High-speed railway ballastless track cable-stayed bridge steel truss combined girder structure

A ballastless track and cable-stayed bridge steel technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor structural performance, easy cracking, and low stiffness of the top surface of the steel bridge deck and the track base plate, and achieve the guarantee The effect of driving comfort, crack avoidance, and high structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

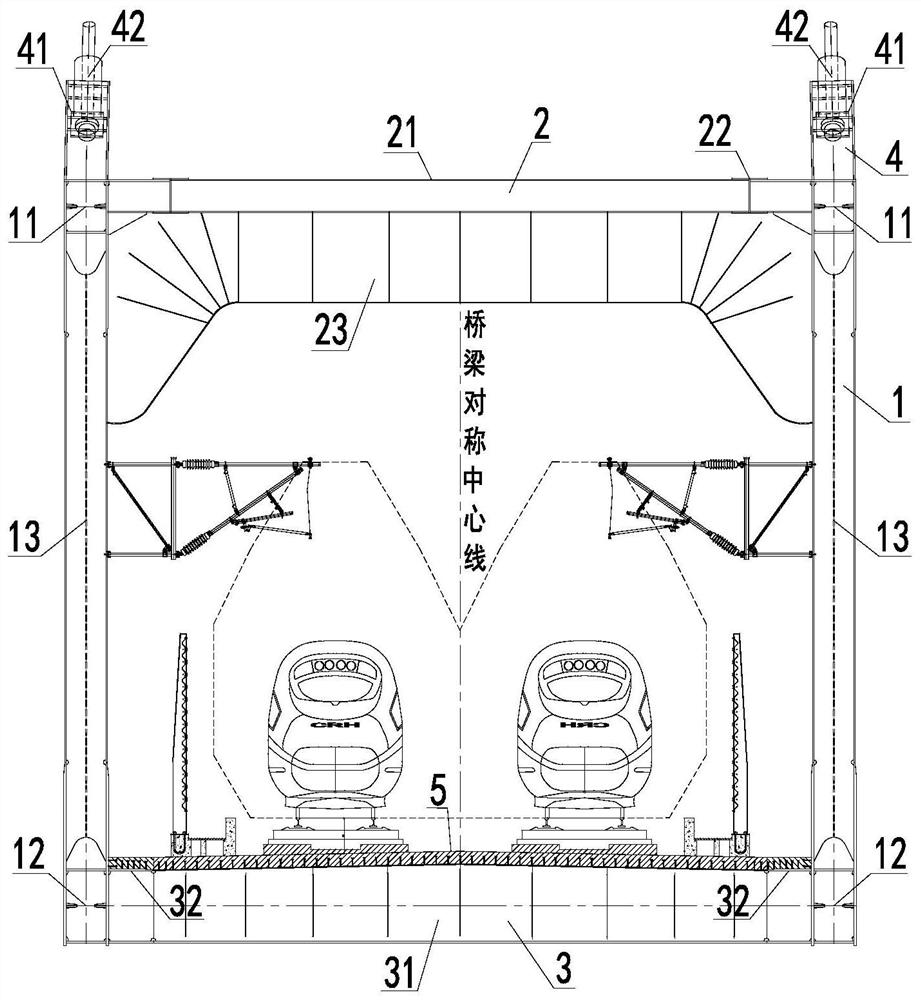

[0070] Such as figure 1 As shown, the high-speed railway ballastless track cable-stayed bridge combined main girder structure provided by the present invention includes a main truss 1 , a transverse connection system 2 , a combined bridge deck and a cable-stayed anchorage structure 4 .

[0071] The main truss 1 is arranged on both sides, and the transverse connection system 2 is arranged between the main trusses 1 and on the upper part of the first main truss; In the lower part, the concrete bridge deck 5 is arranged on the top surface of the steel beam 3 for laying the ballastless track slab. The stay cable anchoring structure 4 is arranged on the top surface of the main girder 1, and is used for anchoring the stay cables.

[0072] The main truss, transverse connection system, steel truss girder and cable-stayed anchorage structure form an internode structure, and one or two internodes form the overall section of the steel beam. During construction, the manufacture of the in...

specific Embodiment 2

[0074] This specific embodiment 2 is based on the specific embodiment 1, and further optimizes and improves the main girder and the transverse connecting system.

[0075] Such as Figure 4 As shown, the main truss 1 is arranged on both sides, including an upper chord 11, a lower chord 12 and a diagonal 13. The upper chord 11 and the lower chord 12 are arranged opposite to each other along the longitudinal bridge, and the upper chord 11 and the lower chord 12 are parallel. The diagonal web 13 is arranged between the upper chord 11 and the lower chord 12 , and the two ends of the diagonal web 13 are respectively welded between the upper chord 11 and the lower chord 12 . The upper chord 11, the lower chord 12 and the oblique web 13 are H-shaped cross-section rods or box-shaped cross-section rods, and the upper chord 11, lower chord 12 and diagonal web rods 13 form the triangular truss structure of the main truss 1, which improves the strength of the main truss 1. structural stif...

specific Embodiment 3

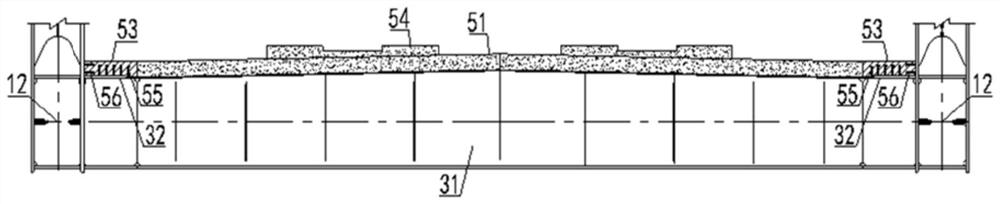

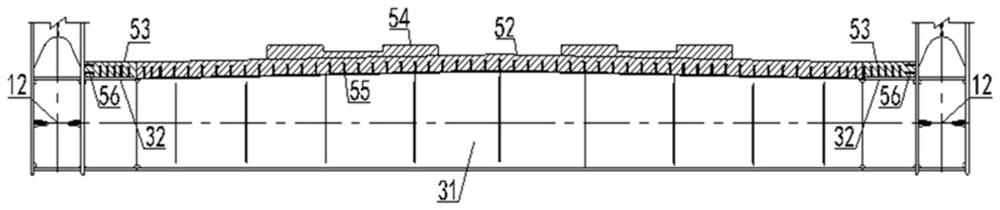

[0079] This specific embodiment 3 is based on the specific embodiment 2, and further optimizes and improves the steel beam and the concrete bridge deck.

[0080] Such as figure 2 , image 3 , Image 6 , Figure 7 with Figure 8 As shown, the steel beam 3 includes a lower beam 31 and a longitudinal long section 32, the lower beam 31 is arranged on the inner side of the lower part of the lower chord 12, and a plurality of lower beams 31 are equidistantly distributed along the longitudinal bridge direction. The long longitudinal section 32 is arranged on the top surface of the lower beam 31 , and the left and right ends of the long longitudinal section 32 are respectively welded to the inner web of the lower chord 12 .

[0081] The concrete bridge deck 5 includes a precast concrete deck 51 and a ballastless track base plate 54. Before assembling each precast concrete bridge deck 51, it is required to ensure that the concrete precast deck must have sufficient beam storage tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com