High pressure gas control device

A control device and high-pressure gas technology, which is applied in fire rescue and other directions, can solve problems such as unstable range, small cross-sectional area of gas transmission channels, and insufficient pressure, and achieve the effects of controlling stability, improving spray pressure and spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

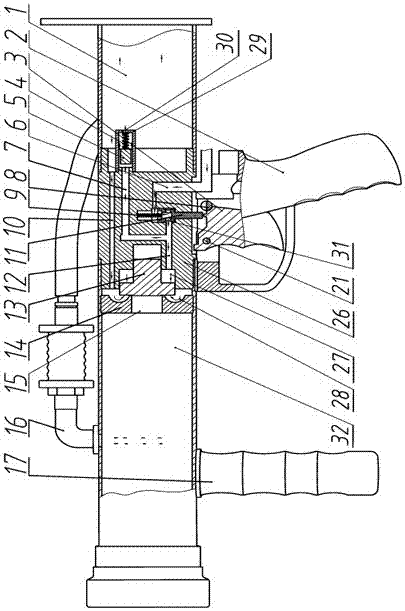

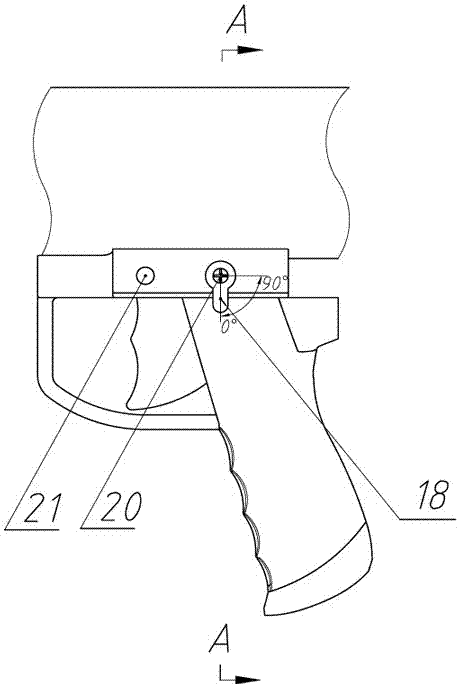

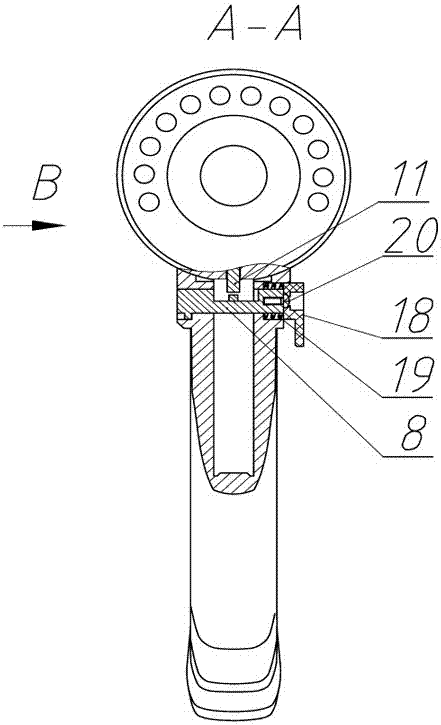

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the present invention includes a gas storage chamber 1, a nozzle 32 (water spray head 16), a handle [a front handle 17, a rear handle 2 (a boss 23, an opening groove 24, a locking groove 25)], Joystick 3, ventilation control parts (gas 26, compression spring 4, plug 5, channel 1 6, channel 2 7, channel 3 10, channel 4 12, control pin 8, return spring 9, return device 11, Tee pipe 31, plunger body 13, end cap 14, air chamber 28, air outlet 15, plunger chamber 27, sleeve 29, through hole 30), control pin 8 (positioning platform 22), rotary handle 18, fixed axis 21.

[0023] The water spray head 16 is positioned at the front end of the air outlet 15 .

[0024] The fixed shaft 21 is fixed on the rear handle 2, and the joystick 3 is rotated and installed on the fixed shaft 21; one end is provided with a control pin 8 of a positioning platform 22 and is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com