A kind of separation system and separation method of polyolefin catalyst mother liquor

A polyolefin catalyst and separation method technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, distillation purification/separation, etc., can solve problems such as tower blockage, achieve tower blockage, low energy consumption, and high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

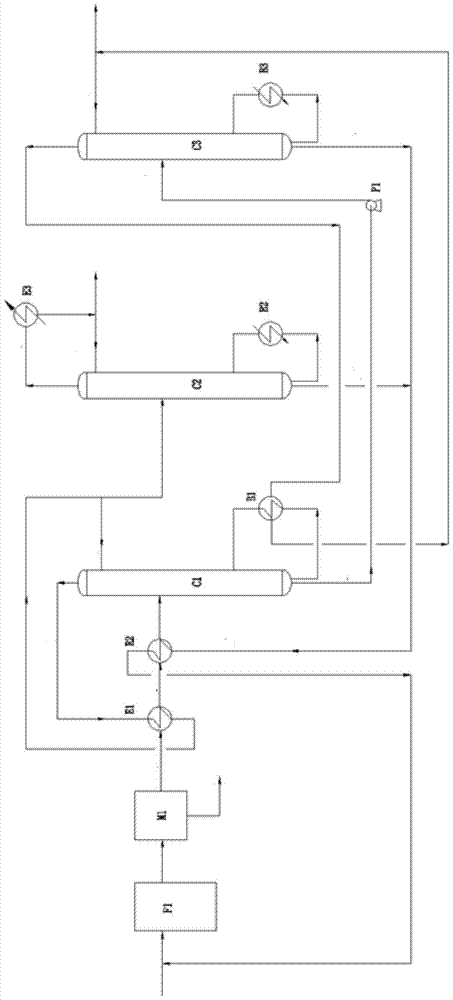

[0062] Such as figure 1 Shown, a kind of polyolefin catalyst mother liquid separation system.

[0063] Including: the first fractionation tower C1, the second fractionation tower C2, the third fractionation tower C3, the first fractionation tower condenser E1, the feed heat exchanger E2 and the second fractionation tower condenser E3; before the first fractionation tower C1 Equipped with refrigeration equipment F1 and solid-liquid separation equipment M1;

[0064] The refrigeration equipment F1 is connected to the solid-liquid separation equipment M1, the first fractionation tower condenser E1, and the feed heat exchanger E2 in sequence, and then connected to the first fractionation tower C1; the top outlet pipeline of the first fractionation tower C1 is connected to the first fractionation tower condenser E1 The pipeline is divided into two branches, one is connected to the upper part of the first fractionating tower C1, and the other is connected to the second fractionating...

Embodiment 2

[0077] The system and method are the same as in Embodiment 1.

[0078] A kind of mother liquor feed rate of polyolefin catalyst is 1000kg / h, and wherein the content of titanium tetrachloride is 80% (weight), and the content of hexane is 15%, and the content of high boilers such as chlorinated hydrocarbyl titanium, fat is 5%, first enter the freezer at a low temperature of -20°C to freeze and solidify most of the high boilers, the operating pressure of the freezer is 110KPa, and then enter the centrifuge for separation. The weight of the centrifuged solid residue is 52.94kg / h. content is 85%, the titanium tetrachloride content in the solid slag is 12%, and the hexane content is 3%, and the weight of the mother liquor after centrifugation is 947.06kg / h, and the titanium tetrachloride content in the mother liquor is 83.8%. The alkane content is 15.67%, and the high boiler content is 0.53%. After the gas-phase heat exchange between the heat exchanger E1 and the top of the C1 tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com