Belt type grinding machine head

A technology of machine head and machine head frame, which is applied in the direction of abrasive belt grinder, grinding machine, grinding/polishing equipment, etc., and can solve the problems of reduced efficiency and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

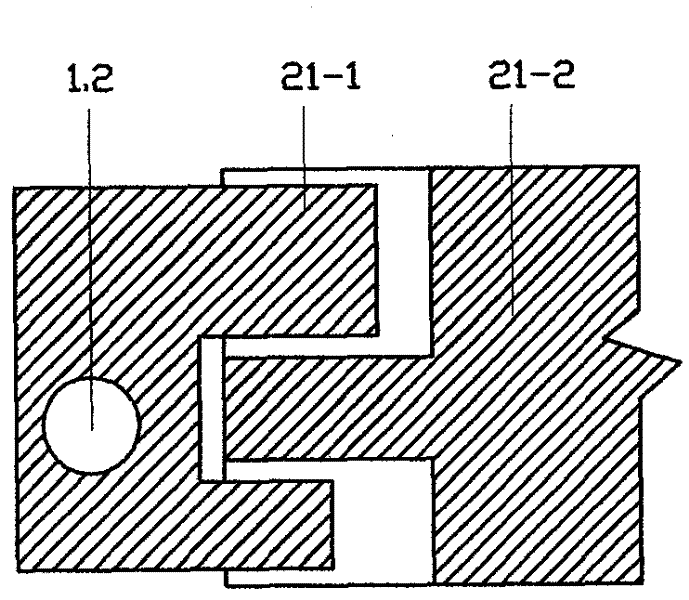

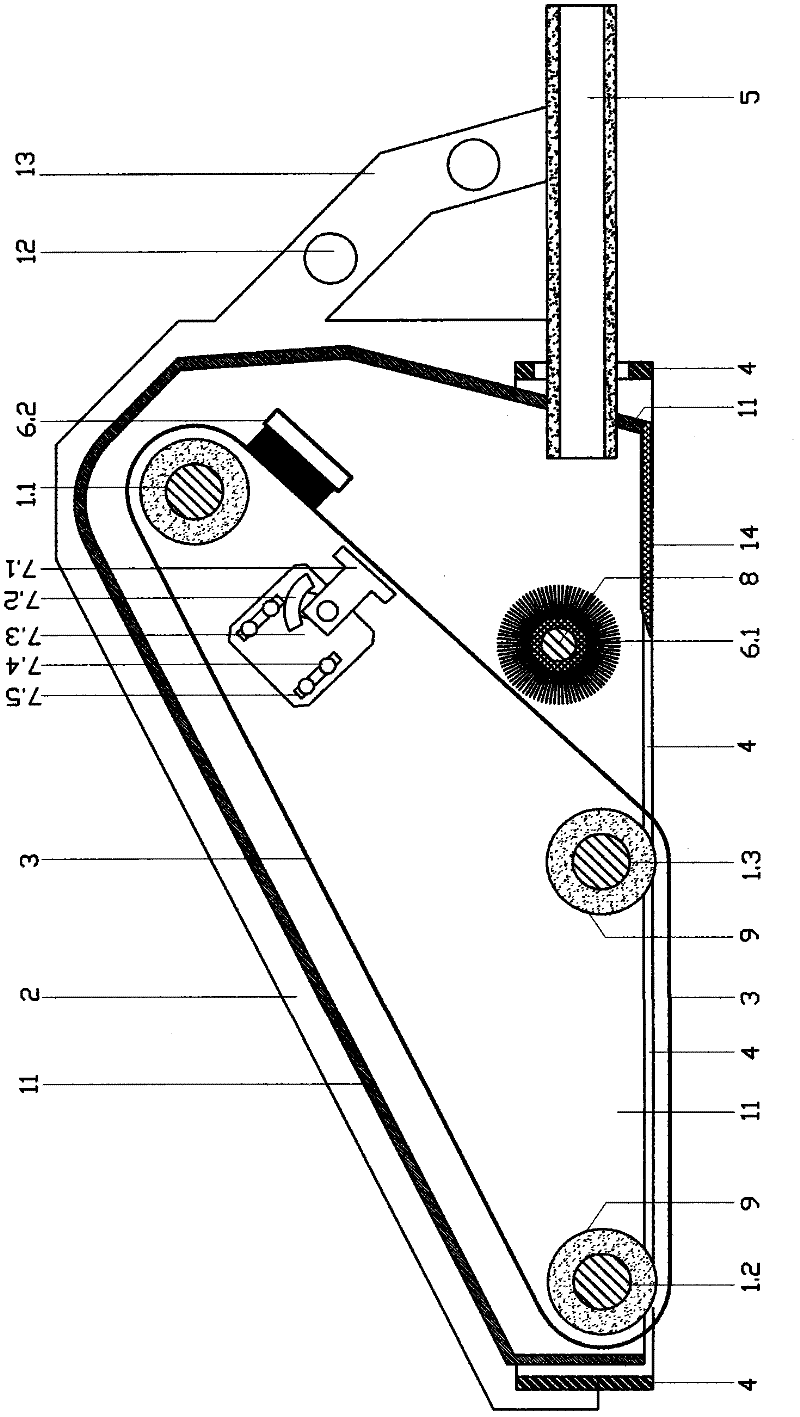

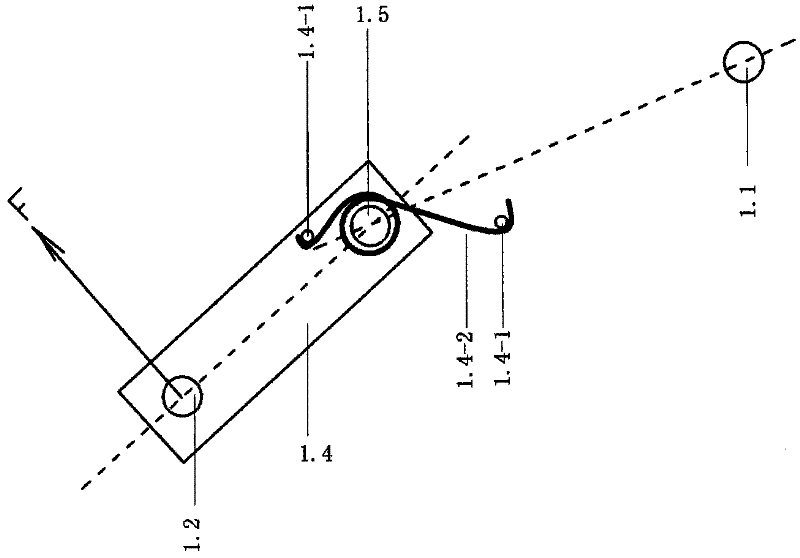

Embodiment Construction

[0151] Setting plan: assume that the grinding head is a multi-axis single abrasive belt model; assume that two fixed brushes and one rotating brush are used; assume that a shaft-type vibration mechanism is used to vibrate the abrasive belt; assume that the abrasive belt shaft is a single cantilever force-bearing structure ; The distance between the driven abrasive belt shaft and the driving shaft is adjusted in a sliding manner; there is no skirt plate under the balance frame.

[0152]1. Production of head frame (see Figure 17 ):

[0153] a. Select the type of abrasive belt and determine the circumference of the abrasive belt;

[0154] b. Select the diameter of the abrasive belt cylinder;

[0155] c. According to the perimeter of the abrasive belt and the diameter of the abrasive belt cylinder, determine the distance between the active abrasive belt axis, the driven abrasive belt axis, and the auxiliary abrasive belt axis; the perimeter of the triangle formed by connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com