Biomass microwave pyrolysis directional gasification system

A gasification system and biomass technology, applied in the field of biomass microwave pyrolysis directional gasification system, can solve the problems of sawdust falling into the track, falling out, and machine jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

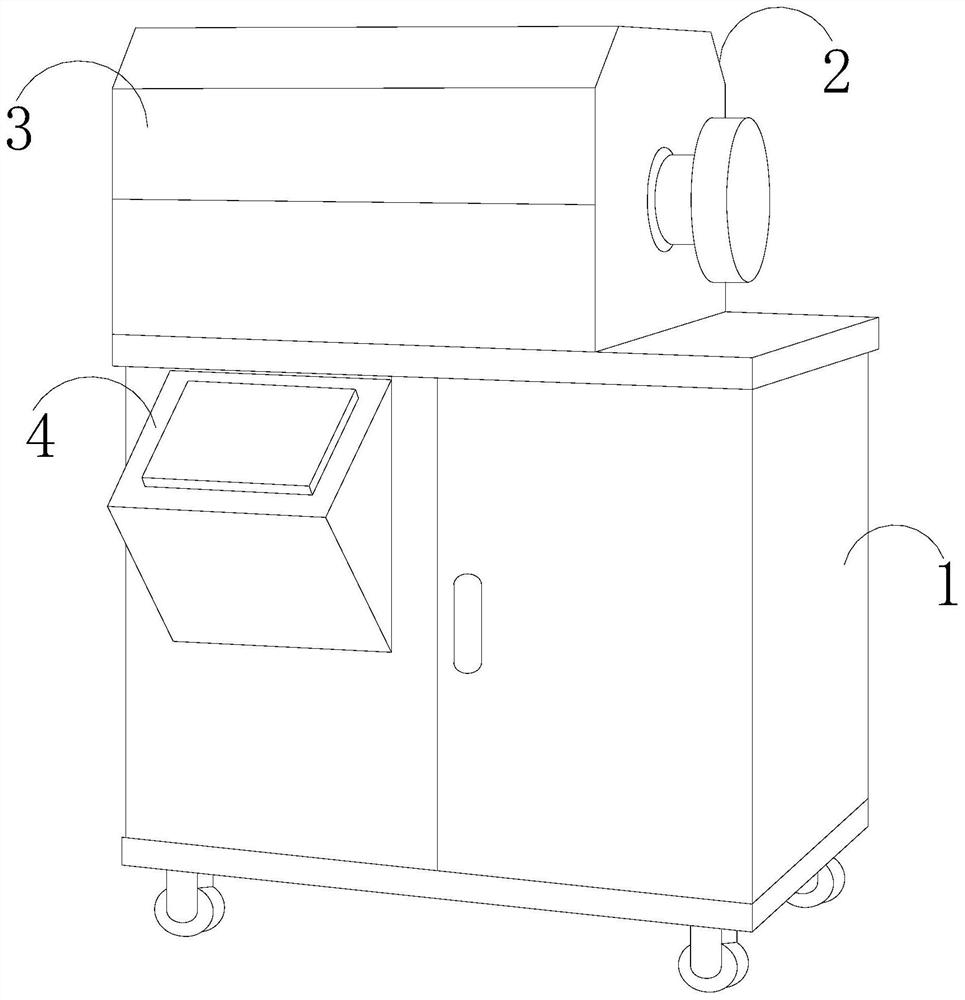

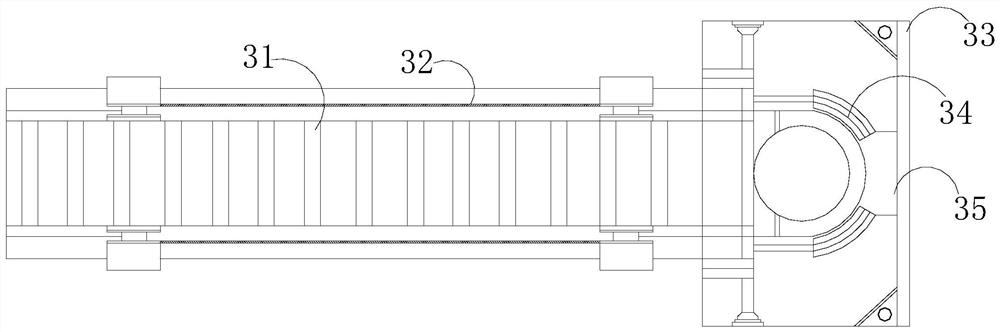

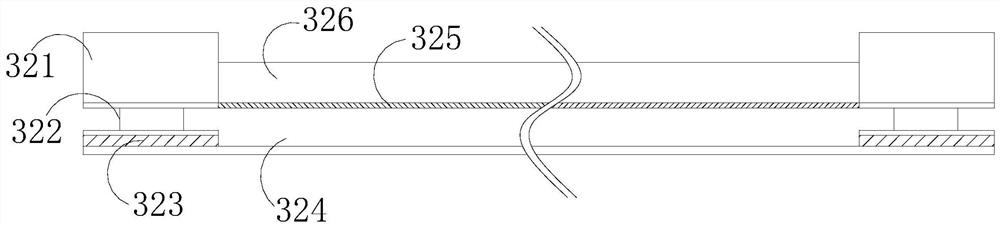

[0026] Such as Figure 1-Figure 6 As shown, the present invention provides a biomass microwave pyrolysis directional gasification system, its structure includes a cabinet 1, a dust cover 2, a feed port 3, a control panel 4, the cabinet 1 is fixed with a dust cover 2, The dust cover 2 is provided with a feeding port 3, the control panel 4 is installed on the chassis 1 and is electrically connected, and the feeding port 3 is located inside the dust cover 2 and is provided with a conveyor belt 31, Barrier mechanism 32, mounting seat 33, drive motor 34, connecting seat 35, the two sides of described conveying crawler belt 31 are matched with barrier mechanism 32, described mounting seat 33 is equipped with drive motor 34 and connecting seat 35, described The drive motor 34 is controlled by the control panel 4, and the drive motor 34 drives the transmission crawler belt 31. The side surface of the transmission crawler belt 31 is equipped with a baffle plate 311, and the barrier mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com