Low-carbon and high-efficiency nanometer zirconium silicate manufacturing method and device

A manufacturing method and high-efficiency technology, applied in grain processing, etc., can solve problems such as the inability to meet the high-efficiency and low-cost manufacturing of nano-zirconium silicate, achieve the effect of circular production and sales, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

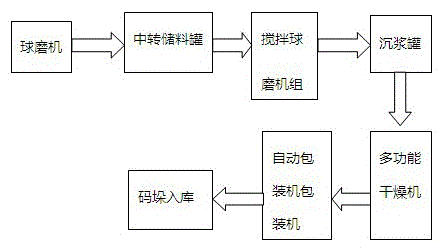

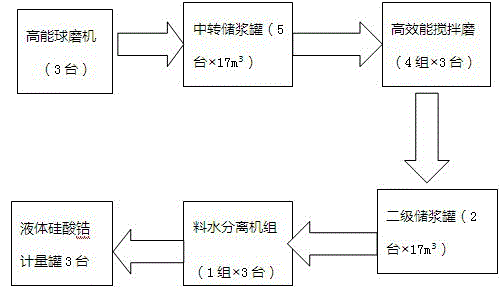

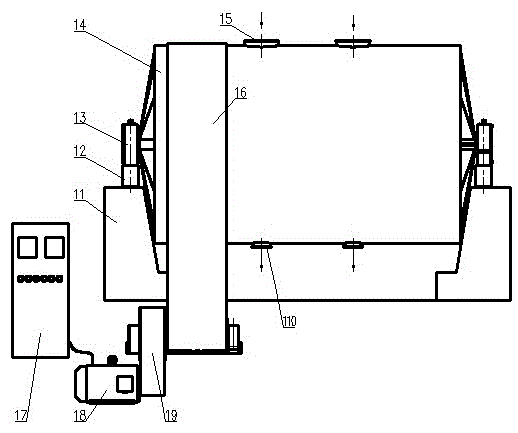

[0079] The following refer to the attached Figure 1-16 , a low-carbon and high-efficiency nano-zirconium silicate manufacturing method, comprising the following steps:

[0080] 1), select zircon sand;

[0081] 2) Processing procedure of high-energy drum type ultra-fine ball mill;

[0082] 3), transfer material process;

[0083] by 5 sets × 17m 3 It is composed of a stainless steel tank with a pneumatic stirring device at the bottom; it accepts incoming materials from the previous process for storage, and supplies stable slurry for the next process;

[0084] 4), high-efficiency stirring nanometer ball mill processing procedure;

[0085] 5), secondary slurry tank process:

[0086] By 2 × 17m 3 It is composed of a stainless steel tank with a pneumatic stirring device at the bottom, which is used to accept incoming materials from the previous process for storage and supply stable slurry for the next process;

[0087] 6), nanometer material slurry water separation process: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com