Injection molding preparation method for magnetic composite material in magnetostatic field

A magnetic composite material, injection molding technology, applied in the direction of magnetism of organic materials/organic magnetic materials, to achieve the effect of cost reduction and simplification of procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

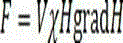

Method used

Image

Examples

Embodiment 1

[0029] Step 1) Raw material preparation

[0030] Add 5 parts of ferromagnetic Fe particles to 100 parts of polyethylene and mix evenly at 120°C;

[0031] Step 2) Injection molding in magnetic field

[0032] Inject the raw material into the mold under a certain pressure, the injection temperature is 140°C, apply a static magnetic field at the mold, and the magnetic field strength is 0.01T;

[0033] Step 3) Cooling and demoulding

[0034] After holding the pressure for a period of time, the plastic part is cooled to a certain temperature and the mold can be opened, and the plastic part is pushed out of the mold under the action of the ejection mechanism to obtain the product.

Embodiment 2

[0036] Step 1) Raw material preparation

[0037] Add 20 parts of ferromagnetic Co particles to 100 parts of polypropylene and mix evenly at 160°C;

[0038] Step 2) Injection molding in magnetic field

[0039] Inject the raw material into the mold under a certain pressure, the injection temperature is 180°C, apply a static magnetic field at the mold, and the magnetic field strength is 0.1T;

[0040] Step 3) Cooling and demoulding

[0041] After holding the pressure for a period of time, the plastic part is cooled to a certain temperature and the mold can be opened, and the plastic part is pushed out of the mold under the action of the ejection mechanism to obtain the product.

Embodiment 3

[0043] Step 1) Raw material preparation

[0044] Add 50 parts of ferromagnetic Ni particles to 100 parts of polystyrene and mix evenly at 180°C;

[0045] Step 2) Injection molding in magnetic field

[0046] Inject the raw material into the mold under a certain pressure, the injection temperature is 200°C, apply a static magnetic field at the mold, and the magnetic field strength is 0.5T;

[0047] Step 3) Cooling and demoulding

[0048] After holding the pressure for a period of time, the plastic part is cooled to a certain temperature and the mold can be opened, and the plastic part is pushed out of the mold under the action of the ejection mechanism to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com