Five-segment-type millisecond electric detonator secondary blasting construction method applied to blasting of high-gas large-section tunnel

A secondary blasting and construction method technology, applied in the field of blasting, can solve the problems that cannot be applied to the environment with methane and coal dust, and achieve the effect of improving construction efficiency and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

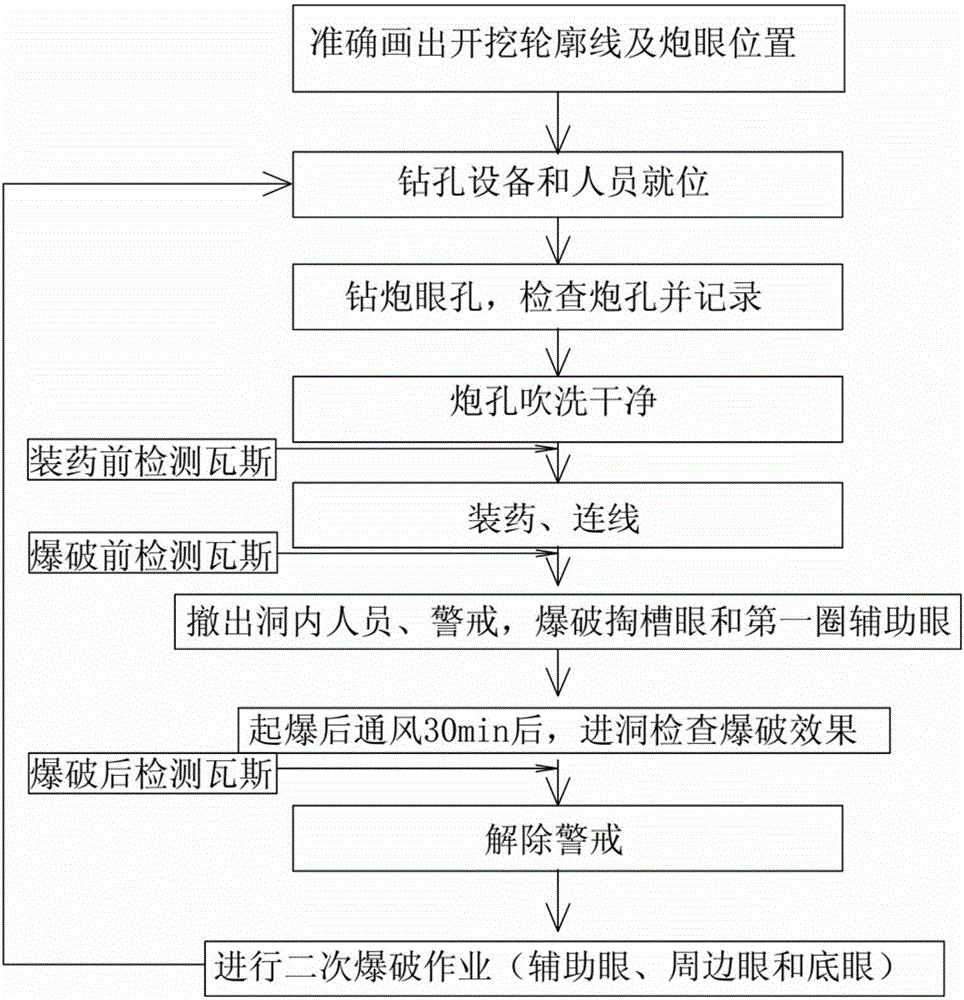

[0024] (1) blasting test: before the blasting construction of the present invention, prepare corresponding blasting test outline, after design approval, select different mileage sections, carry out blasting test, according to blasting test result, adjust blasting parameter, until obtaining best blasting effect, Take the adjusted blasting parameters as the basis for on-site blasting and excavation;

[0025] (2) Surface scum cleaning: In front of the construction gun, excavators are used to clean loose rocks or rock blocks on the excavation face to ensure the safety of the construction environment.

[0026] (3) Measurement: Before drilling, measuring technicians measure the section size of the tunnel face and the coordinates of the centerline (cross-line position), and provide the on-site pre-blasting conditions to the technicians and the drilling team.

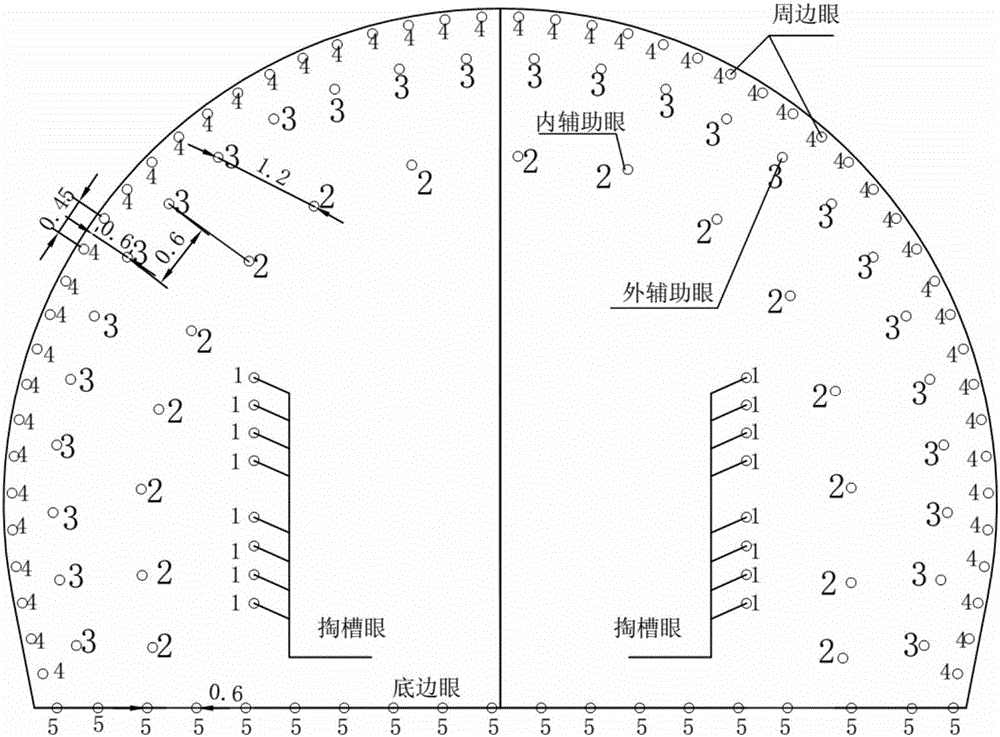

[0027] (4) Design: The technicians carry out the blasting design according to the on-site measurement results, determine the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com