Sinker swing mechanism

A swing mechanism and sinker technology, applied in textiles, papermaking, knitting, warp knitting, etc., can solve problems such as unreasonable design of sinker movement mechanism, unstable sinker swing, bad influence on fabric quality, etc., and achieve simple structure , low cost, convenient locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

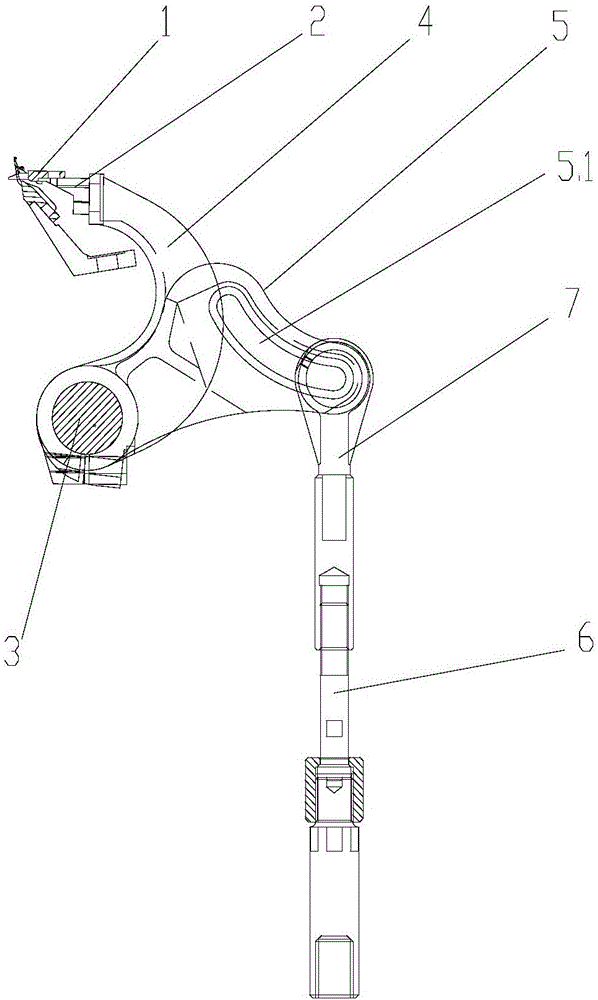

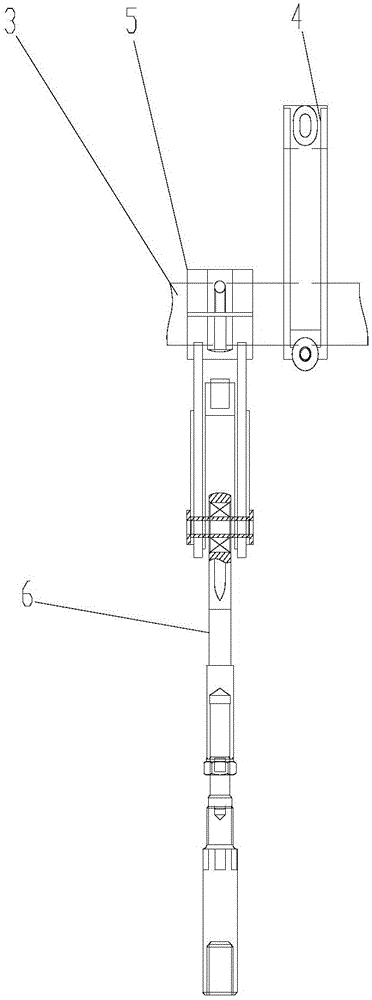

[0014] Such as figure 1 , figure 2 The sinker oscillating mechanism shown includes a sinker 1, a needle bed 2 for fixing the sinker 1, and a swing shaft 3. The needle bed 2 is fixed on one end of an arc-shaped auxiliary arm 4, and the auxiliary arm 4 faces to the side of the swing direction. Bending, so that it fits closely with other parts, reduces space occupation, and facilitates adjustment of the trajectory of the sinker 1. The other end of the auxiliary arm 4 is locked on the swing shaft 3, and the end of the auxiliary arm 4 is sleeved on the swing shaft. The locking part is locked on the holding shaft 3 with a locking screw, the swing of the pendulum shaft 3 is controlled by the main arm 5, one end of the main arm 5 is locked on the pendulum shaft 3, and the end of the main arm 5 There is also a circular locking part, the locking part is locked on the swing shaft 3 with a locking screw, the other end of the main arm 5 is connected with the push rod 6 that pushes the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com