A Steam Corrosion Fatigue Test System

A test system, corrosion fatigue technology, applied in the direction of weather resistance/light resistance/corrosion resistance, using repetitive force/pulse force to test the strength of materials, instruments, etc. Accuracy and reliability, improved safety performance, compact and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The working process of the present invention will be further described below in conjunction with the accompanying drawings.

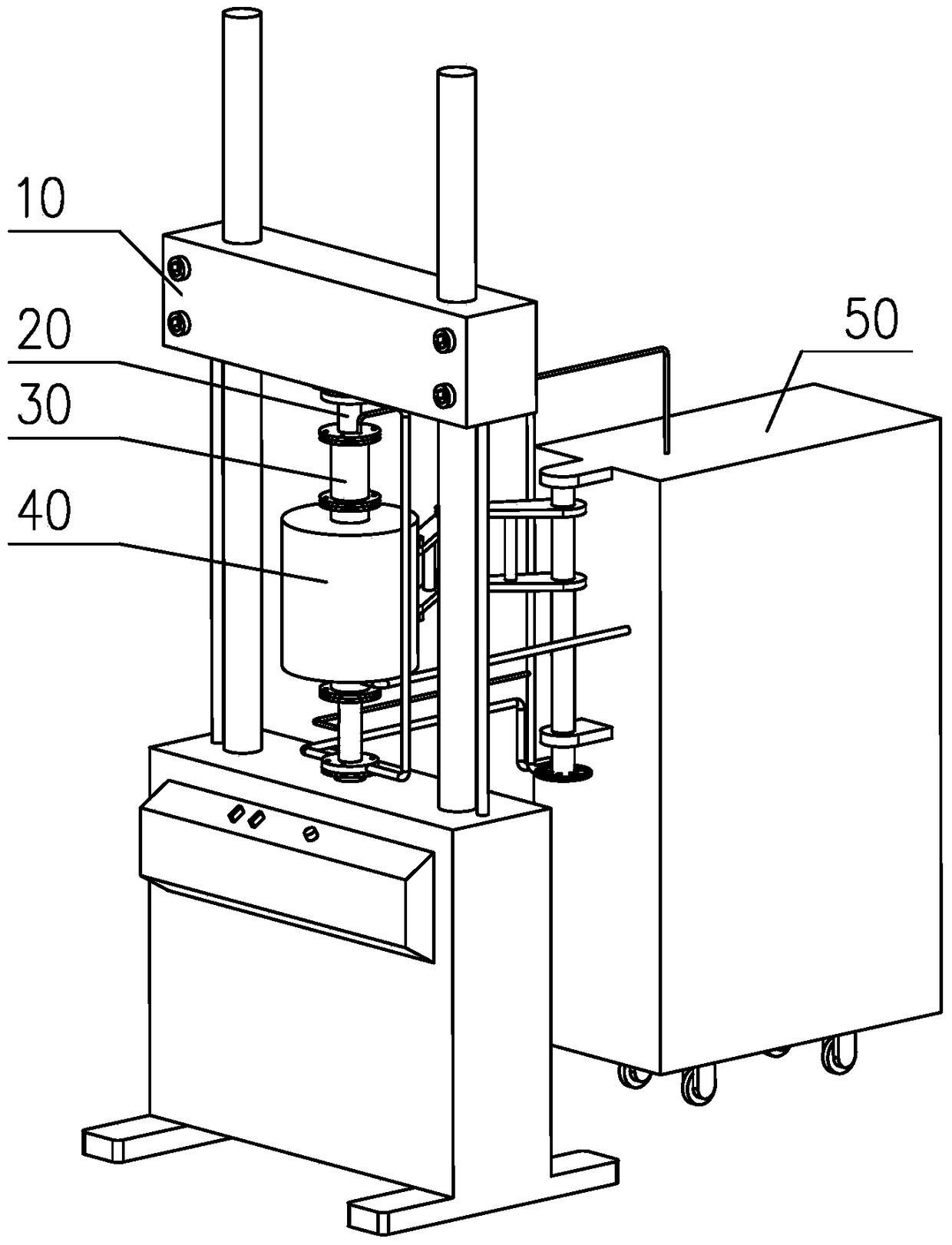

[0050] Such as Figure 1-7 As shown, the steam corrosion fatigue test system includes the following components: including a fatigue testing machine 10 , a fatigue loading fixture 20 , a steam environment sealing cylinder 30 , a heating furnace 40 , and a steam generating box 50 .

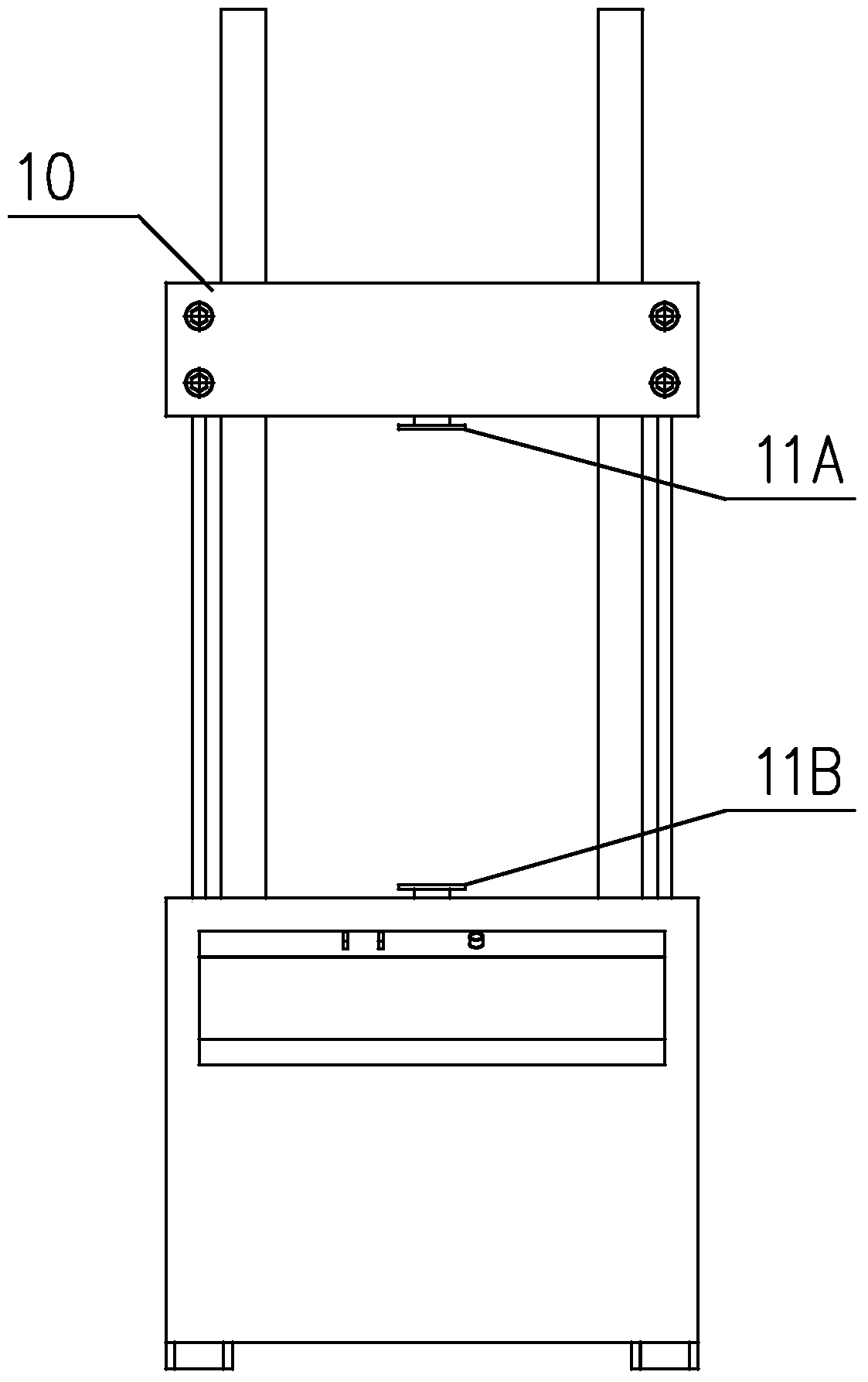

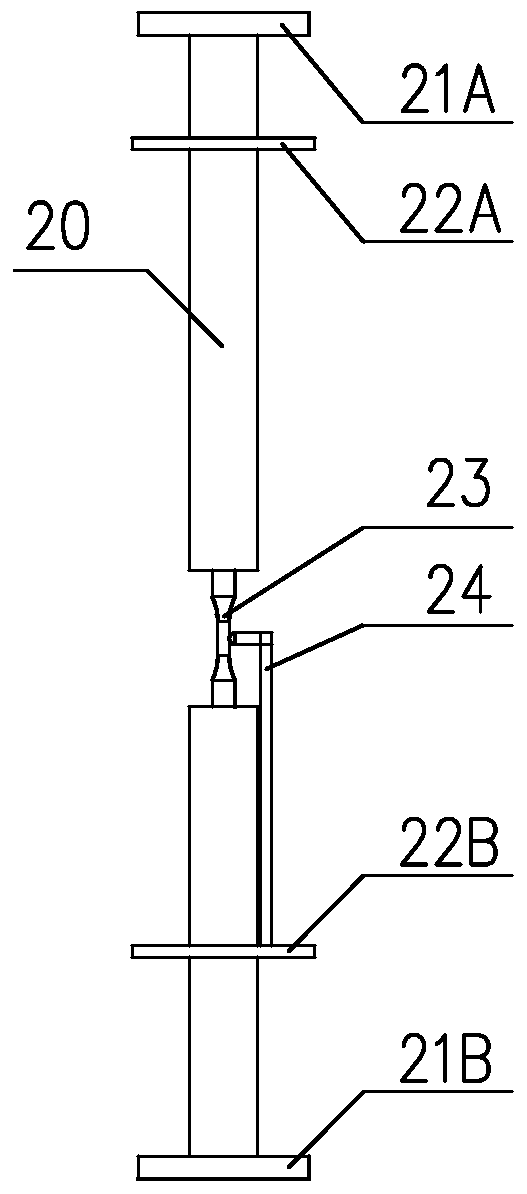

[0051] The fatigue testing machine 10 is provided with an upper flange 11A of the testing machine and a lower flange 11B of the testing machine, which are respectively connected to the upper connecting flange 21A and the lower connecting flange 21B of the fatigue loading fixture 20 for fatigue loading, as figure 2 , 3 shown.

[0052] The fatigue loading fixture 20 applies the fatigue load provided by the fatigue testing machine 10 to the fatigue sample 23 for testing, and the thermocouple 24 installed on the fatigue loading fixture 20 is used to test the test environm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com