A Friction Stir Welding Tool with Strong Interface Deformation and Adjustable Exploration Depth

A friction stir and adjustable technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as stirring head wear and weak connection, increase metallurgical bonding area, enhance plastic deformation and flow, and prevent wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

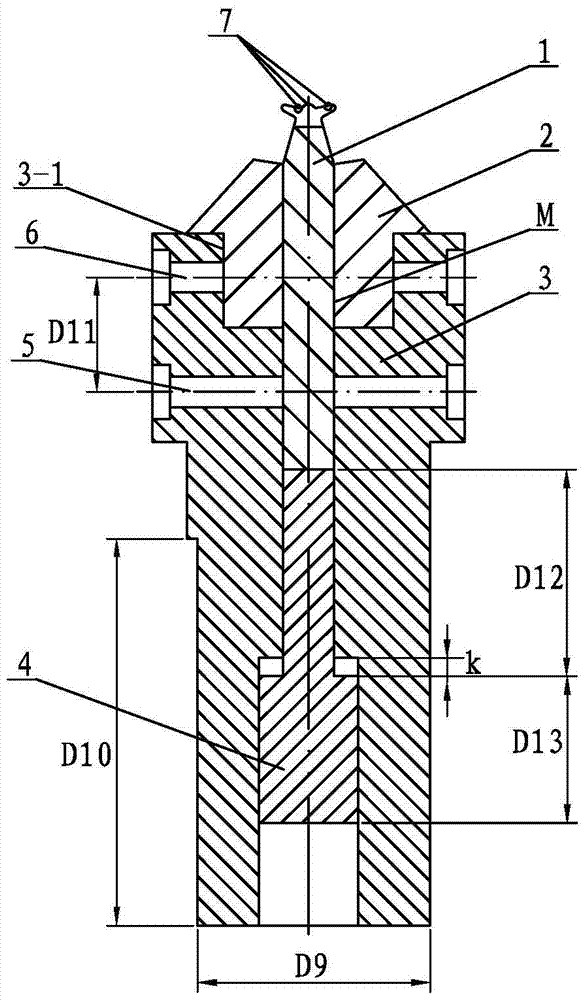

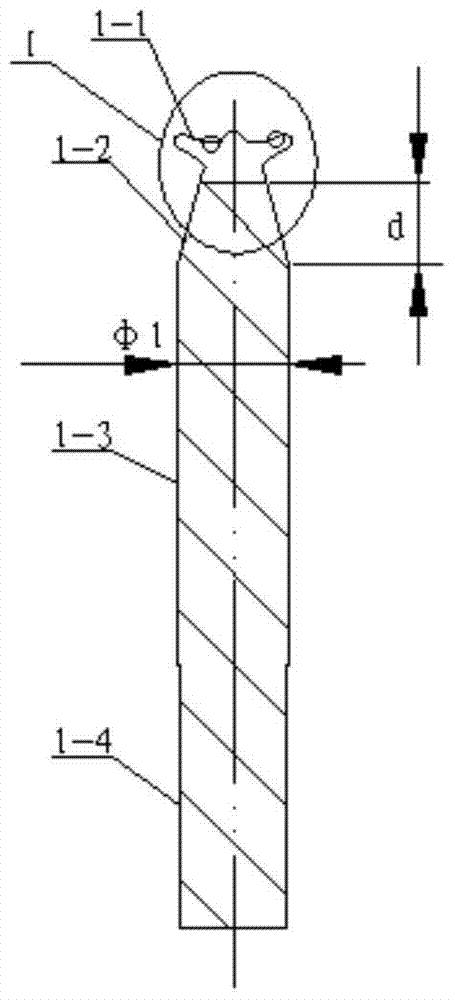

[0019] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, this embodiment includes a stirring needle 1, an adapter sleeve 2, a clamping handle 3, an adjusting bolt 4, a first fastening bolt 5 and a second fastening bolt 6, and the upper end surface of the clamping handle 3 is provided with The adapter sleeve installation groove 3-1, the adapter sleeve 2 is set in the adapter sleeve installation groove 3-1, the axis of the adapter sleeve 2 and the clamping handle 3 is provided with a stirring needle installation hole M, and the stirring needle 1 is set On the upper part of the stirring needle installation hole M, the adjusting bolt 4 is arranged at the lower part of the stirring needle installation hole M, the first fastening bolt 5 fastens the stirring needle 1 and the clamping handle 3, and the second fastening bolt 6 fastens the stirring needle 1 , the adapter sleeve 2 and the clamping handle 3 are fastened, and the stirring needle body...

specific Embodiment approach 2

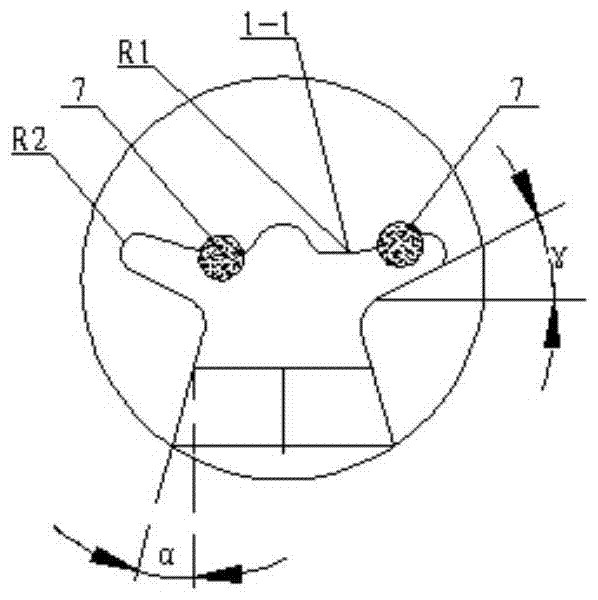

[0020] Specific implementation mode two: combination figure 2 with image 3 To illustrate this embodiment, the transition part between the concave end surface 1-1 and the stirring needle part 1-2 of this embodiment is a spherical surface or a plane processed with smooth chamfers. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination image 3 Describe this embodiment, the radius R1 of the concave end surface 1-1 of this embodiment is 1.2mm~2.4mm, the transition arc surface R2 is 0.2mm~0.5mm, the transition angle γ is 20°~30°, each concave The radius of the arc 1-1-1 is 2.0mm-3.5mm, and the central angle corresponding to the concave arc 1-1-1 is 25°-50°. The design of the three concave arcs 1-1-1 in the circumferential direction is conducive to endowing the flow of the interface plastic material with a dynamic and static combination mode, and providing a strong deformation effect for the interface material. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com