Intelligent grinding device based on force control and visual technology

A visual technology, intelligent technology, applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the lack of interaction of the feeding system, the interactivity of feedback, the inability to deal with the complex situation of grinding and polishing, and the lack of control system and sensing system, to achieve the effect of improving the grinding surface effect, easy control, and uniform mass distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

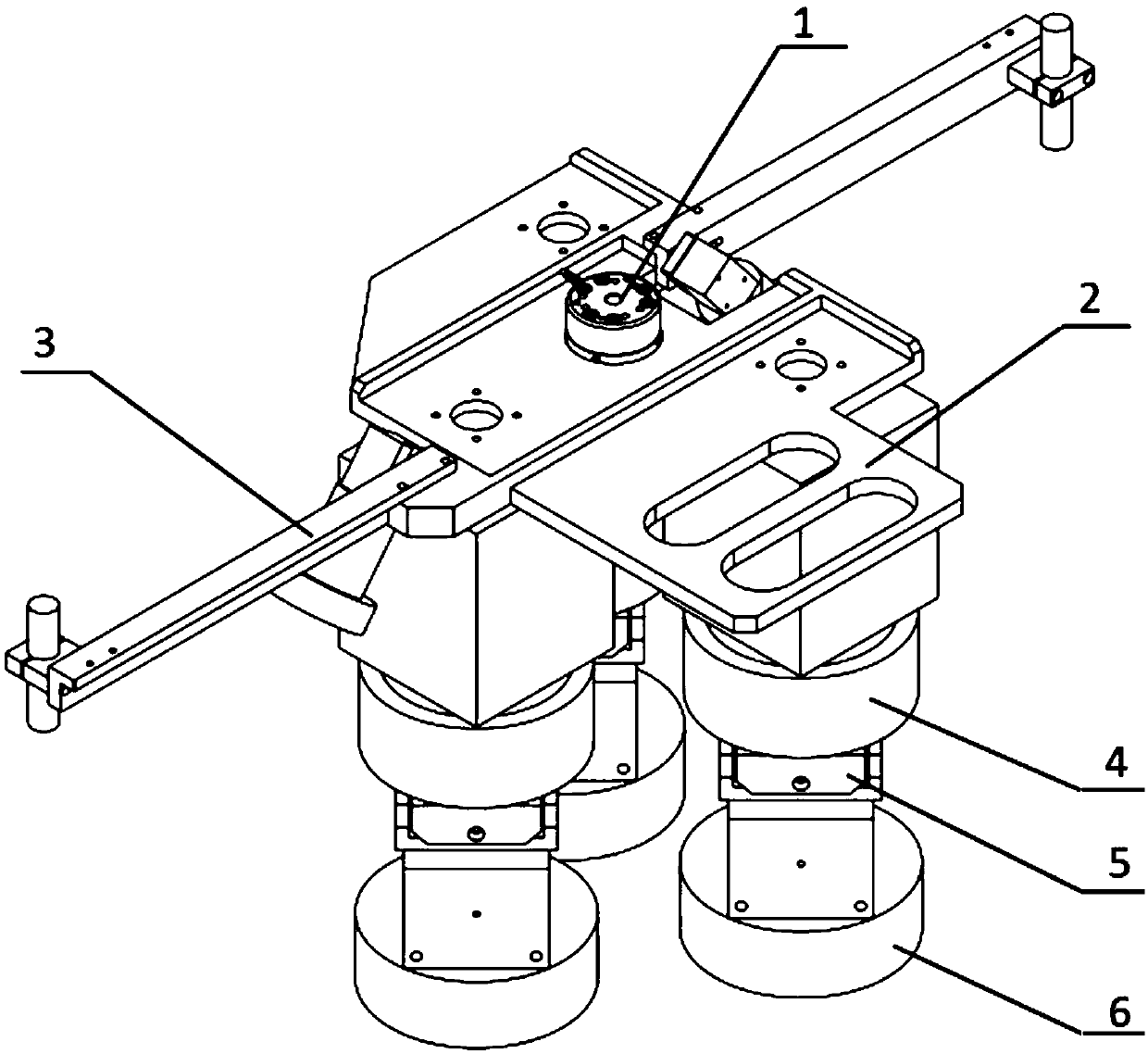

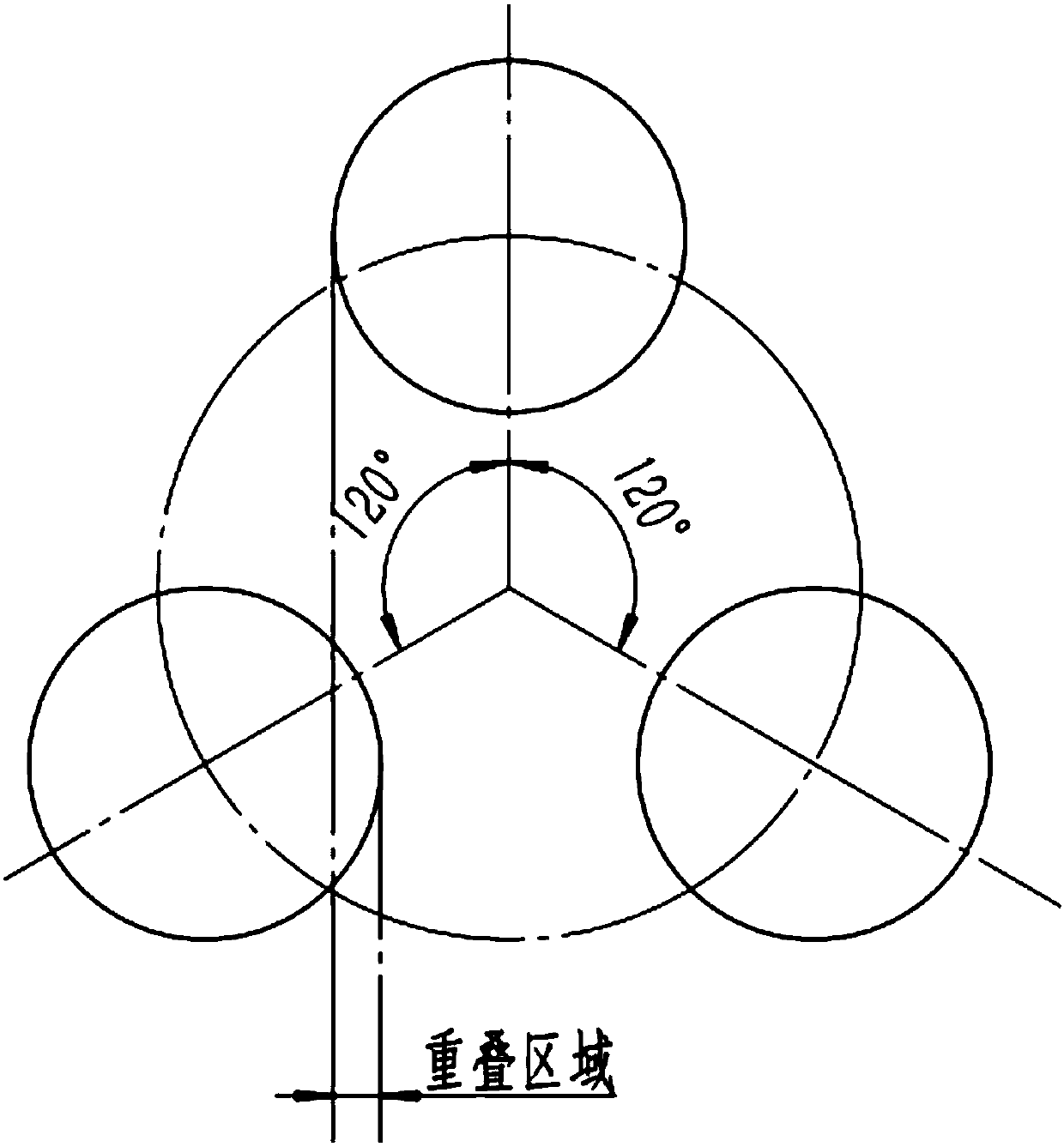

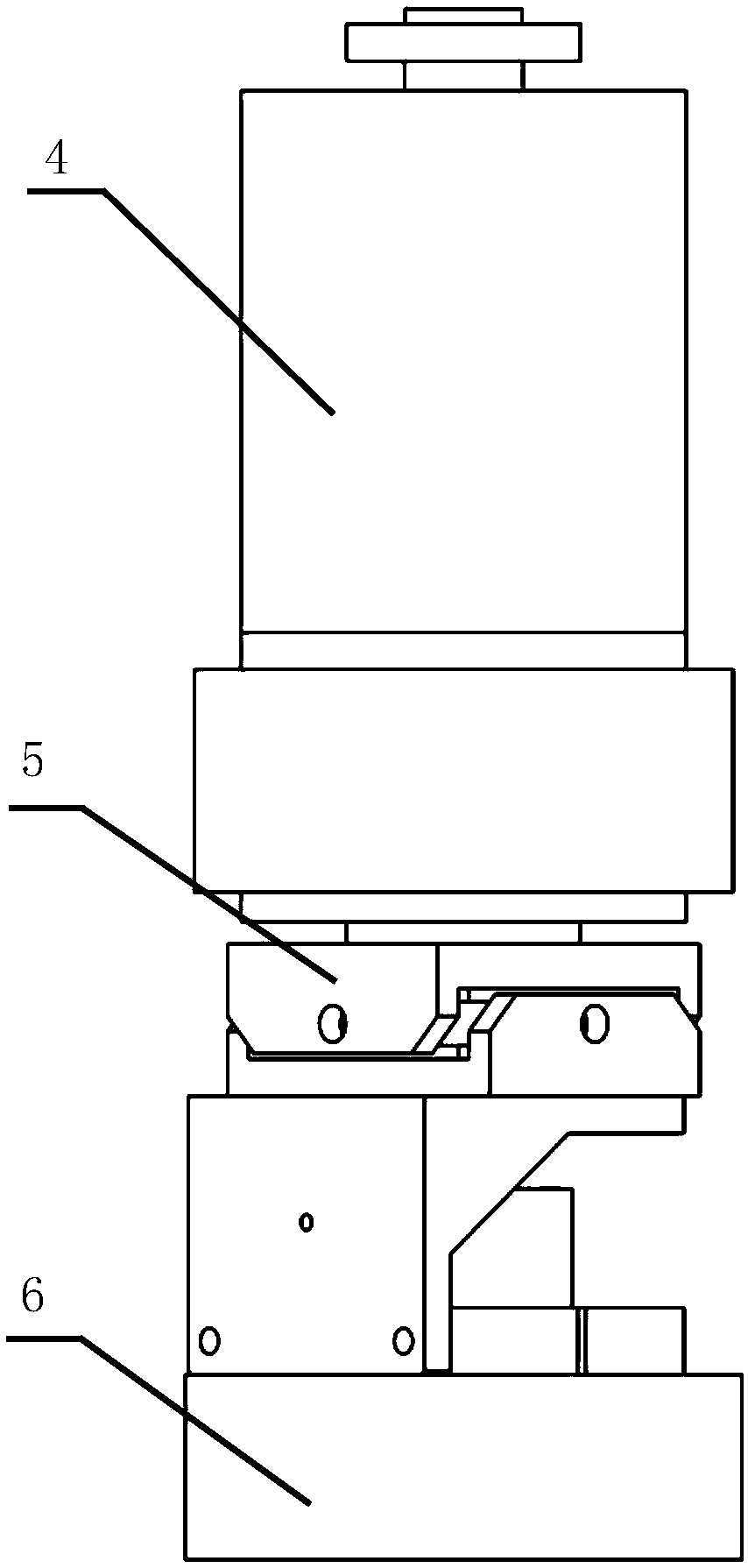

[0025] The present invention is an intelligent grinding device based on force control and vision technology, and its structure is as follows Figure 1-5 shown. The grinding device includes: a six-dimensional force sensor 1, an industrial vision component 3, a constant force actuator 4, a passive adjustment device 5, a connecting piece 2 and a grinding head 6 with a sponge pad. The six-dimensional force sensor is fixed on the connector, and the six-dimensional force sensor can detect the force value in all directions in space, that is, F X , F Y , F Z , T X , T Y , T Z , During the grinding process, the interference of gravity and other factors should be eliminated, and the force in all directions should be kept uniform. The six-dimensional force sensor guides the feeding system (such as joint robots, CNC machine tools, etc.), and adjusts the grinding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com