One-piece ceramic capacitance pressure transducer and manufacture method

A pressure sensor, ceramic capacitor technology, applied in the direction of fluid pressure measurement, instrument, measurement force, etc. using capacitance change, can solve the problems of product sealing and bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

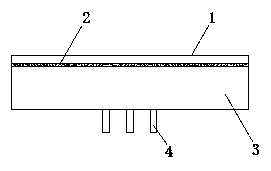

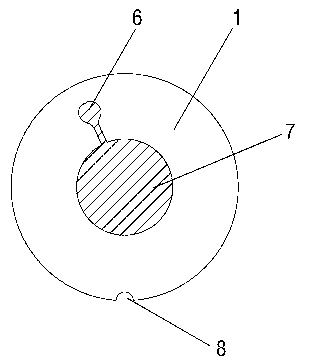

[0029] Such as image 3 As shown, the elastic thin substrate 1 is circular and has a thickness of 0.3-0.8 mm. The elastic thin substrate 1 is a tape-cast alumina or zirconia green ceramic sheet, on which a thin substrate metal electrode 7 and a thin substrate electrode pad 6 are fabricated by screen printing or vacuum sputtering, and its thickness is 0.5-1 μm . The edge of the elastic thin substrate 1 is provided with a thin substrate positioning notch 8 . The thin substrate metal electrode 7 is concentric with the circular elastic thin substrate 1 . When the pressure sensor is subjected to external pressure, the elastic thin substrate is elastically bent along the thickness direction of the plate.

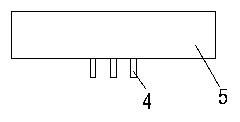

[0030] Such as Figure 4 As shown, the thick substrate 3 is circular and has a thickness of 3-8 mm. On the thick substrate 3, the thick substrate metal electrode 10 and the ring metal electrode 11 surrounding the thick substrate metal electrode 10 are also made by screen prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com