Automatic pasting robot system for rocket engine fuel storage box heat insulation layer

A technology of rocket engine and robot system, which is applied in the field of robot system for automatic pasting of thermal insulation layer of rocket engine fuel storage tank, to achieve the effects of avoiding high-intensity labor, improving consistency, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings, and it is stated here that the present invention is explained with the exemplary embodiment, but not as a limitation of the present invention.

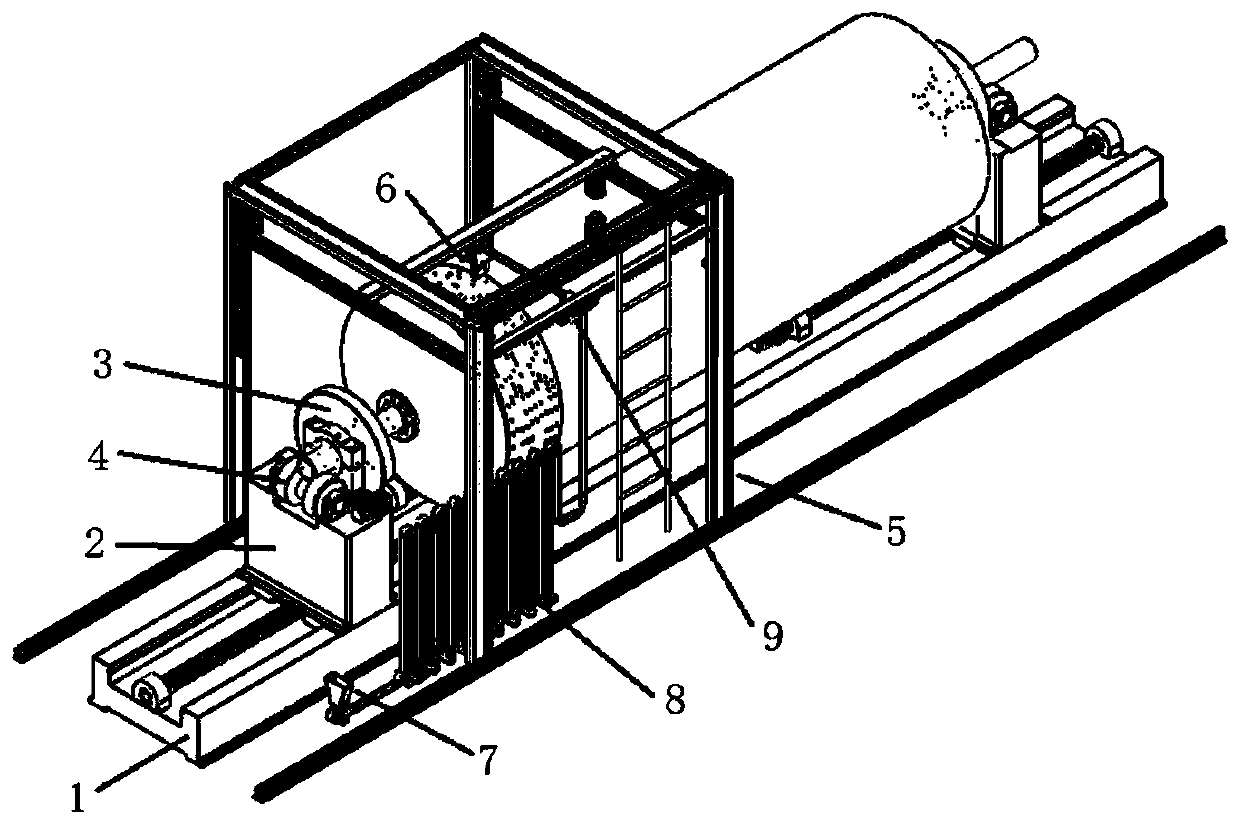

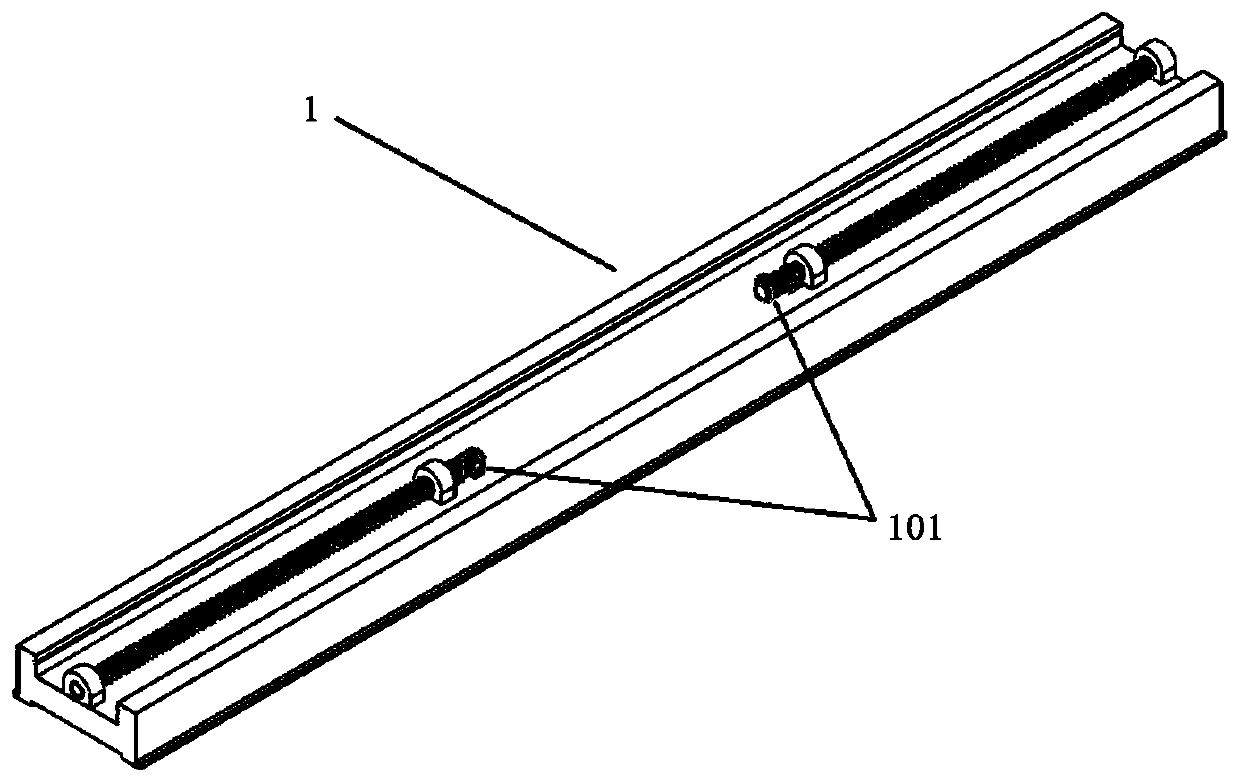

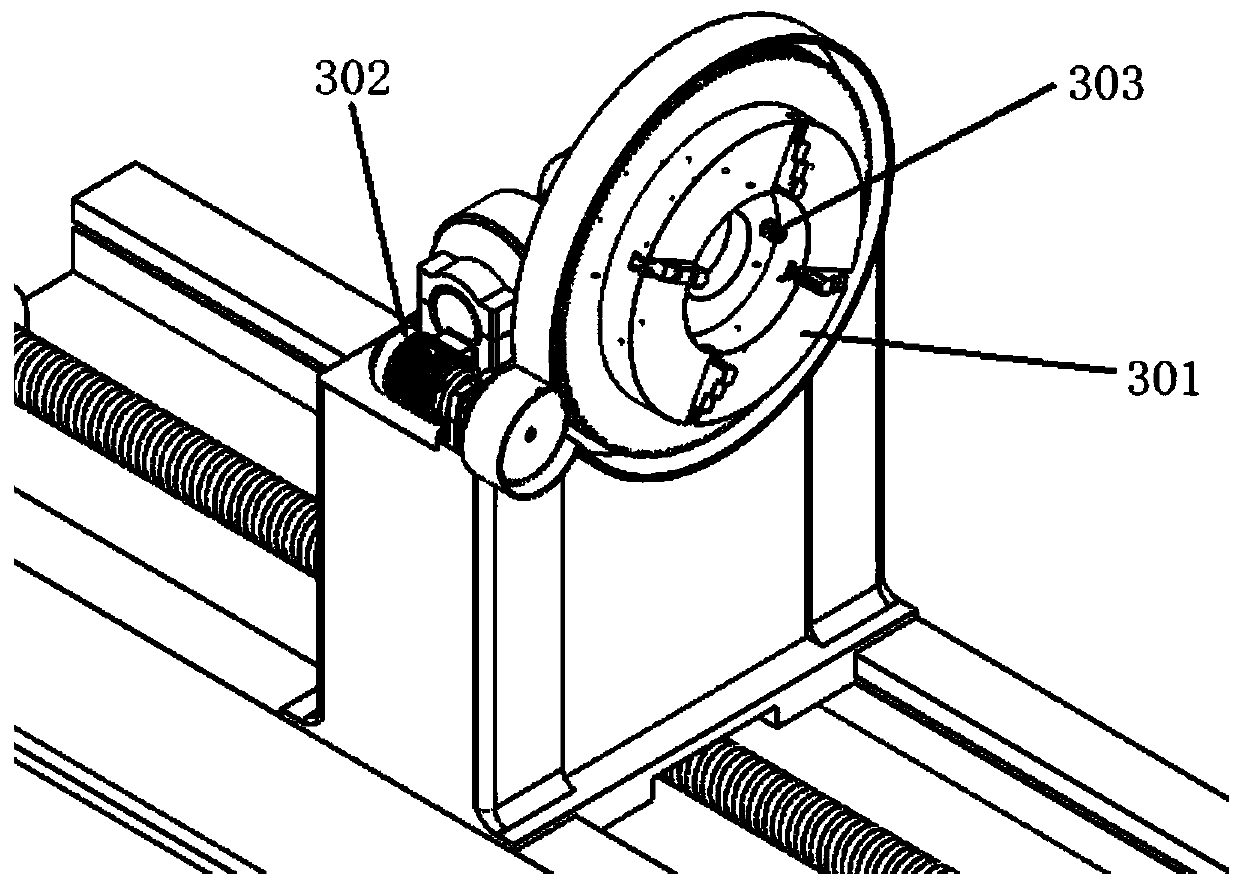

[0050] see figure 1 and figure 2 , a robot system for automatically adhering the thermal insulation layer of a rocket engine fuel storage tank proposed by the present invention, comprising a frame 1 fixedly connected to the ground, a support platform 2 installed on the frame 1, and a rocket storage tank installed on the support platform 2 End cover clamping and rotating mechanism 3 and height adjustment mechanism 4, gantry and guide rail 5 fixed on the ground, composite manipulator 6 for pasting on the gantry and guide rail 5, gluing mechanism 7, drying mechanism 8, strip separation Institution 9. The frame 1 is installed on the ground, forms a sliding pair with the two support platforms 2, and is powered by the driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com