Spring swing life test device

A life test and crossbar technology, which is applied in the field of spring swing life test devices, can solve the problems of neglecting spring swing life and vibration device failure, and achieves the effect of reducing motion resistance and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

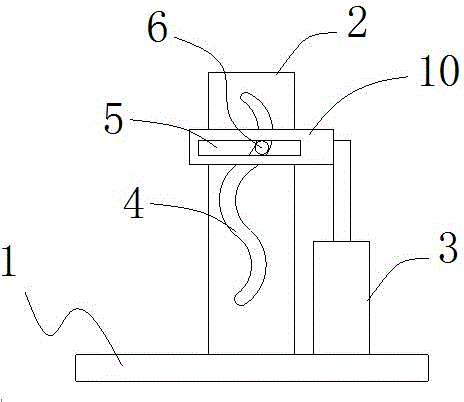

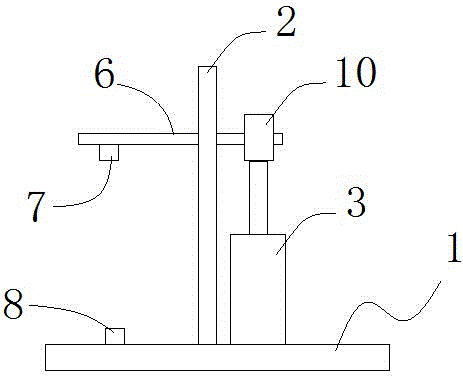

[0017] Such as figure 1 , 2 As shown, the spring swing life testing device of the present embodiment includes a base 1 and a support 2 and a cylinder 3 vertically fixed on the base 1, the support 2 is fixed with a horizontal block 10, and the horizontal block 10 is provided with a wave-shaped through groove 4, The piston rod end of the cylinder 3 is fixed with a horizontal through groove 5; a cross bar 6 is movably installed in the horizontal through groove 5, and the cross bar 6 passes through the wave-shaped through groove 4; One end of the rod 6 is provided with a first fixing part 7, and the base 1 is provided with a second fixing part 8;

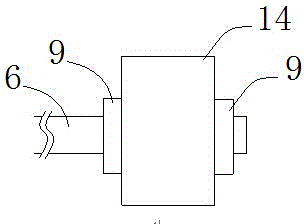

[0018] Such as image 3 As shown, the cross bar 6 is provided with an anti-off portion, and the anti-off portion is composed of the cross bar 6 body and two nuts 9, the cross bar 6 body is provided with threads, and the two nuts 9 are screwed on the cross bar 6 on the body, and two nuts 9 are respectively located on both sides of the...

Embodiment 2

[0021] Such as Figure 4 As shown, the difference from Embodiment 1 is that the anti-off part in this embodiment includes the body of the cross bar 6 passing through the horizontal channel 5 and the rollers installed on the upper and lower sides of the body of the cross bar 6 through the auxiliary bracket 11 12, wherein the upper and lower ends of the auxiliary bracket 11 each have two rollers 12 to maintain balance; the two sides of the rollers 12 are provided with anti-off edges 13, and the anti-off edges 13 of the rollers 12 are stuck in the horizontal channel Both sides of slot 5. The anti-off edge 13 of the above-mentioned roller 12 can prevent the end of the cross bar 6 from breaking out of the horizontal through groove 5, and the roller 12 can greatly reduce the movement resistance between the cross bar 6 and the horizontal through groove 5, so that the roller 12 can move in the horizontal through groove. Move within 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com