Separation method for recovering olefin polymerization catalyst mother liquid

A separation method and mother liquor recovery technology, applied in the direction of distillation purification/separation, titanium halide, etc., can solve the problems of device material consumption, tower blockage, high energy consumption, etc., achieve the effects of reduced consumption, improved recovery rate, and saved device investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

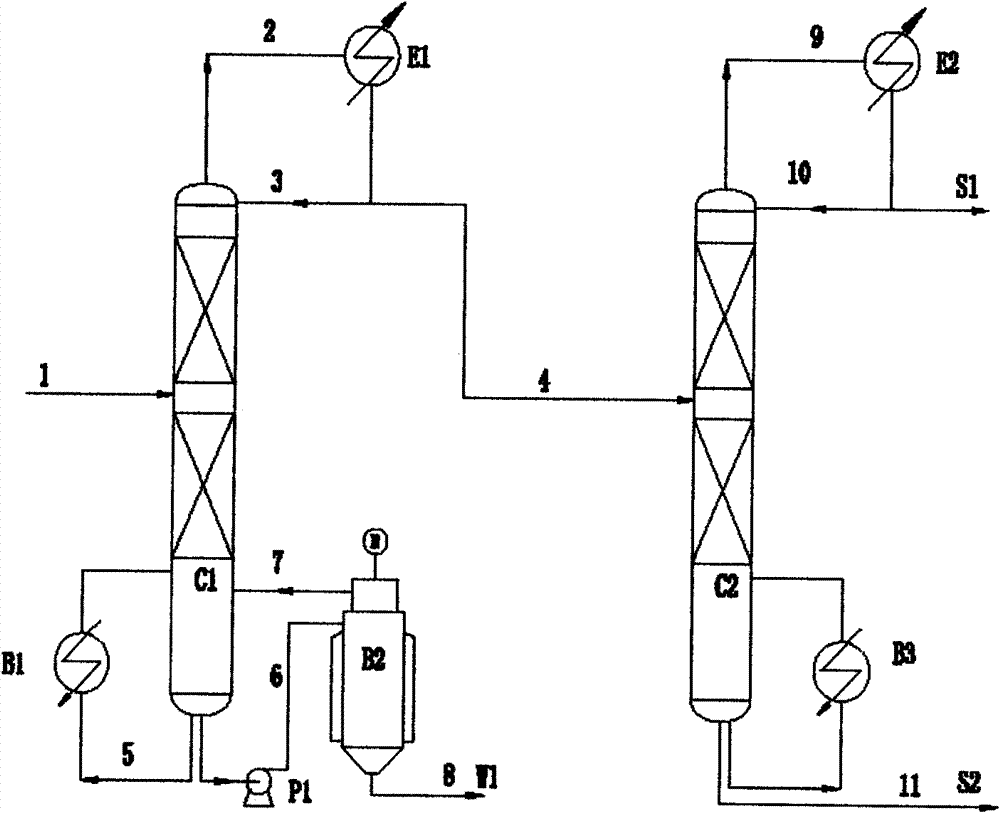

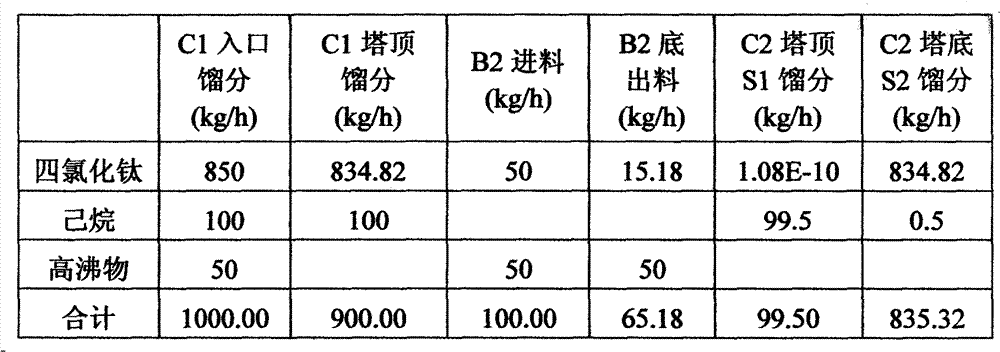

Embodiment 1

[0030] A kind of mother liquor of polyolefin catalyst, wherein the content of titanium tetrachloride is 80% (weight), and the content of hexane is 15%, and the content of heavy component high boiler is 5%, enters the first fractionation column through pipeline 1, The feed rate is 1000kg / h, the first fractionation tower is a packed tower, and the filler is IMTP25# bulk packing. The theoretical plate number of the tower is 15, and the pressure at the top of the tower is 105KPa. The titanium tetrachloride and hexane produced at the top of the tower are The fraction is sent to the second fractionation tower C2 through pipeline 4, and the bottom material enters the wiped-film evaporator, and the gas phase returns to the first fractionation tower, and the high-boiler containing part of titanium tetrachloride is extracted from the bottom of the wiped-film evaporator, and the high-boiler The weight ratio of titanium tetrachloride to titanium tetrachloride is 3.61, and it will be discha...

Embodiment 2

[0037] A kind of mother liquor of polyolefin catalyst, wherein the content of titanium tetrachloride is 85% (weight), and the content of hexane is 10%, and the content of heavy component high boiler is 5%, enters the first fractionation column through pipeline 1, The feed rate is 1000kg / h, the first fractionation tower is a packed tower, the rectification section and the extraction section all use IMTP 25# bulk packing, the theoretical plate number of this tower is 15, the pressure at the top of the tower is 50KPa, and the pressure at the bottom of the tower is 80KPa, the titanium tetrachloride and hexane fraction extracted from the top of the tower are sent to the second fractionation tower C2 through pipeline 4, and the bottom material enters the wiped film evaporator. The operating pressure of the wiped film evaporator is 60KPa, and the vapor phase evaporated by the wiped film evaporator Return to the first fractionation tower, extract high boilers containing part of titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com