Windmill-tubular condensing-type demister and demisting method thereof

A condensing, mist eliminator technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large pressure drop and low mist removal efficiency of the mist eliminator, achieve small pressure drop and improve the removal of mist. The effect of fog efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

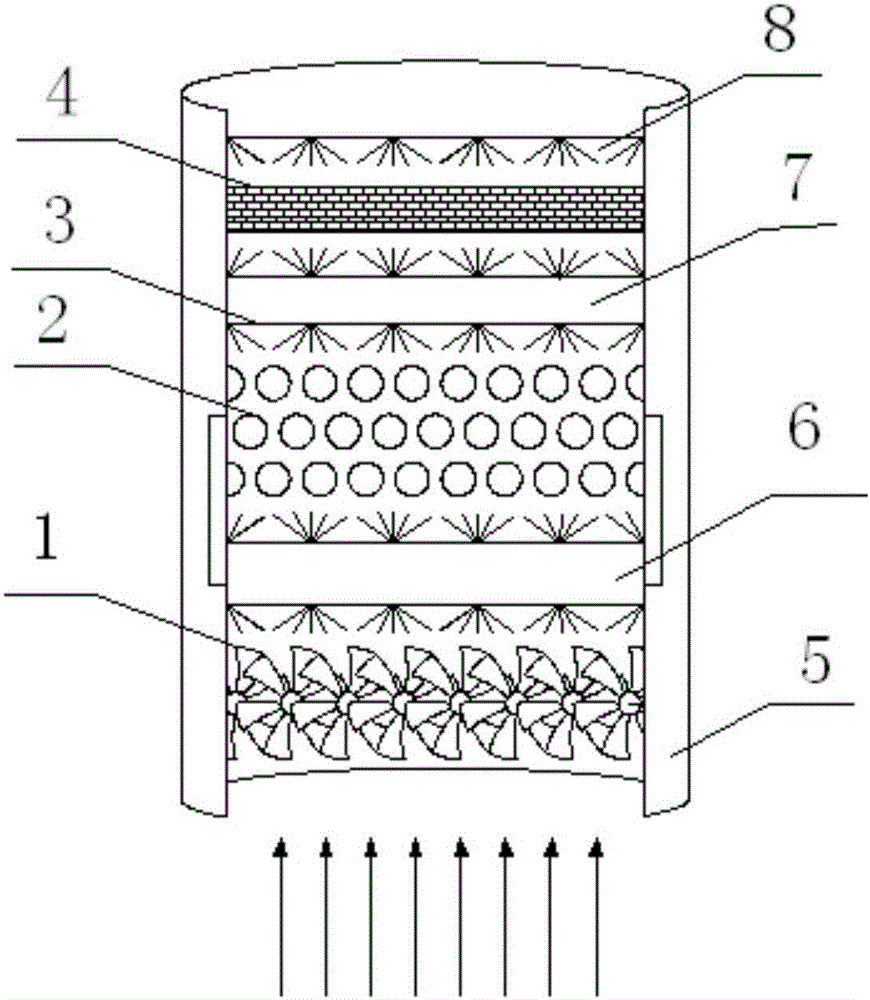

[0027] Such as figure 1 shown. A windmill-tubular condensing demister according to the present invention includes a housing 5, in which a windmill display defogging layer 1, a heat exchange tube array defogging layer 2, and a wire mesh are sequentially arranged at intervals from bottom to top. Demister layer 4;

[0028] Windmill display defogging layer 1 (the first stage) consists of multiple windmills connected in series and arranged side by side. The blades of each windmill have the same inclination direction and rotation direction, and the airflow spirals up from bottom to top and passes through the windmill display in order Layer 1, heat exchange tube array defogging layer 2, wire mesh defogging layer 4. There is a certain distance between the windmills. When the gas flows through the blade channel of the wind workshop, due to the deflection of the streamline, the large-diameter droplets will deviate from the direction of the airflow and hit the surface of the blade due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com