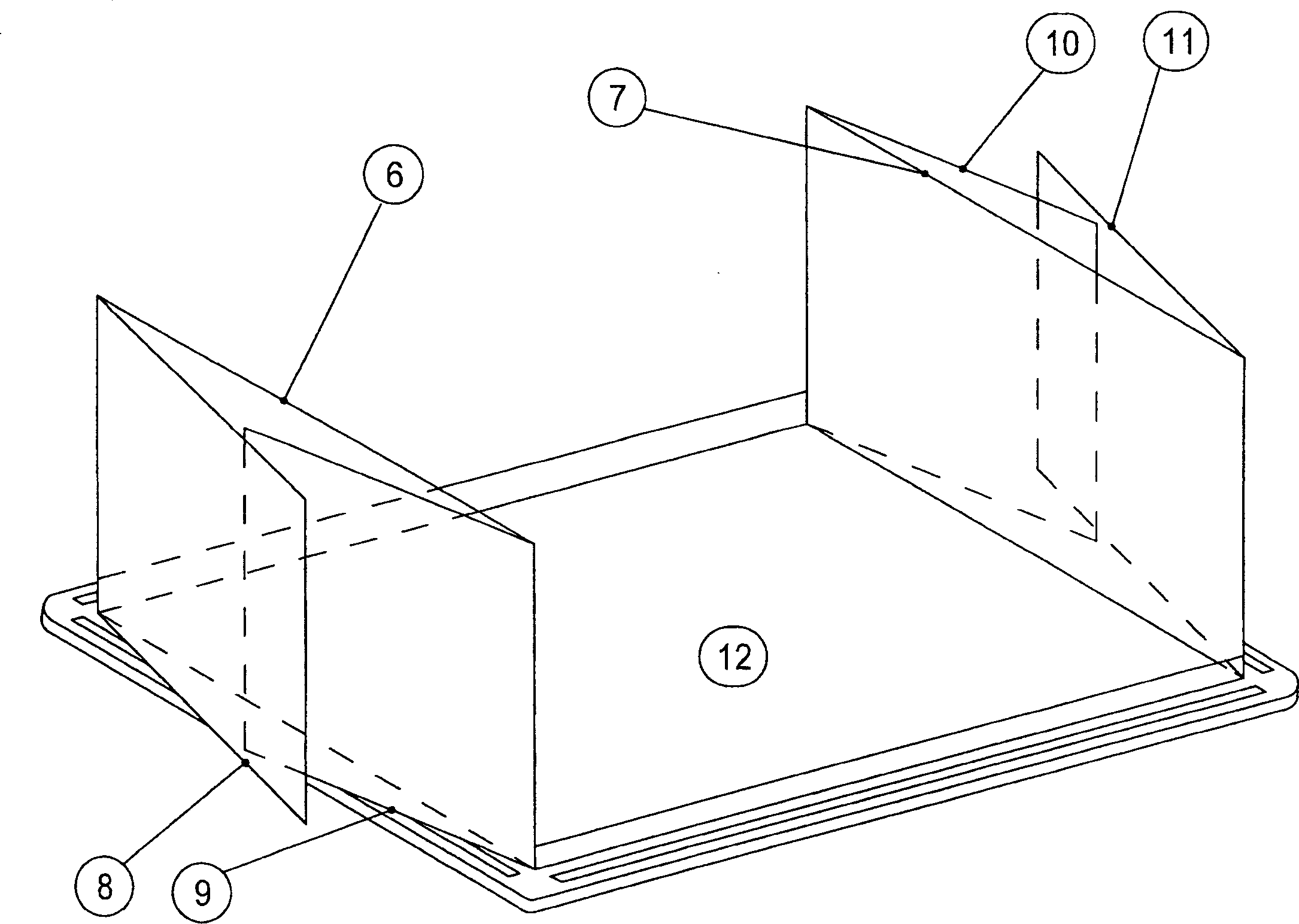

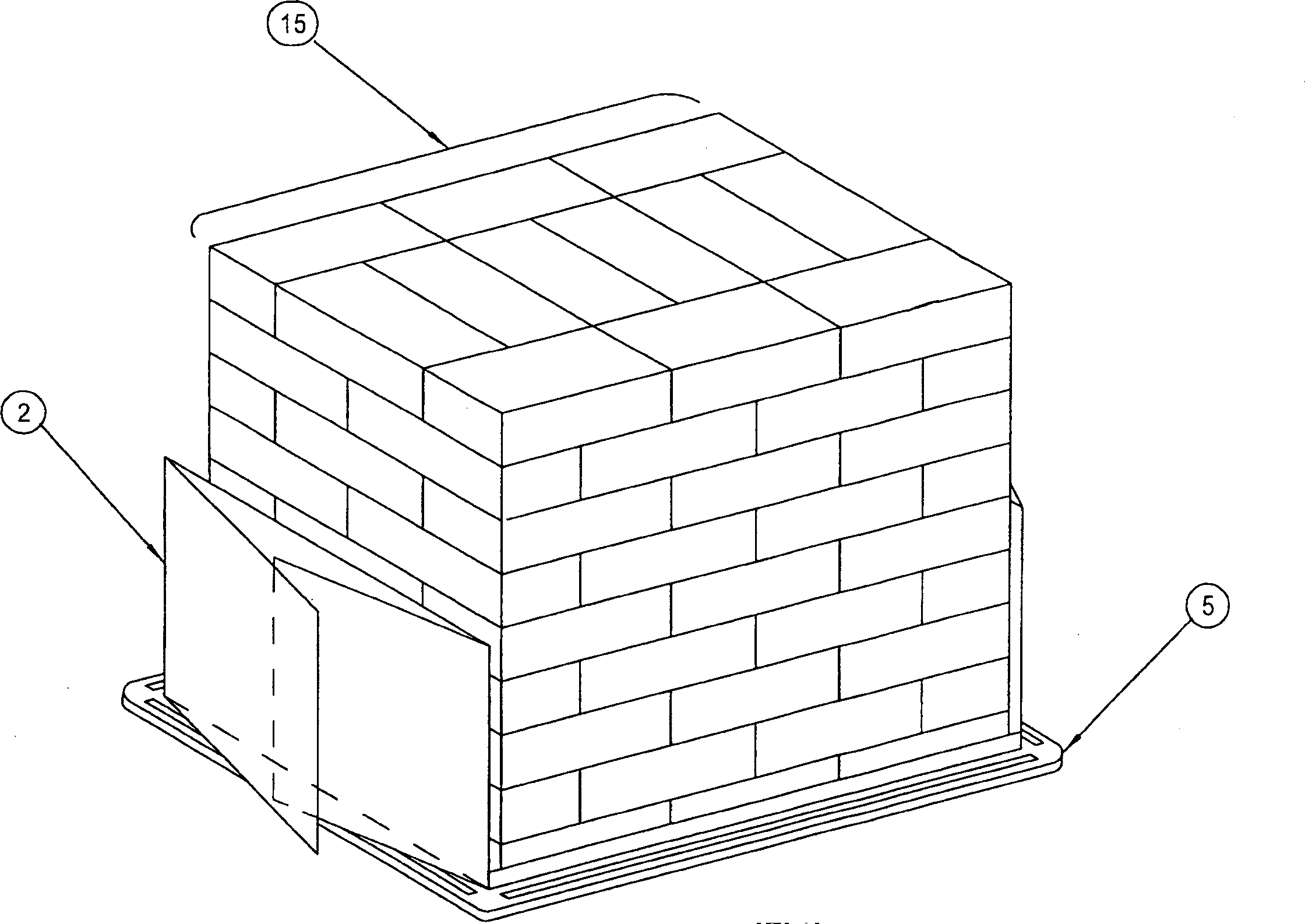

Device for transporting goods

InactiveCN1778641AGuaranteed overlapFully protectedShock-sensitive articlesContainers preventing decayPallet

Owner:AMSAFE BRIDPORT LTD

Large-particle-size coal gangue classifying and recycling device for tailings treatment

The invention discloses a large-particle-size coal gangue classifying and recycling device for tailings treatment. The large-particle-size coal gangue classifying and recycling device for tailings treatment comprises an anti-overlapping conveying device, a sorting and conveying device, a colorimeter screening device and a guiding plate device, wherein the anti-overlapping conveying device comprises a first conveying rack and a first conveyer belt assembly arranged on the first conveying rack; at least one group of slice stopping assembly is arranged on the first conveying rack; the sorting andconveying device comprises a second conveying rack and a second conveyer belt assembly arranged on the second conveying rack; and at least one rolling shaft sorting assembly and the colorimeter screening device are sequentially arranged on the second conveying rack. The large-particle-size coal gangue classifying and recycling device for tailings treatment provided by the invention is reasonablein structure arrangement, capable of colliding coal gangue or coal briquettes, avoiding the coal gangue or the coal briquettes from adhering and overlapping, ensuring that the coal briquettes can be effectively separated from the coal gangue, sorting and detecting the separated coal gangue or coal briquettes, and separately collecting the coal gangue and the coal briquettes according to the detection result, and high-efficiency and convenient in collection operation.

Owner:宋宏亮

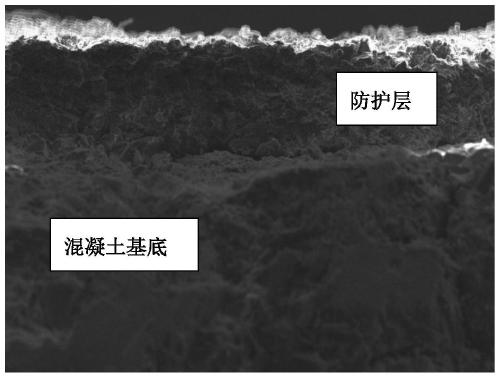

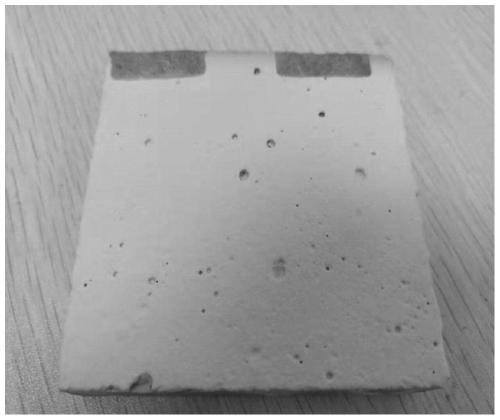

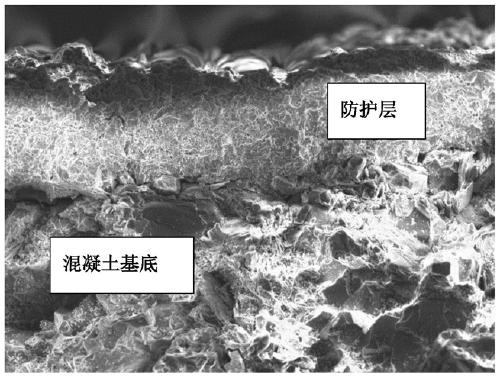

Concrete surface protection treatment method based on plasma hot-spraying technology

ActiveCN111575630AImprove frost resistanceImprove impermeability and durabilityMolten spray coatingWeather resistanceInorganic materials

The invention provides a concrete surface protection treatment method based on a plasma hot-spraying technology. According to the treatment method, firstly, high-pressure air at the temperature of 80DEG C to 100 DEG C is utilized to dry the surface of concrete; next, the high-pressure air is utilized to wrap and carry particles to roughen the surface of the concrete; then, high-pressure air at the temperature of 100 DEG C to 150 DEG C is utilized to flush and preheat the surface of the concrete; and finally, by the aid of plasma hot-spray equipment, a powdery inorganic non-metallic raw material with the particle size of 20 microns to 120 microns is used for hot-spraying an inorganic material protection layer on the surface of the concrete by adjusting the powder feeding rate, plasma power, the airflow rate, the moving velocity, the spraying distance and other parameters. Through the treatment method, the anti-freezing and anti-permeating abilities of the concrete are improved, the defects of poor weather fastness and short service life in traditional organic material protection coating brushing are overcome, and the method can be widely applied to surface protection on concrete prefabricated parts and cast-in-place concrete structures.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

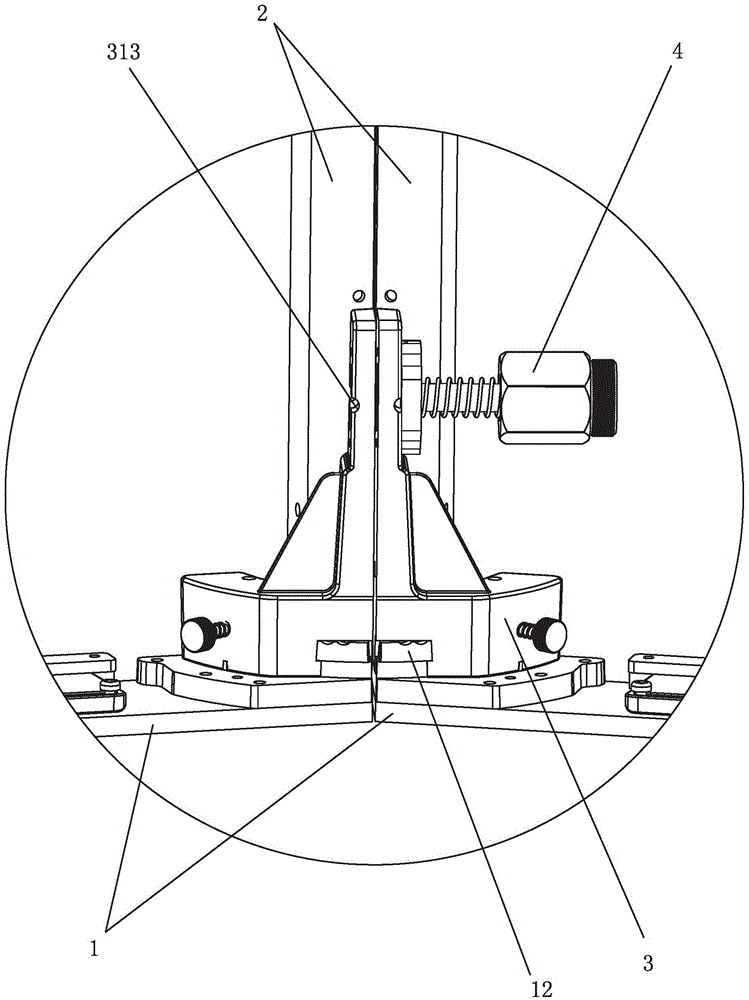

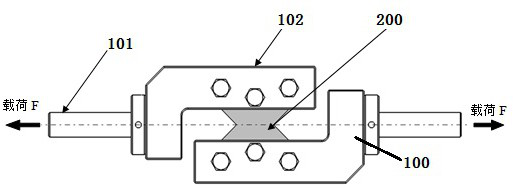

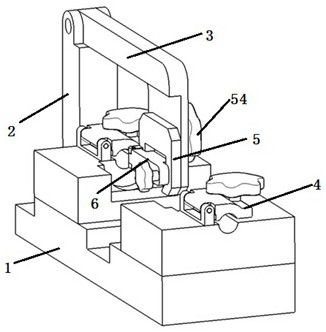

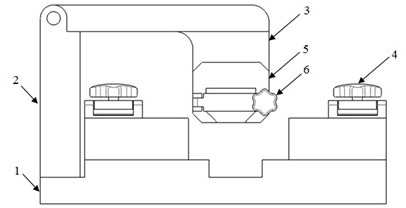

Auxiliary centering installation device for composite material track shear test

ActiveCN112067433AGuaranteed overlapEasy alignmentMaterial strength using steady shearing forcesEngineeringMachine

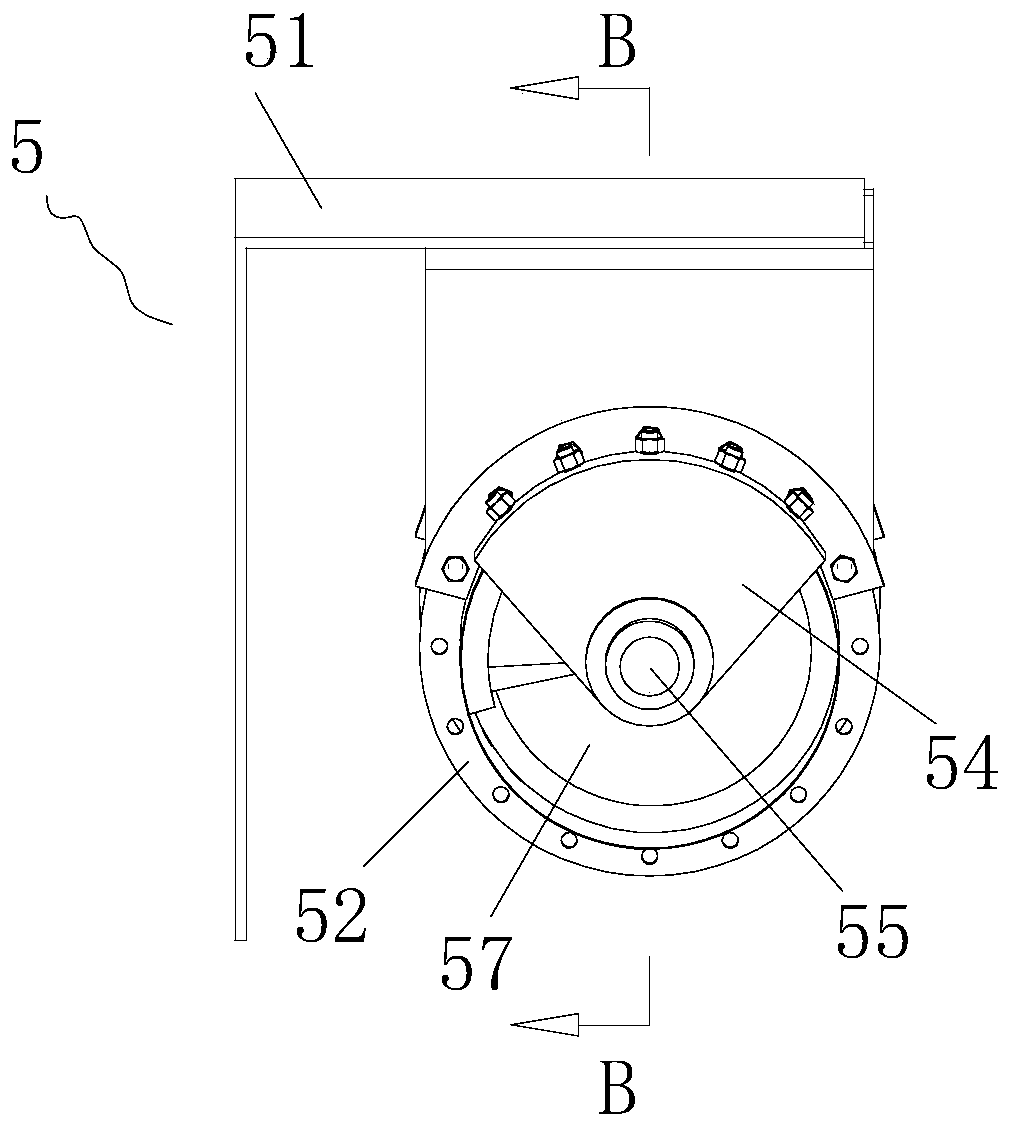

The invention belongs to the field of material performance testing, and relates to an auxiliary centering installation device for a composite material track shear test. The device comprises a base (1), a rotating rod (3) and a V-shaped groove plate (5), wherein two coaxial mounting holes (41) and a loading rod for fixing a test fixture are arranged on the base (1); the rotating rod (3) is of a rotatable structure, the tail end of the rotating rod (3) is provided with a V-shaped groove plate (5), the V-shaped groove plate (5) comprises two clamping jaws (52), the clamping jaws (52) just extendinto a V-shaped notch of a test piece, the connecting line of the two clamping jaws coincides with the axis of the mounting hole (41), and therefore the test piece coincides with the test fixture. Centering installation of the test fixture and the test piece can be conveniently achieved, it is guaranteed that the central axis of the V-shaped notch part of the test piece coincides with the loadingaxis of the testing machine, the centering performance of installation of the test fixture and the test piece is improved, personal errors are reduced, and the test result precision is improved.

Owner:CHINA AIRPLANT STRENGTH RES INST

Flat Bed Tarping System

InactiveUS20160089964A1Easily removeEasy to disassembleRemovable external protective coveringsLoad securingEngineeringTextile

A tarpaulin or tarping system for covering loads on flatbed trailers. Said tarping system includes retractable tarps of various lengths, for instance, 5 ft., 10 ft., or 20 ft. lengths that are affixed to the cut-outs of the flatbed and then stretched across the load. These tarps can be placed adjacent to each other along the length of the flatbed, or placed on opposing sides of the flatbed, or placed across the width of the flatbed to ensure maximum overlap of the tarps and full coverage of the load.

Owner:RETTIG ALAN

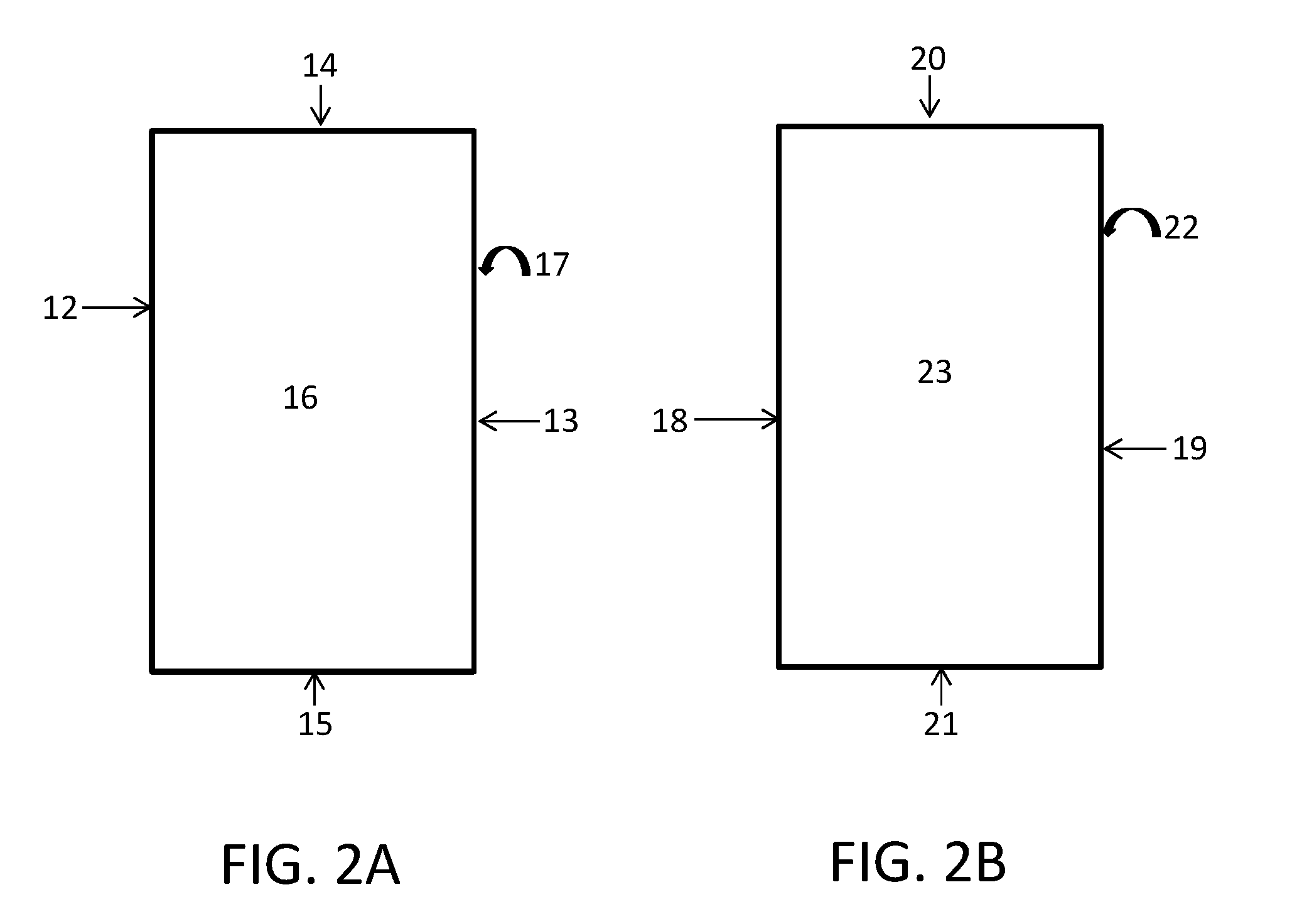

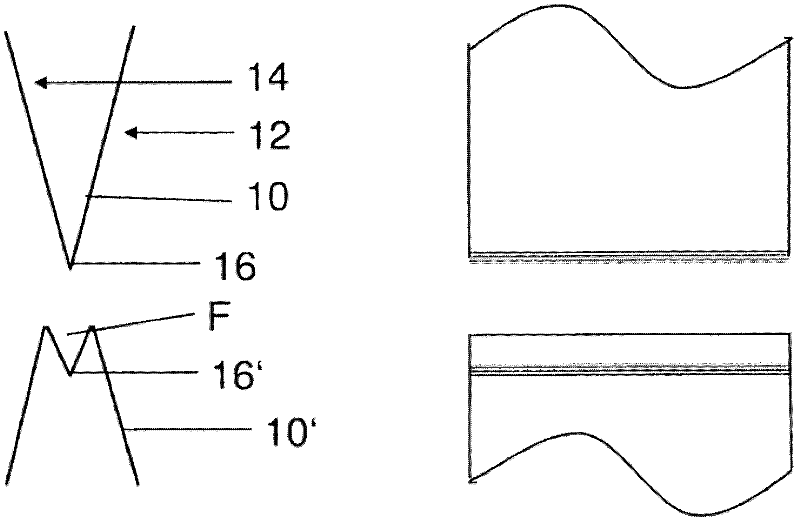

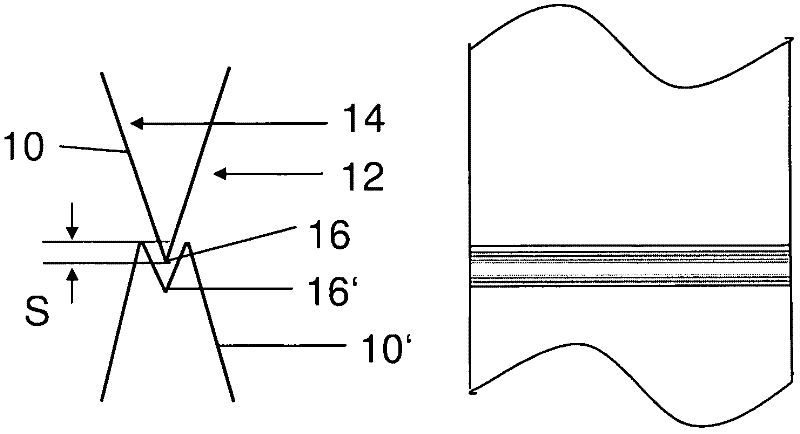

Method for the environmentally sealed connection of two at least partially flexible packages

InactiveCN102448836AGuaranteed overlapFlexible bulk container emptying systemsSolid materialEngineeringMechanical engineering

The invention relates to a method for contamination-free docking of a first at least partially flexible package (10) to a second at least partially flexible package (10'). The packages (10, 10') consist of films, at least in part, having outer sides (12) that can be solidly welded, and inner sides (14) can be detachably welded. According to the invention, a solid connection between the packages is produced outside the detachably welded inner sides in order to create a channel between the packages. The channel is opened by loosening the connection between the inner sides.

Owner:FLECOTEC

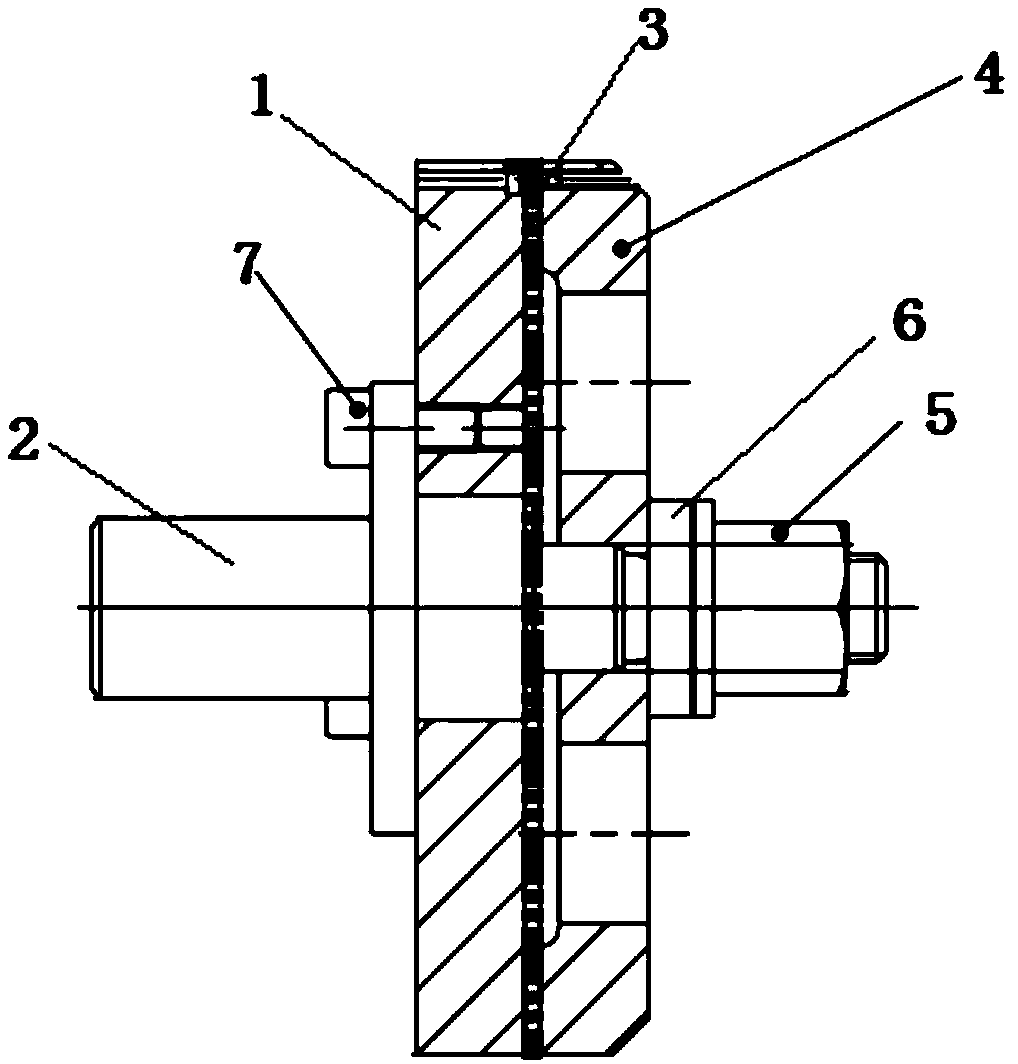

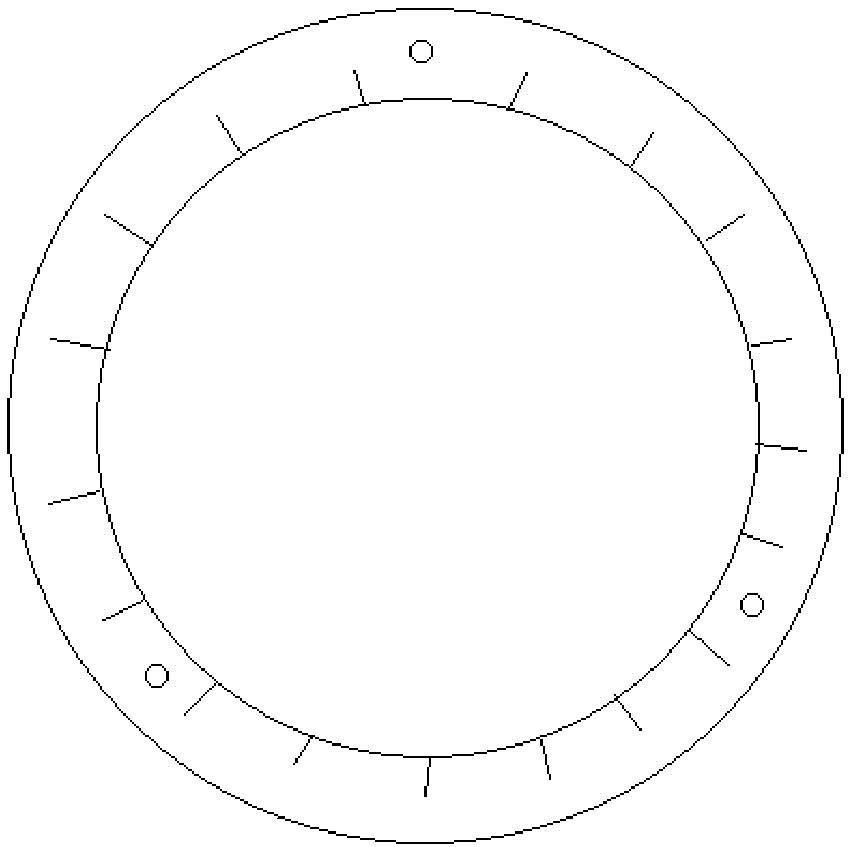

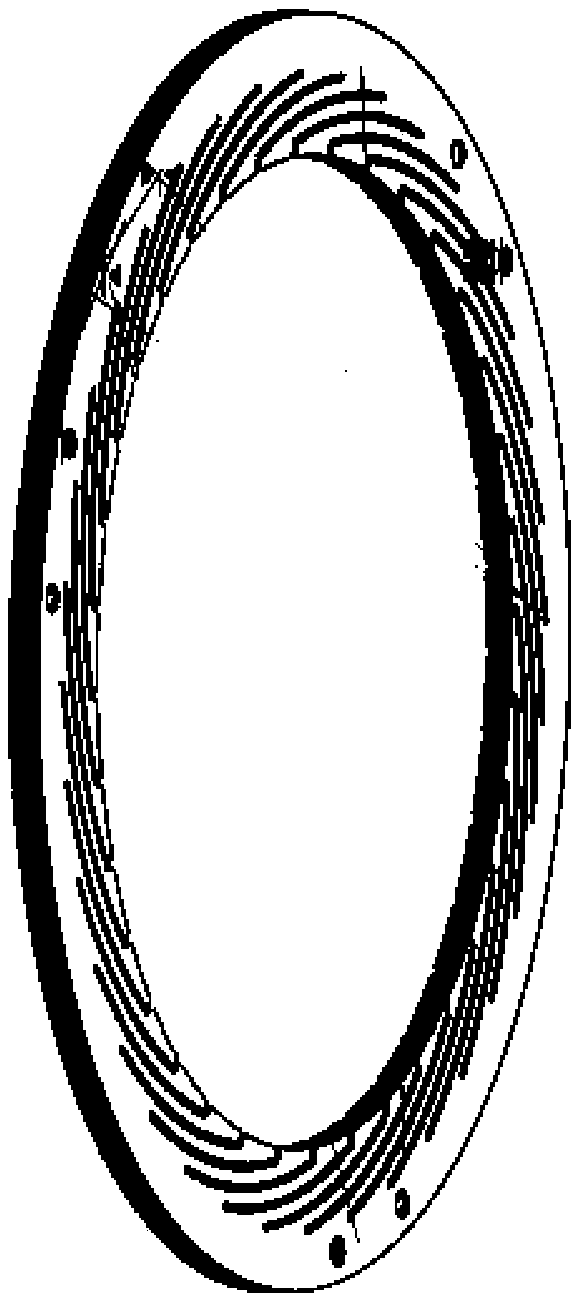

Laser circumferential seam welding fixture for multilayer thin-walled annular parts and method

ActiveCN107552982AAvoid Solder StickingImprove thermal conductivityWelding/cutting auxillary devicesAuxillary welding devicesChromium coatingWeld seam

The invention discloses a laser circumferential seam welding fixture for multilayer thin-walled annular parts and a method. To-be-welded multilayer thin-walled annular parts are clamped through a positioning disc and a pressing disc, and the external diameters of single layer thin-walled annular parts are greater than the external diameters of the positioning disc and the pressing disc, so that welding adhesion between the thin-walled annular parts and the positioning disc and the pressing disc is avoided; both the positioning disc and the pressing disc are made of red copper T2 material and are subjected to chrome-faced treatment; the excellent thermal conductivity and heat dissipation of the red copper are utilized so that welding deformation can be effectively prevented in the laser circumferential seam welding process of the multilayer thin-walled annular parts; non-adhesion during welding of a chromium coating and high-temperature materials are utilized so that welding adhesion between components and a fixture body can be effectively prevented, welding efficiency is greatly improved, and the qualified rate of product welding is ensured; in the welding process, the welding speed adopts the circumferential rotating speed being 0.95 r / min, the longitudinal feeding speed is 0.25 mm / r, and it can be ensured that a small section of welding seam is overlapped for each circumferential seam welding and the position of next circumferential seam welding is accurate.

Owner:AECC AVIATION POWER CO LTD

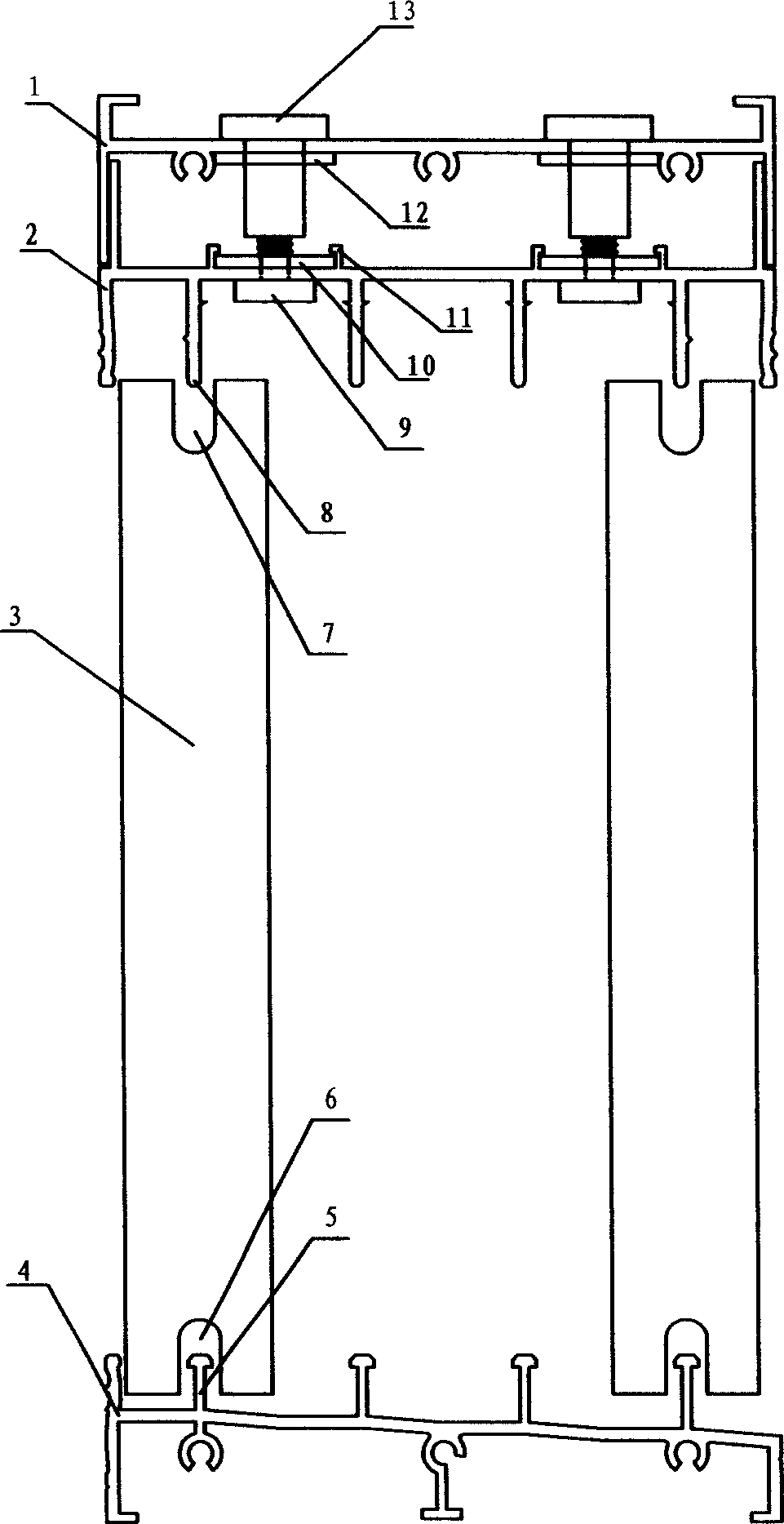

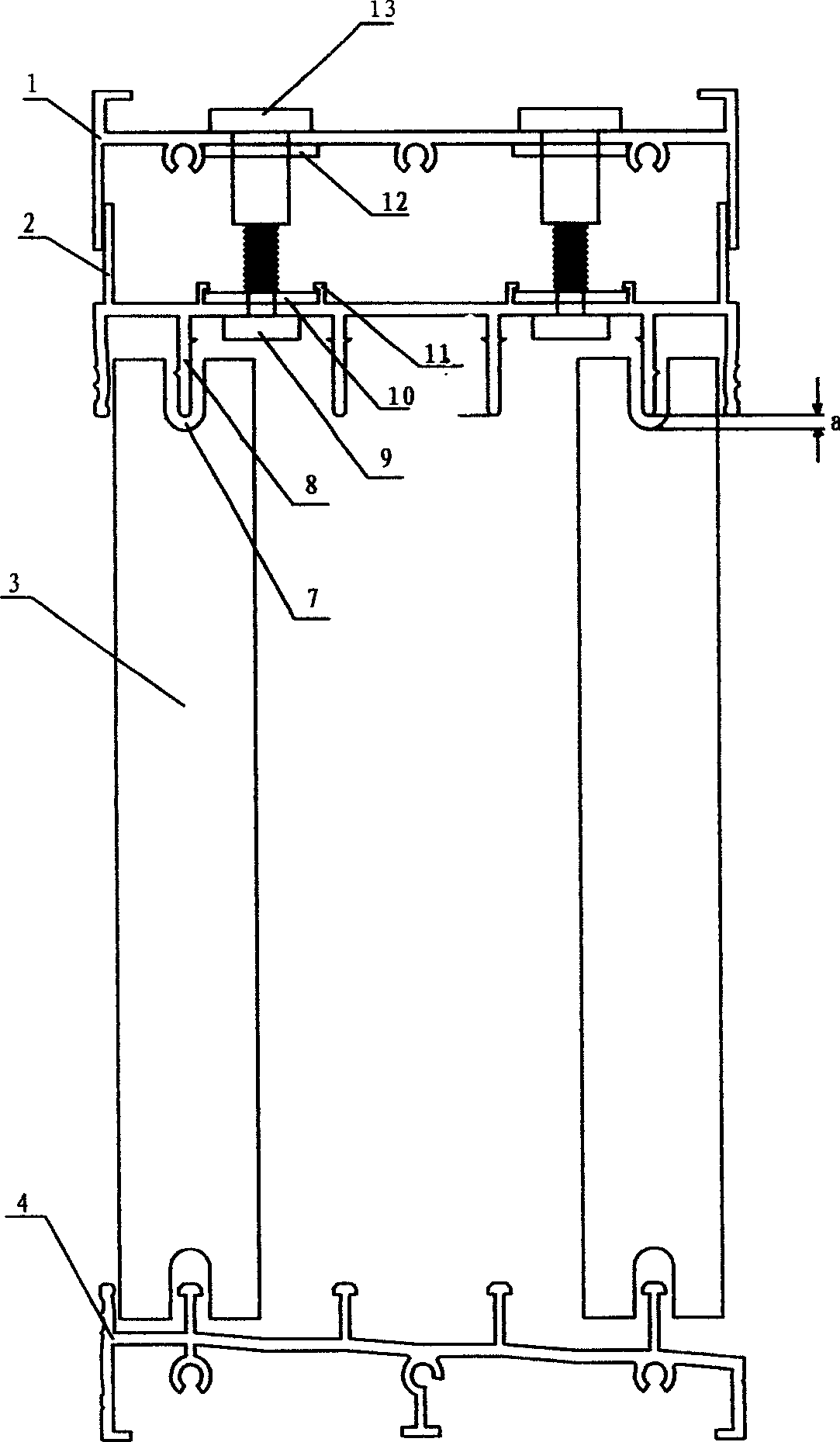

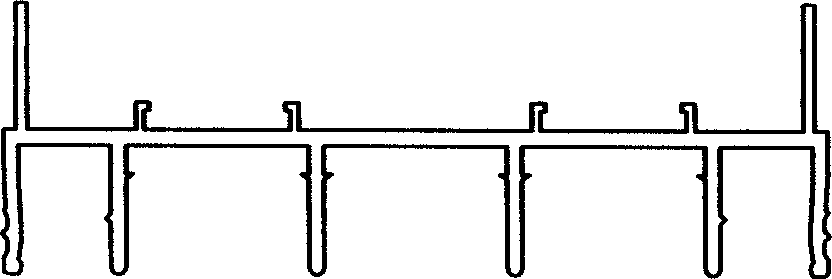

Sliding door and window with movable top slideway

InactiveCN1858391AMake up for the size error of blankingImprove anti-shedding effectWing arrangementsWing suspension devicesAir tightnessElectrical and Electronics engineering

Owner:FOSHAN FAMINJIA DOOR & WINDOW

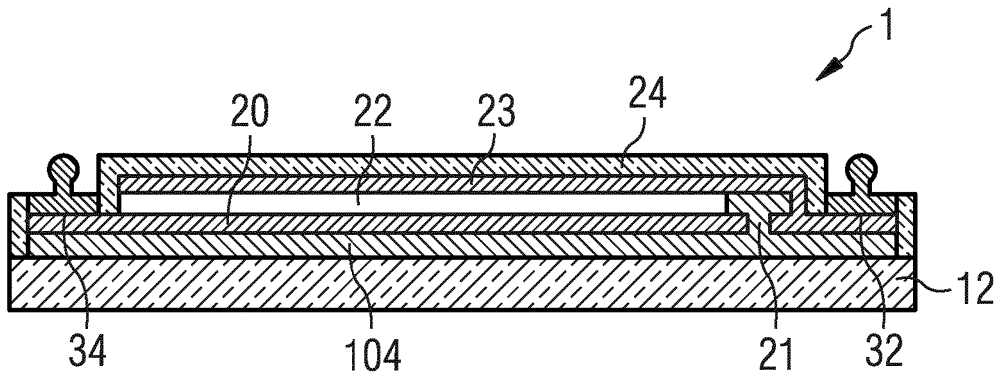

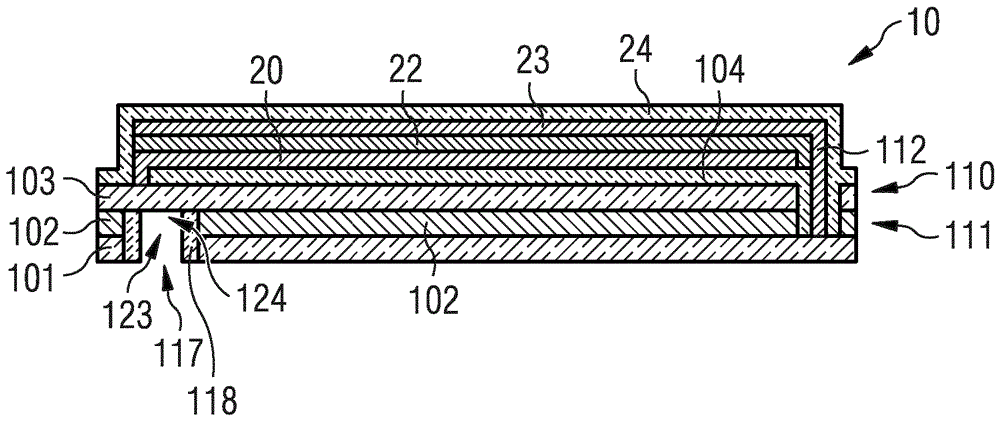

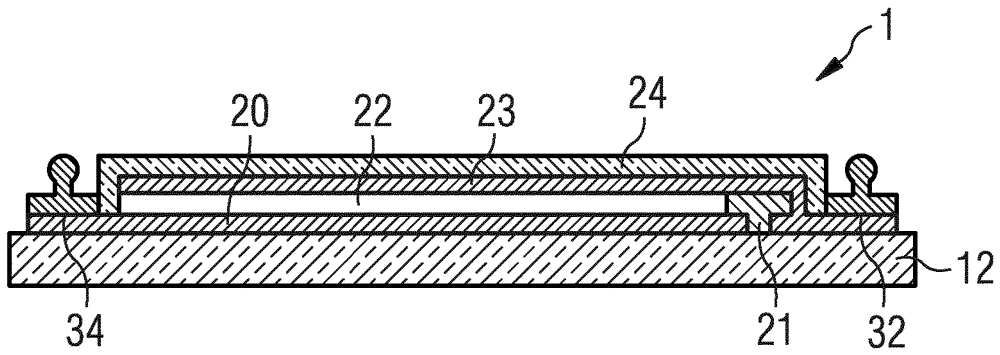

Optoelectronic component and method for producing same

ActiveCN106663744AReduce contact resistanceImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronElectrically conductive

An optoelectronic component (10) and a method for producing same are provided in various exemplary embodiments. The optoelectronic component (10) has a first electrically conductive contact layer (101), an electrically insulating layer (102) over the first electrically conductive contact layer (101), a second electrically conductive contact layer (103) over the electrically insulating layer (102), a first electrically conductive electrode layer (20) over the second electrically conductive contact layer (103), at least one optically functional layer structure (22) over the first electrically conductive electrode layer (20) and a second electrically conductive electrode layer (23) over the optically functional layer structure (22). The second electrically conductive contact layer (103) comprises a first recess (110). The electrically insulating layer (102) comprises a second recess (111) which overlaps the first recess (110). An electrically conductive through-contact (112) is arranged in the first recess (110) and in the second recess (111), said through-contact being guided to the first electrically conductive contact layer (101). The electrically conductive through-contact (112) is electrically insulated with respect to the second electrically conductive contact layer (103).

Owner:OSRAM OLED

Chimney tube ash-removing device

The invention relates to the technical field of chimney tube ash-removing, and discloses a chimney tube ash-removing device. The device comprises a machine body, a circular mounting groove is formed in the left side of the top surface of the machine body, a positioning bearing is fixedly connected to the inner side wall of the circular mounting groove, a rotary positioning mechanism is fixedly inserted into the inner side wall of the shaft side inner ring of the positioning bearing, and the part, located above the top of the machine body, of the rotary positioning mechanism is connected with adriven rotary wheel in a sleeved mode; and the right side of the bottom surface of the machine body is fixedly connected with a low-speed motor through a bolt, an output shaft of the low-speed motorpenetrates through the bottom surface of the machine body to extend to the upper part of the machine body, the tail end of the low-speed motor is fixedly connected with a driving rotary wheel, and a connecting belt is in transmission connection between the driving rotary wheel and the driven rotary wheel. According to the chimney tube ash-removing device, the removing speed of chimney tube inner side wall ash is accelerated, therefore the purpose of changing the acting friction force between an ash-removing brush and a chimney tube is achieved, and the ash attached to the inner side wall of the chimney tube can be brushed away more effectively.

Owner:日照新睿招商发展有限公司

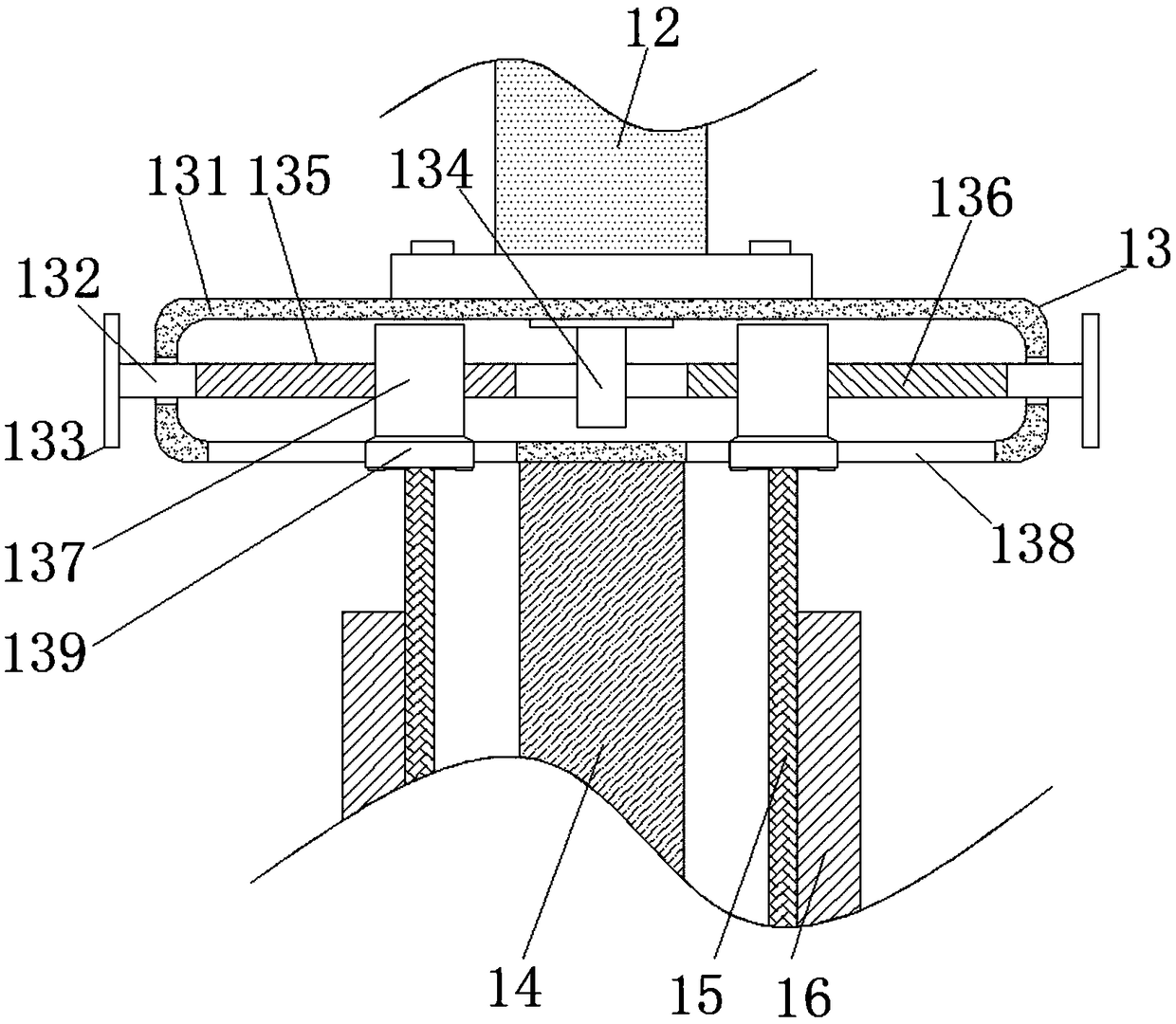

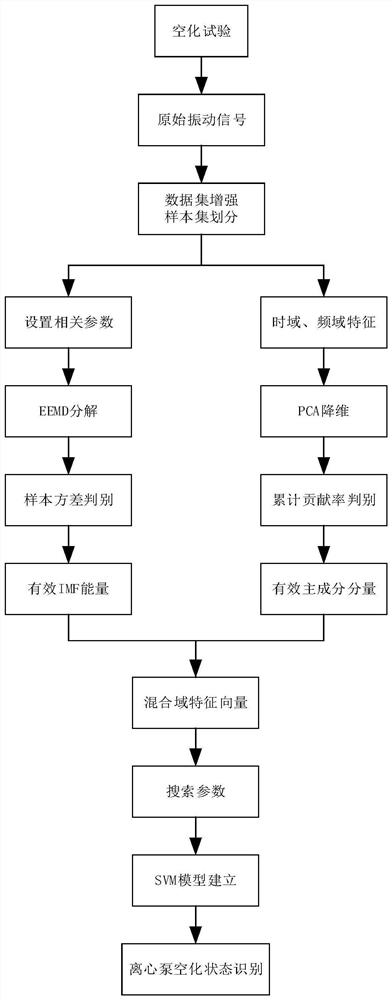

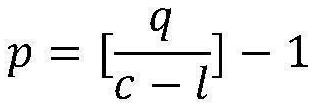

Centrifugal pump cavitation state identification method

PendingCN114548272AAvoid loss of feature informationReduce data redundancySubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionCentrifugal pumpEngineering

The invention discloses a centrifugal pump cavitation state identification method, which comprises the following steps of: taking vibration signals in different cavitation states as original data, decomposing the vibration signals by using ensemble empirical mode decomposition, calculating the energy of each IMF component, and calculating the variance value of the energy of the same-order IMF component in different cavitation states; effective IMF energy is selected according to the variance value to serve as a main feature vector; extracting a time domain feature and a frequency domain feature of the centrifugal pump vibration signal to form a composite feature vector, and then performing dimensionality reduction on the composite feature vector to obtain an auxiliary feature vector; and combining the main feature vector and the auxiliary feature vector to construct a mixed domain feature vector, inputting the mixed domain feature vector into a support vector machine for data training and verification, and finally realizing centrifugal pump cavitation state recognition. The method can improve the cavitation recognition accuracy of the centrifugal pump.

Owner:CHINA JILIANG UNIV

Fire clay blasting preventing baking method of steel ladle mechanism

InactiveCN105081303APrevent the danger of steel channelingEasy to fixMelt-holding vesselsMining engineeringCombustible gas

A fire clay blasting preventing baking method of a steel ladle mechanism comprises the steps that the cool state steel ladle mechanism with a replaced water gap and a replaced sliding plate is placed above an adjustable nozzle type baker, wherein the adjustable nozzle type baker comprises an outer cylinder, a gas pipe is arranged in the outer cylinder, and a gas pipe fixing and height adjusting mechanism is arranged on the side wall of the outer cylinder; the height of the gas pipe is adjusted, the combining face of the upper water gap and the upper sliding plate in the steel ladle mechanism is located in a nozzle combusting gas flame high-temperature area, and gas flowing out of a nozzle is ignited for baking; during baking, the combustible gas flow sequentially becomes high, low and high, and the gas supply time of the high-flow combustible gas is 2-3 times of the gas supply time of the low-flow combustible gas; and the total baking time is controlled within 30-60 min, an organic bonding agent and water in fire clay used for sealing of the sliding plate in the steel ladle mechanism are decomposed and volatilized step by step, and the fire clay is molded and stabilized. The organic bonding agent and the water in the fire clay used for sealing of the sliding plate can be decomposed and volatilized step by step, and the safety hazard of steel fleeing caused by instant fire clay blasting during molten steel casting on is avoided.

Owner:SHANDONG IRON & STEEL CO LTD

Single-radio source-driven dual-acoustic optical filter component secondary acousto-optic filtering device and method

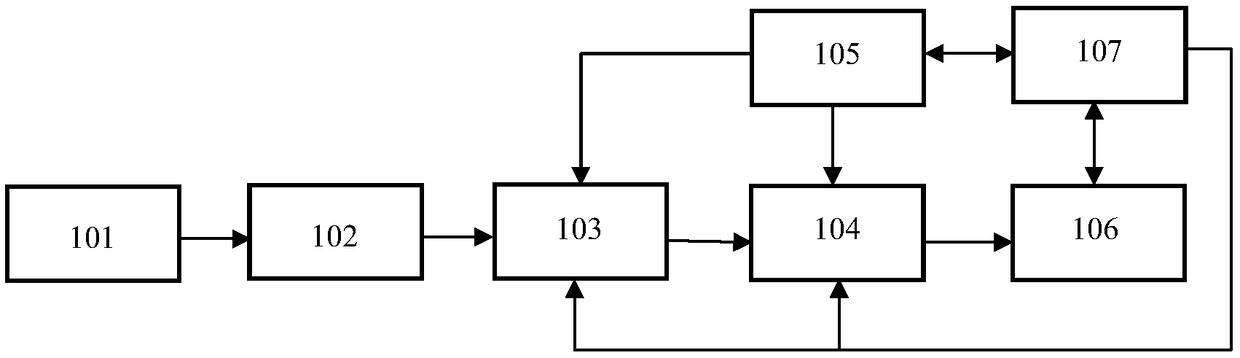

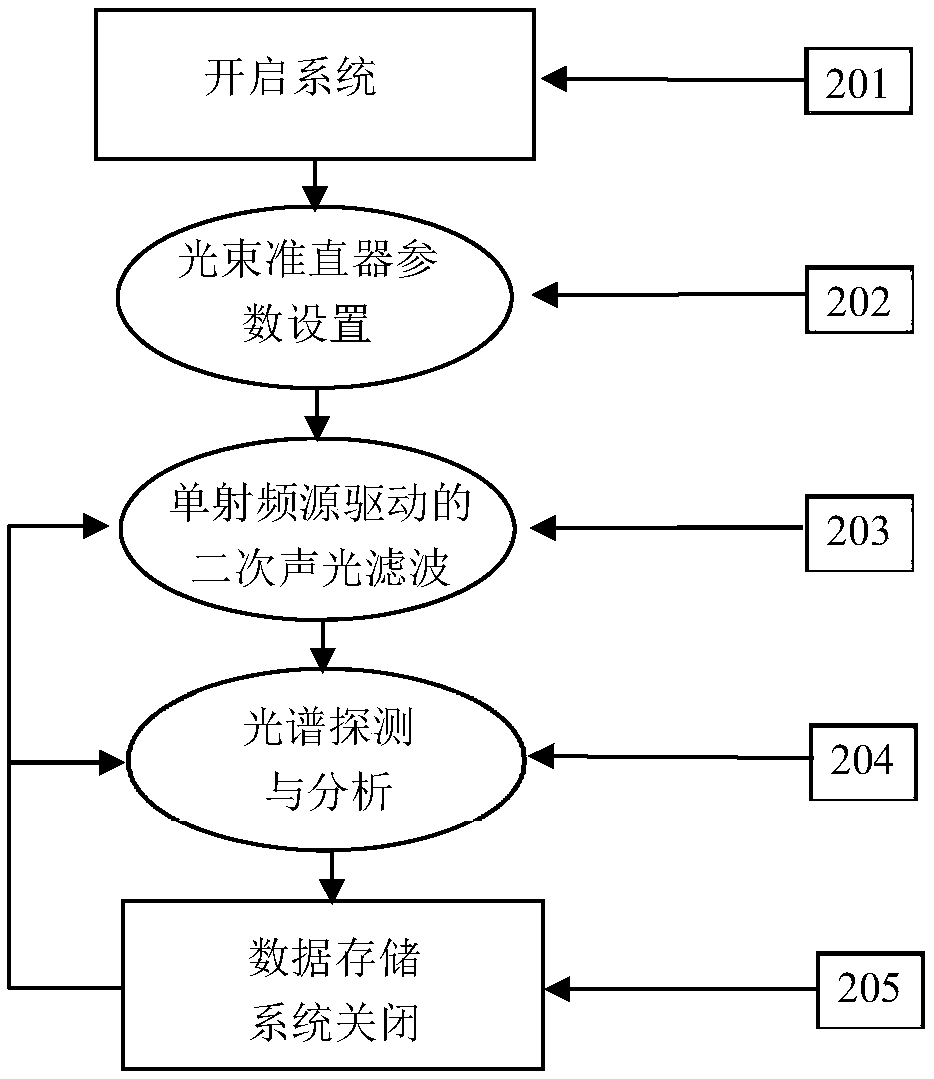

PendingCN109029729AEasy to fixOptimum Polar Angle of Incident LightRadiation pyrometrySpectrum investigationLight beamEngineering

The invention discloses a single-radio source-driven dual-acoustic optical filter component secondary acousto-optic filtering device and method. The single-radio source-driven dual-acoustic optical filter component secondary acousto-optic filtering device comprises a radio source, a computer, and a broadband light source, a beam collimator, a first acousto-optic filtering component, a second acousto-optic filtering component and a spectrum detector, which are orderly connected; the computer is connected with the first acousto-optic filtering component, the second acousto-optic filtering component, the radio source and the spectrum detector, respectively; the radio source is connected with the first acousto-optic filtering component and the second acousto-optic filtering component, respectively; the beam collimator converges and aligns the light of the broadband light source so as to form parallel light beams; the first acousto-optic filtering component performs first acousto-optic filtering on the parallel light beams; the second acousto-optic filtering component performs second acousto-optic filtering on the light beams subjected to first acousto-optic filtering; the light beams subjected to the second acousto-optic filtering are output to the spectrum detector; and the spectrum detector collects spectral information and outputs the spectral information to the computer. According to the single-radio source-driven dual-acoustic optical filter component secondary acousto-optic filtering device and method in the invention, the two acousto-optic filtering components can be simultaneously controlled through one radio source, thereby realizing twice acousto-optic filtering and improving the spectral resolution.

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com