High-efficient gas-liquid mass transferring device

A high-efficiency, gas-liquid exchange technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of low gas purification degree and large volume of desulfurization tower, so as to improve the purification degree, remarkable application effect and easy operation The effect of great elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

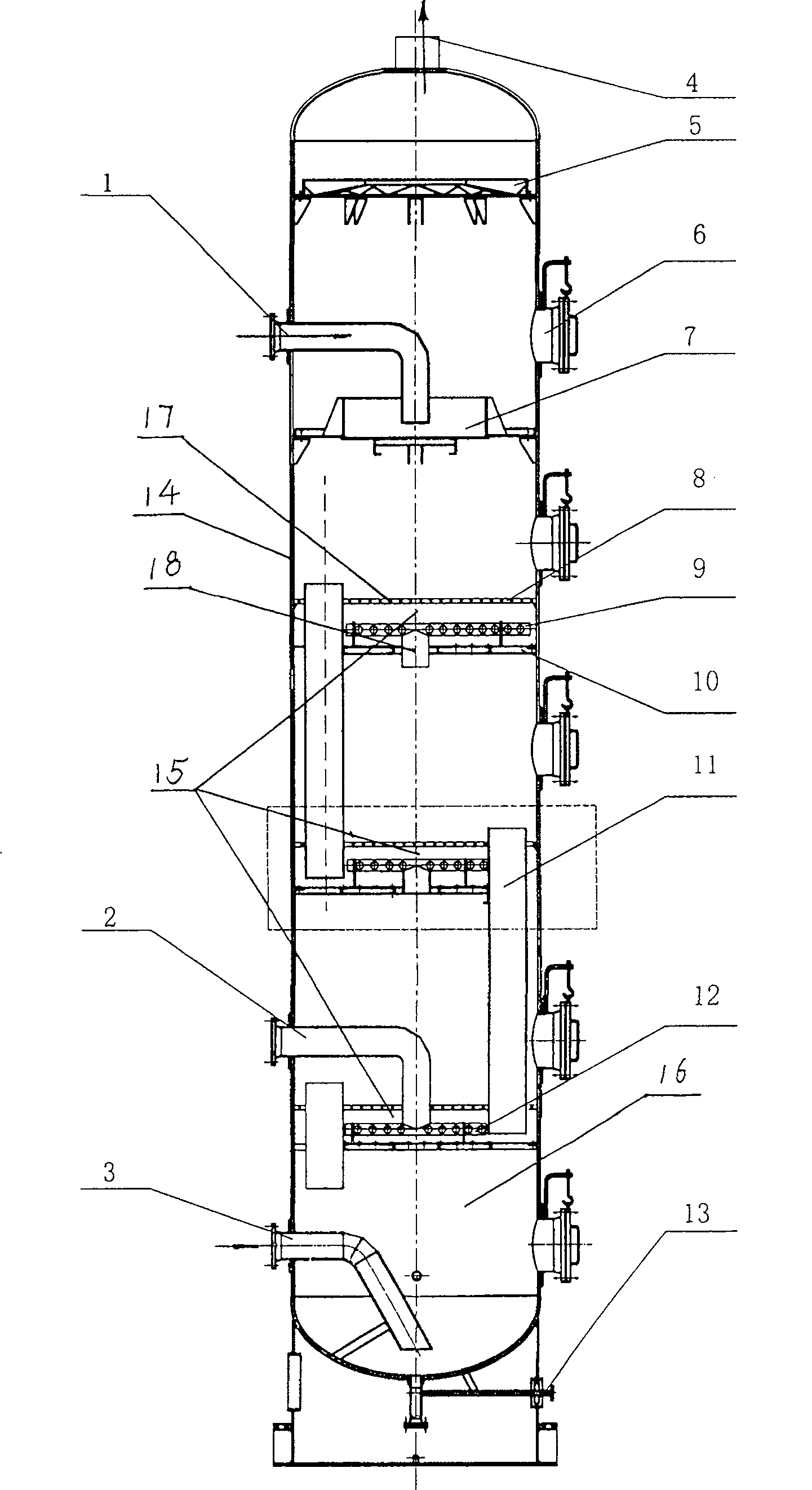

[0012] As shown in Figure 1, the tower body 14 is provided with a defoaming plate 5, a liquid distributor 7 and a multi-stage gas-liquid exchange mechanism 15 from top to bottom (this embodiment is a three-stage gas-liquid exchange mechanism, which can also be based on the vulcanization in the gas. The level of hydrogen content determines the number of stages used), the bottom of the tower body 14 is a liquid collection chamber 16, and the gas-liquid exchange mechanism 15 includes an upper redistribution plate 8, a middle bubble redistributor 9 and a bottom baffle 10 , distribution holes 17 are evenly distributed on the redistribution plate 8, the bubble redistributor 9 is a cavity structure, and the air outlet holes 18 are distributed on the surface, so that the bubbles are broken to form bubble groups. Unicom, the downcomer 11 is arranged between the two gas-liquid exchange mechanisms 15, the upper nozzle of the downcomer 11 is located on the plane of the redistribution plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com