A solvent recovery system for dmf salty wastewater

A salt-containing wastewater, recovery system technology, applied in alkali metal halide purification, organic chemistry, carboxylic acid amide separation/purification, etc., can solve the problems of equipment corrosion, rectification tower blockage, cumbersome pre-treatment and post-treatment processes, etc. , to achieve the effect of simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

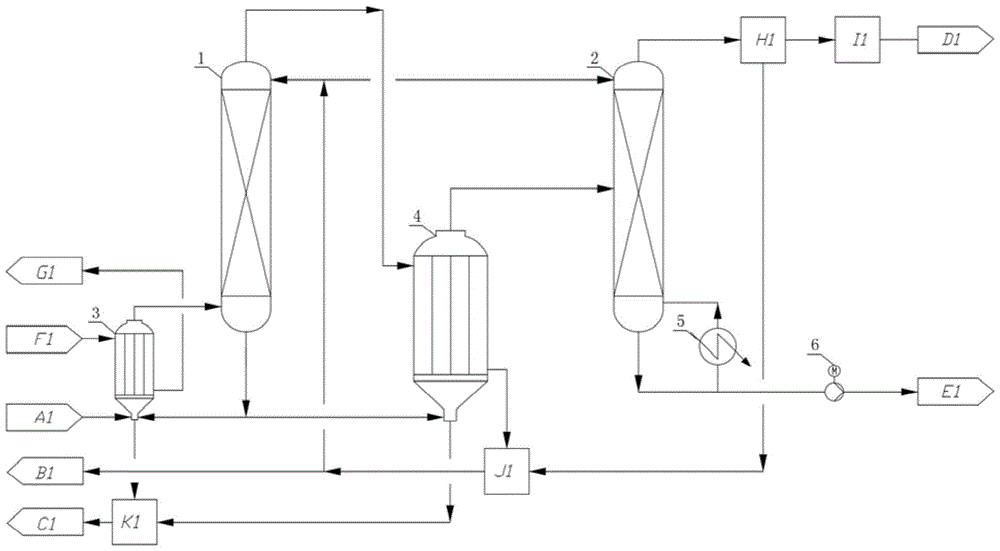

[0023] A kind of solvent recovery system of DMF saline waste water (see figure 1 ) comprises a first-effect evaporator 3, a first-effect rectification tower 1, a second-effect evaporator 4 and a second-effect rectification tower 2, the feed port at the bottom of the first-effect evaporator 3 is connected to DMF saline waste water A1, and the first-effect evaporator 3 The outlet at the top of the top is connected to the bottom of the first-effect rectification tower 1 through pipelines, and the bottom of the first-effect rectification tower 1 is connected to the bottom of the first-effect evaporator 3 and the second-effect evaporator 4 through pipelines respectively, and the first-effect rectification The top of tower 1 passes through the second-effect evaporator 4 through the pipeline and is connected to the reflux system J1; the upper part of the first-effect evaporator 3 is connected to the heat source F1 through the pipeline, and the lower part of the first-effect evaporator...

Embodiment 2

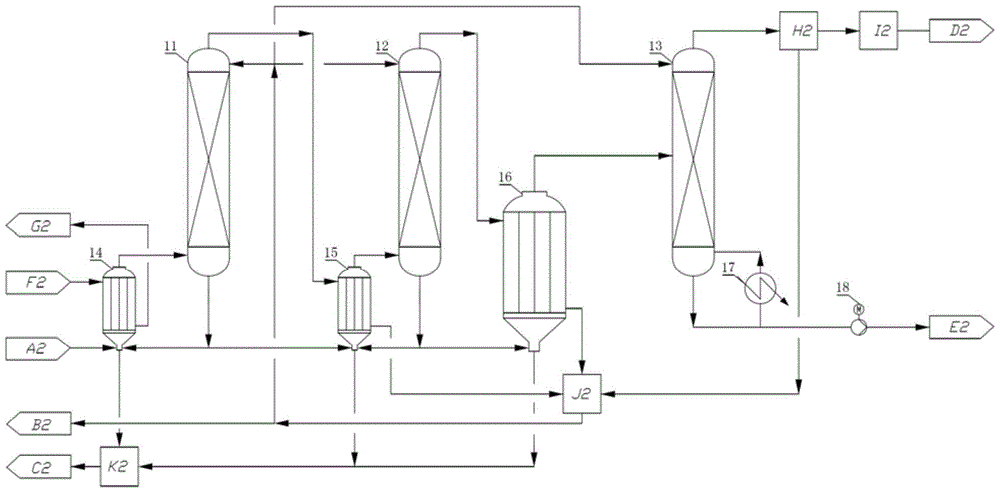

[0027] The solvent recovery system of the second DMF saline wastewater (see figure 2 ), comprising one-effect evaporator 14, one-effect rectifying tower 11, two-effect evaporator 15, two-effect rectifying tower 12, three-effect evaporator 16, three-effect rectifying tower 13, the inlet at the bottom of one-effect evaporator 14 The feed port is connected to the DMF saline waste water A2, and the outlet at the top of the first-effect evaporator 14 is connected to the bottom of the first-effect rectification tower 11 through a pipeline, and the bottom of the first-effect rectification tower 11 is respectively connected to the first-effect evaporator 14 through a pipeline. It is connected with the bottom of the second-effect evaporator 15, and the top of the first-effect rectification tower 11 is connected with the reflux system J2 after passing through the second-effect evaporator 15 through a pipeline; the upper part of the first-effect evaporator 14 is connected with the heat s...

Embodiment 3

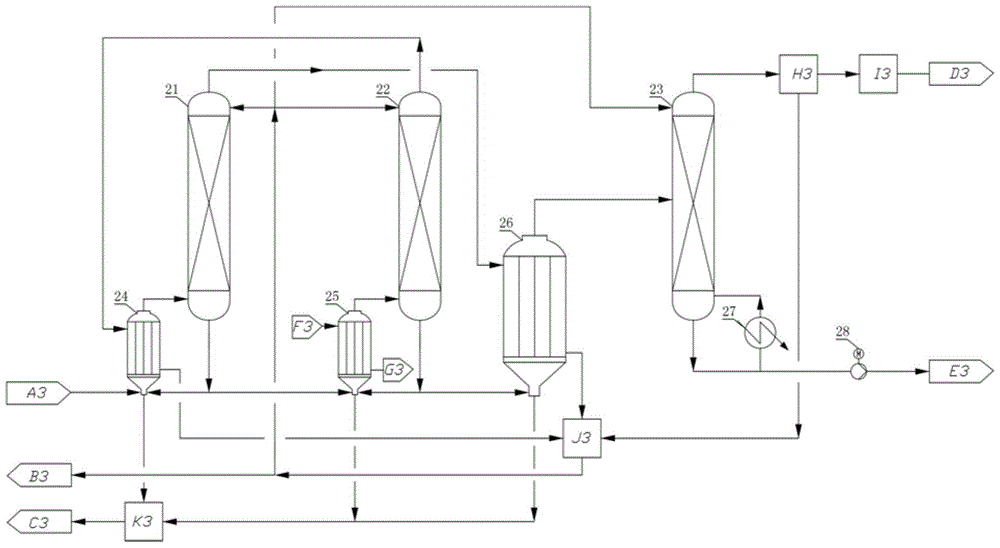

[0031] The solvent recovery system of the third DMF saline wastewater (see image 3 ), comprising one-effect evaporator 24, one-effect rectifying tower 21, two-effect evaporator 25, two-effect rectifying tower 22, three-effect evaporator 26, three-effect rectifying tower 23, the inlet at the bottom of one-effect evaporator 24 The feed port is connected to the DMF saline waste water A3, and the outlet at the top of the first-effect evaporator 24 is connected to the bottom of the first-effect rectification tower 21 through a pipeline, and the bottom of the first-effect rectification tower 21 is respectively connected to the first-effect evaporator 24 through a pipeline. It is connected with the bottom of the second-effect evaporator 25, and the top of the first-effect rectification tower 21 is connected with the reflux system J3 after passing through the three-effect evaporator 26 through a pipeline; the top of the second-effect evaporator 25 is connected with the second-effect r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com