3D-printing-oriented halftone projection and model generation method

A 3D printing and model generation technology, applied in 3D modeling, 3D image processing, instruments, etc., can solve the problems of low light transmittance, poor light reflectivity and light transmittance of materials, uneven light transmission medium, etc., and achieve production cost Low, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0056] like Figure 8 As shown, a halftone projection method and model generation method for 3D printing, including the following steps:

[0057] (1) According to the input parameters, including the distance d between the model to be processed and the light source a and the distance d from the proposed model to the projection surface b , to establish a simulated projection scene for computer simulation.

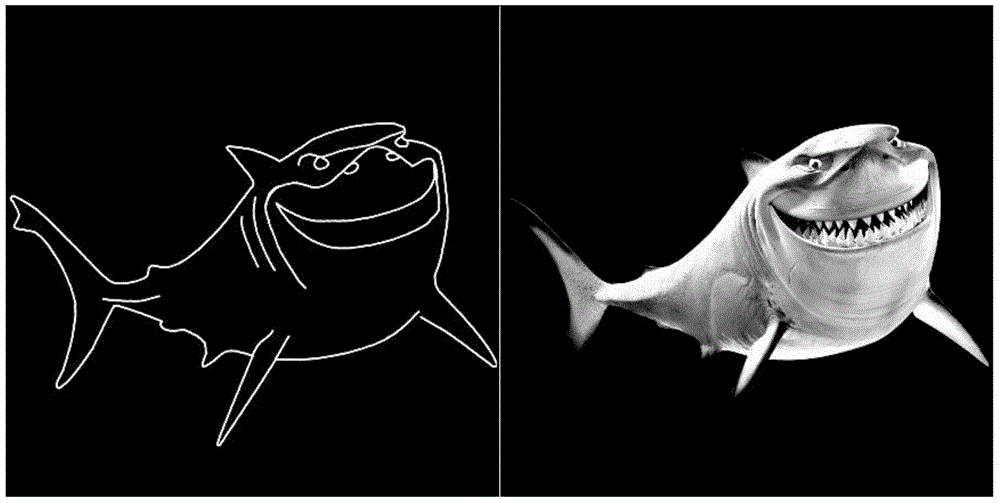

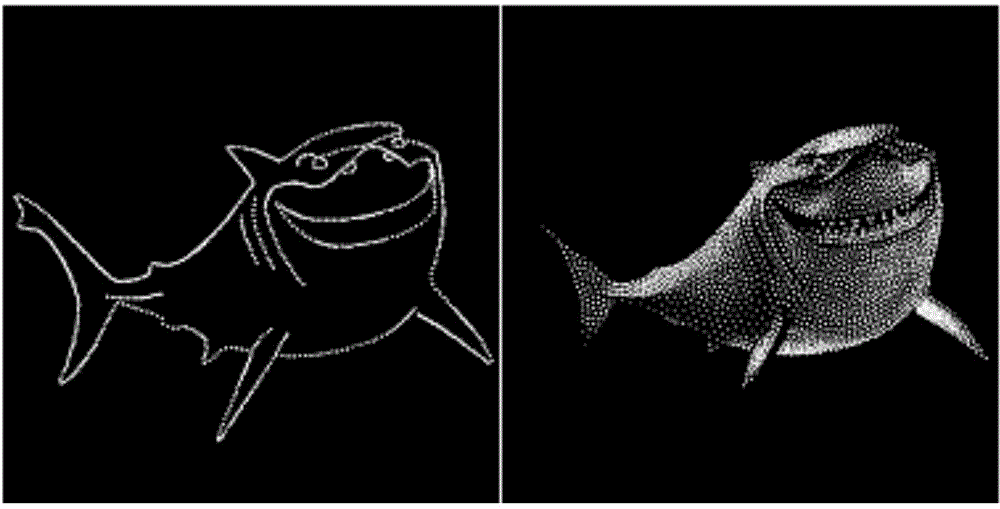

[0058] (2) For the input image I, generate a feature layer I that maintains the characteristics of the original image f and tint layer I r Two-layer image, calculate the corresponding halftone distribution, that is, feature layer I f The halftone distribution H f and tint layer I r The halftone distribution H r ,like Figure 1b shown.

[0059] (3) For halftone distribution H f and H r Every point p in i , under the printability constraint,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com