Liquid-plastic clamps for thin-walled bushings

A thin-walled shaft and fixture technology, applied in the direction of expanding the mandrel, etc., can solve the problems of loss of clamping effect of the fixture, decreased machining accuracy of parts, leakage of liquid plastic, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

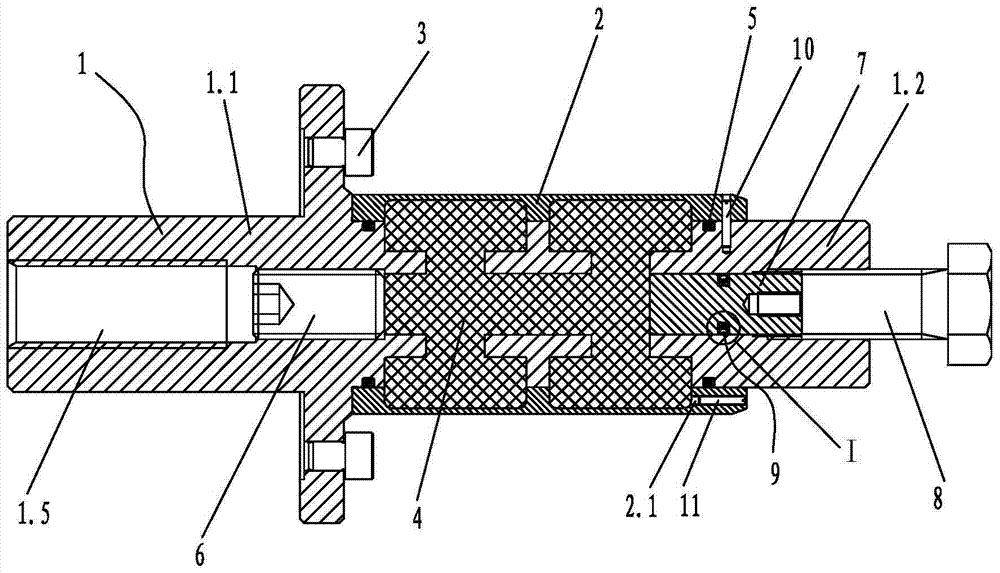

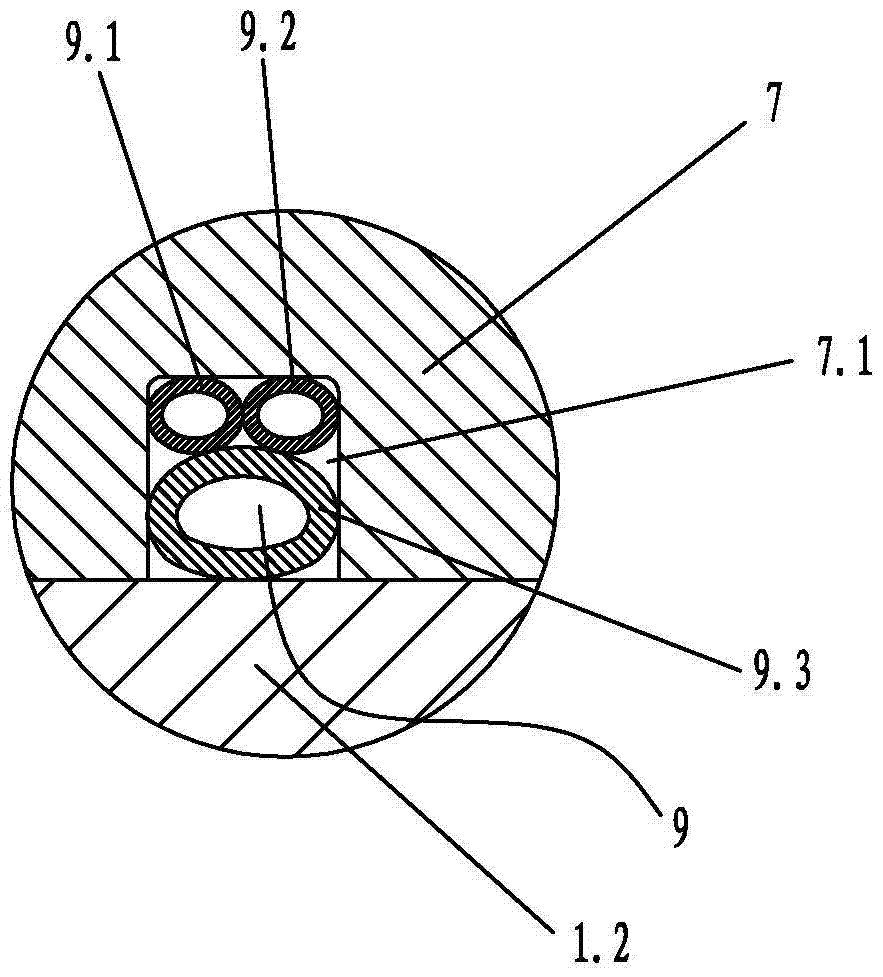

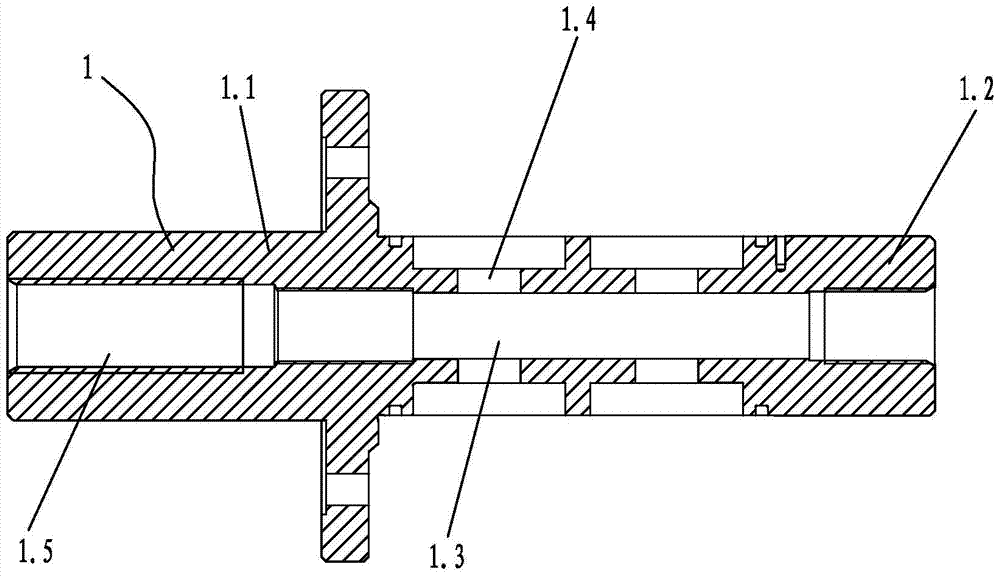

[0023] Such as Figure 1 ~ Figure 4 As shown, the special liquid-plastic fixture for thin-walled bushings includes fixture body 1, expansion sleeve 2 for tightening the inner hole of thin-walled bushing parts and support nail 3 for positioning the end face of thin-walled bushing parts , the clamp body 1 includes a connection part 1.1 and an expansion mandrel 1.2, a cavity 1.3 is provided inside the clamp body, the cavity 1.3 runs through the connection part 1.1 and the expansion mandrel 1.2, and the expansion mandrel 1.2 There are several radial through holes 1.4 communicating with the inner cavity 1.3; the expansion sleeve 2 is fixedly sleeved on the expansion mandrel 1.2, the cavity 1.3 is filled with liquid plastic 4, and the support The nails 3 are fixed on the clamp body 1 and three are evenly distributed in the axial direction relative to the central axis of the clamp body 1. The expansion mandrel 1.2 and the expansion sleeve 2 are sealed by a sealing ring 5, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com