Tire lip removal test device

A testing device and tire technology, which is applied in the direction of automobile tire testing, etc., can solve problems such as inaccurate test results, and achieve the effects of avoiding errors, good versatility, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

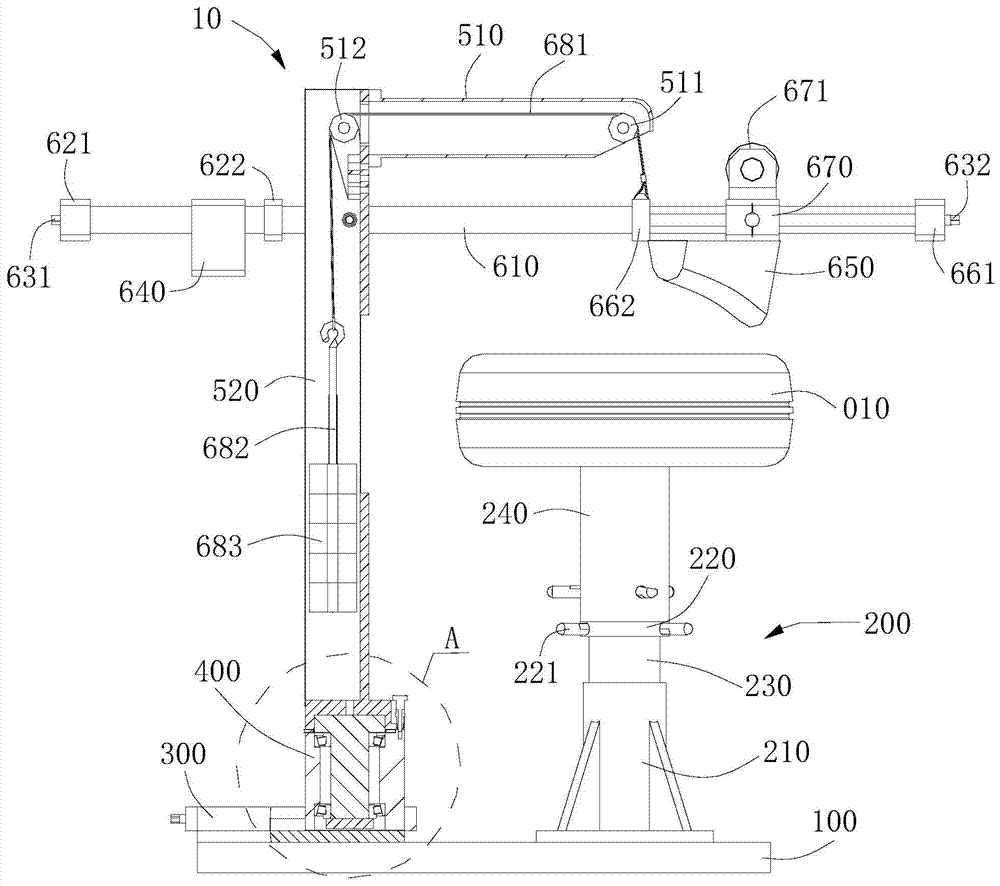

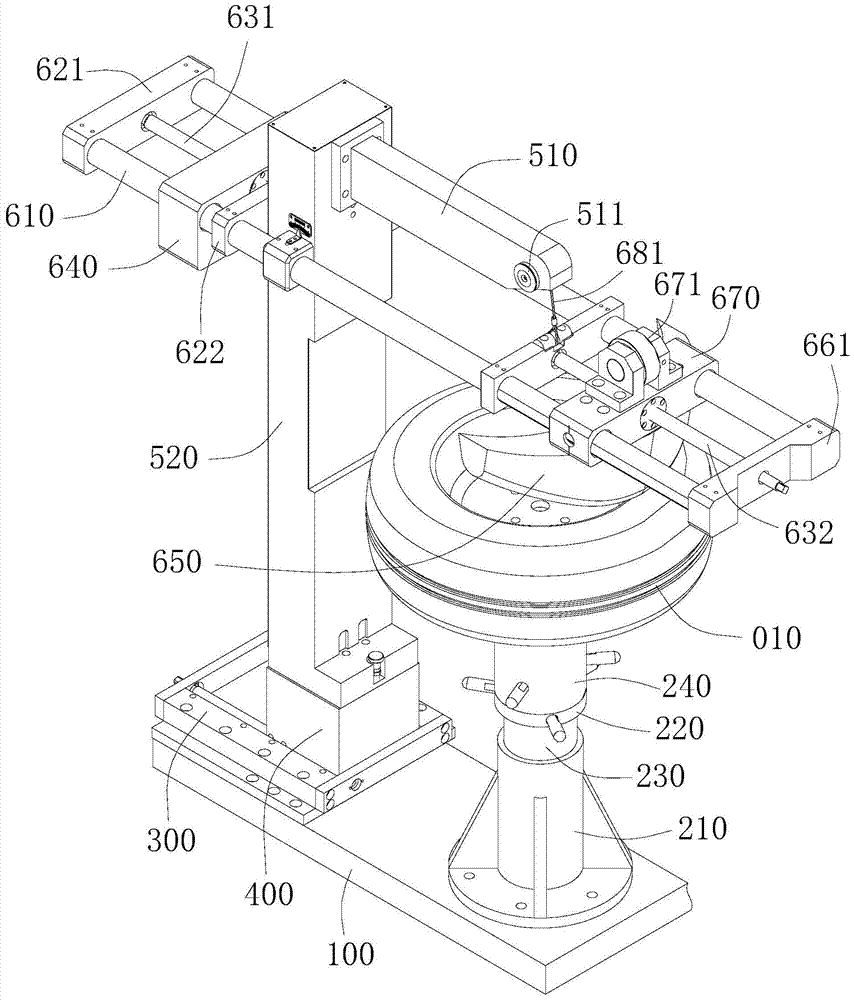

[0036] Such as figure 1 with figure 2 As shown, among them, figure 1 It is a partial sectional view of a tire lip detachment testing device 10 according to a preferred embodiment of the present invention, figure 2 for figure 1 A state diagram of the tire lip-off testing device 10 shown in FIG.

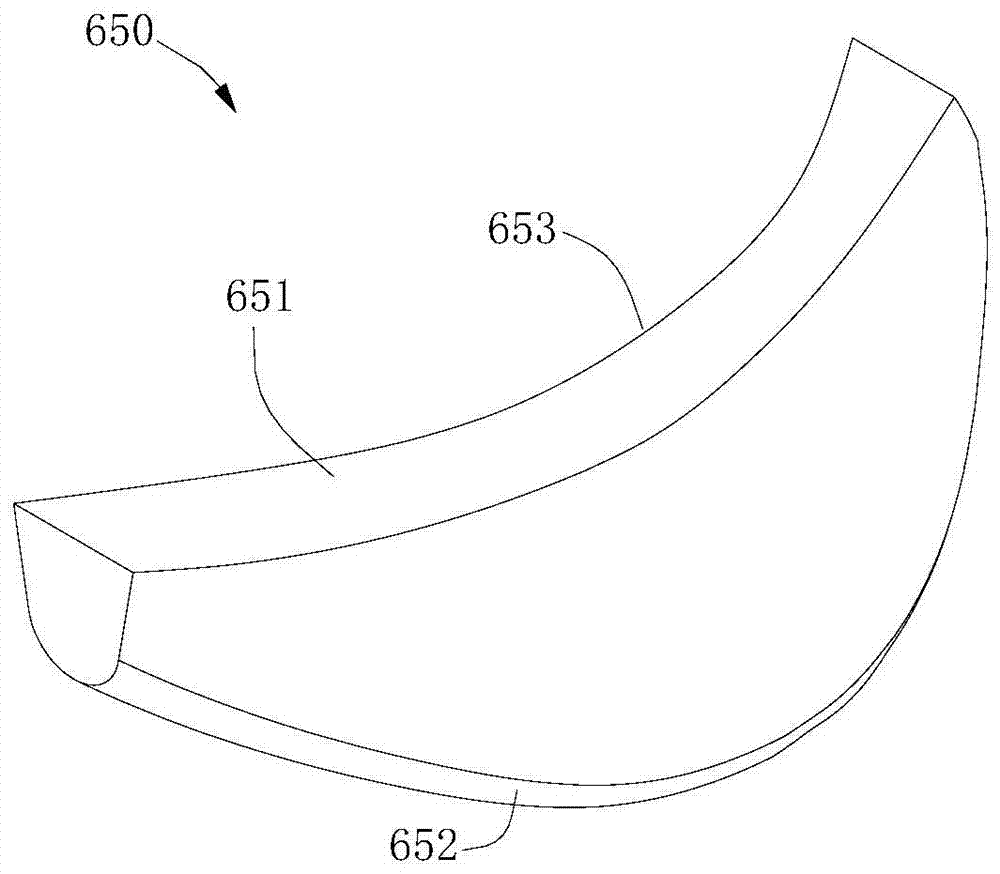

[0037] The tire lip removal test device 10 comprises: base 100, lifting mechanism 200, base 300, fixed base 400, stretching arm 510, support 520, guide rod 610, first end plate 621, second end plate 622, first screw mandrel 631 , a counterweight 640 , a second screw rod 632 , a pressing block 650 , a first end block 661 , a second end block 662 , a slider 670 , a rope 681 , a hook 682 and a weight 683 .

[0038] The lifting mechanism 200 and the base 300 are arranged on the base 100 at intervals, the fixing base 400 is slidably connected to the base 300 , the bracket 520 is rotatably connected to the fixing base 400 , and the stretching arm 510 is fixed on the bracket 520 and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com