Active return-to-middle control system of electric wheel suspension

A control system and electric wheel technology, applied in the direction of automatic steering control components, suspensions, elastic suspensions, etc., can solve the problems of the influence of vehicle return characteristics, increase the moment of inertia of the steering system, complex structure, etc., and achieve compact structure and improved High return performance and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific content and working process of the present invention are further described below in conjunction with accompanying drawings.

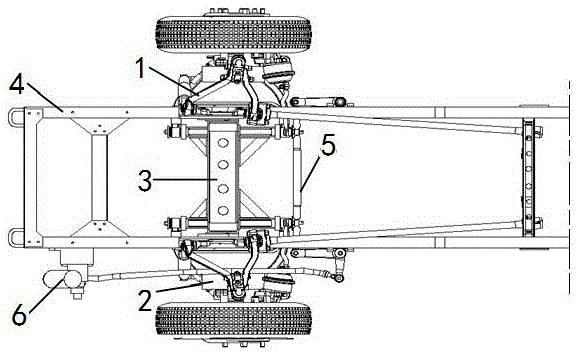

[0033] Such as figure 1 As shown, the present invention includes a suspension unit 1, an electric wheel unit 2, a bracket assembly 3, a vehicle frame 4, a steering mechanism 5 (a disconnected steering trapezoidal mechanism applied to an independent suspension in the prior art) and Actively return to the control device 6. Among them, the bracket assembly 3 is horizontally installed on the front end of the frame 4; the suspension unit 1 is symmetrically installed on both ends of the bracket assembly 3; the electric wheel unit 2 is installed on the suspension 1; the steering mechanism 5 is installed on the frame 4 Above, the active centering control device 6 controls the steering mechanism 5 to drive the electric wheel unit 2 to realize power steering or active centering control.

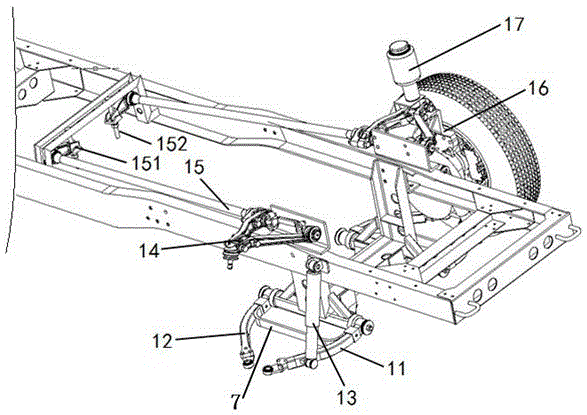

[0034] combine figure 2 , the suspension unit 1 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com