Method for solving product assembly sequence planning problem on the basis of immune particle swarm algorithm

A technology for assembling sequences and immune particles, applied in computing, computing models, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

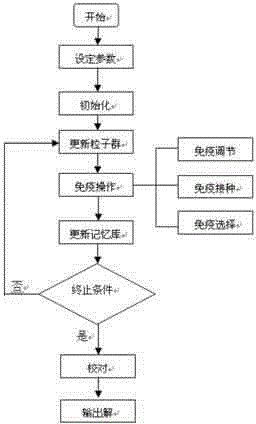

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

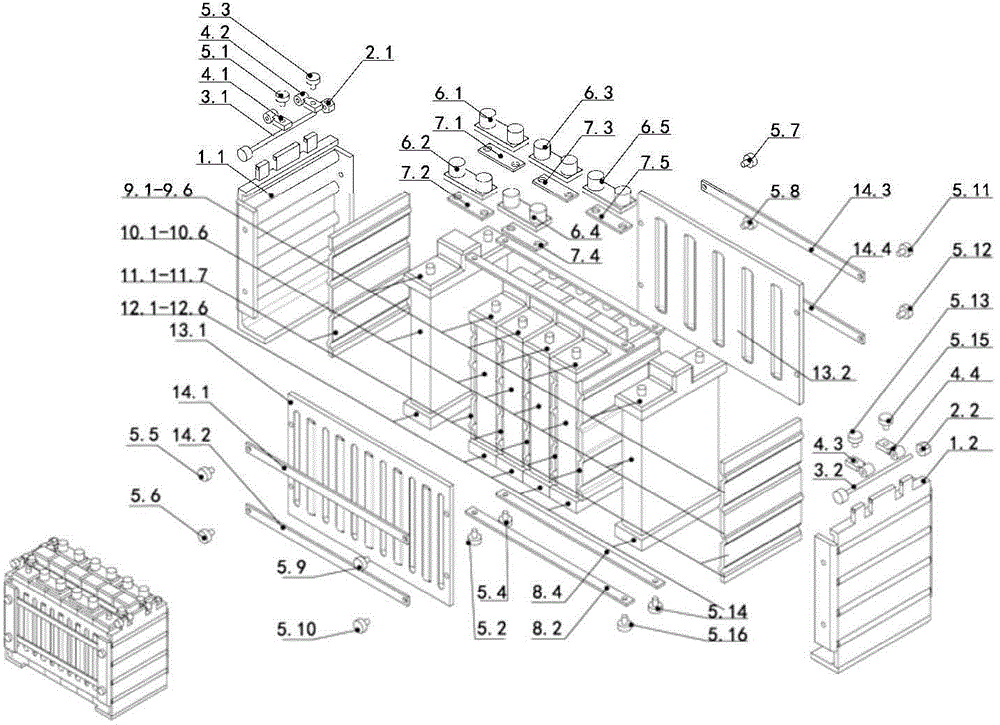

[0168] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0169] The following combination image 3 A lithium-ion power battery pack is shown as an application test of the algorithm

[0170] With the help of MATLAB software, product A ( image 3 )taking the test.

[0171] 1. Naming of parts:

[0172] Product A is a lithium-ion battery containing 71 elements ( image 3 ), which are listed in Table 1.

[0173] Table 1 Parts List of Product A

[0174] Part Number

Part Name

Part Number

part name

1.1~1.2

Platen

8.1~8.4

connecting plate

2.1~2.2

nut

9.1~9.6

insulation cover

3.1~3.2

screw

10.1~10.6

battery unit

4.1~4.4

connecting plate

11.1~11.7

cooling plate

5.1~5.16

bolt

12.1~12.6

Insulation base

6.1~6.5

insulating cap

13.1~13.2

side panel

7.1~7.5

Current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com