Evaluation method and apparatus for reinforcing bracket of automobile

An evaluation method and automobile technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of long design cycle and high cost of reinforced brackets, shorten the development cycle, reduce manpower, and meet the requirements of automobile driving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

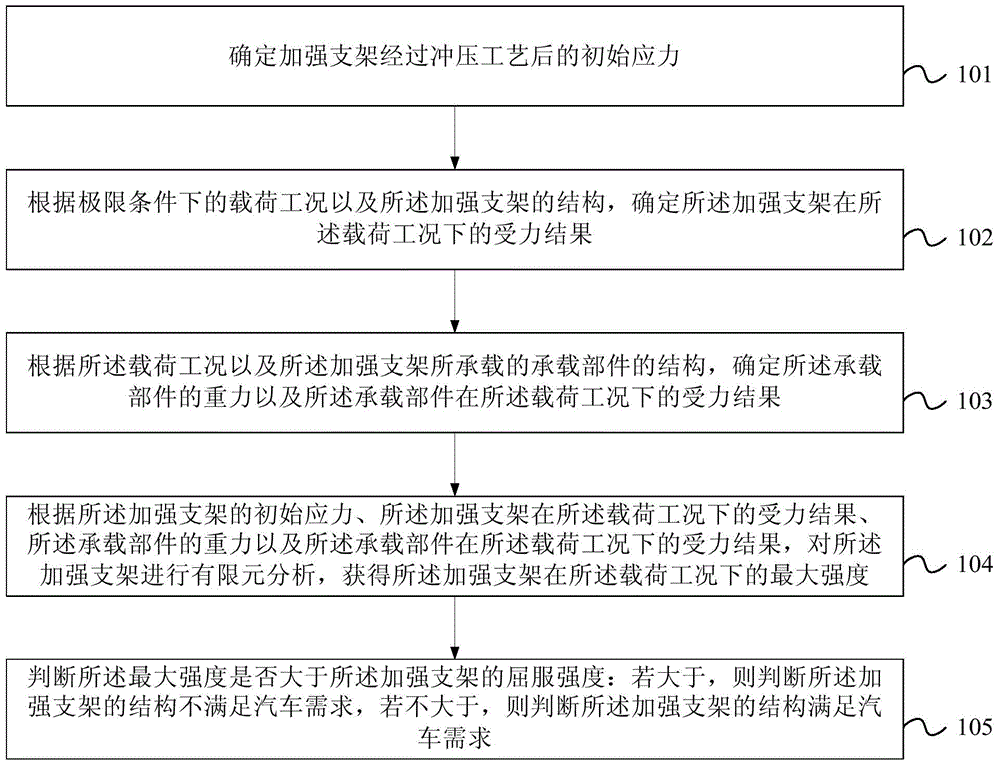

[0048] Embodiment 1 of the present invention provides an evaluation method for an automobile reinforcement bracket. figure 1 It is a flow chart of the evaluation method for the automobile reinforcement bracket provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the method in this embodiment may include:

[0049] Step 101, determine the initial stress of the reinforcing bracket after the stamping process.

[0050]The reinforcing bracket in this embodiment can be used to support the bearing parts of the key parts of the automobile. Wherein, the carrying part may be a battery, a wiper or an ECU (Electronic Control Unit, Electronic Control Unit), etc. Correspondingly, the reinforcing bracket may be a battery bracket, a wiper bracket, an ECU bracket, or the like. In order to ensure that the shape of the reinforcement bracket can better match the bearing parts or the vehicle body, the reinforcement bracket needs to be stamped and manufactured. Therefore,...

Embodiment 2

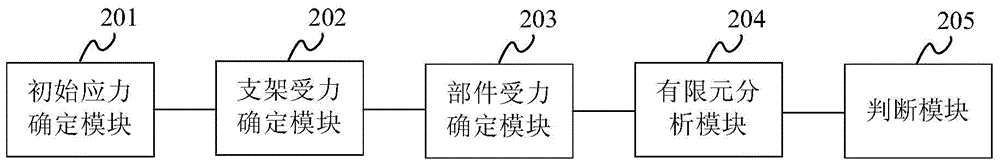

[0083] Embodiment 2 of the present invention provides an evaluation device for an automobile reinforcement bracket. figure 2 It is a schematic structural diagram of an evaluation device for an automobile reinforcement bracket provided in Embodiment 2 of the present invention. Such as figure 2 As shown, the automobile reinforcement bracket evaluation device in the present embodiment can include:

[0084] An initial stress determination module 201, configured to determine the initial stress of the reinforced bracket after the stamping process;

[0085] The support force determination module 202 is used to determine the force result of the reinforcement support under the load condition according to the load condition under the limit condition and the structure of the reinforcement support;

[0086] The component force determination module 203 is configured to determine the gravity of the load-bearing component and the force of the load-bearing component under the load condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com