Extrusion and preparation method of metal reinforced composite material in alternating magnetic field

An alternating magnetic field and extrusion molding technology is applied in the field of material preparation to achieve the effects of cost reduction and simplification of procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

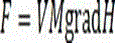

Method used

Image

Examples

Embodiment 1

[0025] 1) Mud preparation

[0026] Metal Cu with excellent conductivity and ZrO with high resistivity were mixed in the mud refining machine 2 Mix the powder, add organic solvent ethanol, dispersant herring oil and binder vinyl butyral, and mix evenly to obtain mud. The volume fraction of the organic solvent is 20% of the mud, the volume fraction of the dispersant is 0.2%, and the mass fraction of the adhesive is 10% of the mud;

[0027] 2) Extrusion molding in alternating magnetic field

[0028] Extrude the mud in the extruder, the extrusion pressure is 0.2MPa, an alternating magnetic field is applied at the extrusion port, the sample is located at the end of the alternating magnetic field coil, the current intensity is 0.1A, and the current frequency is 10 2 Hz, and then obtain the green body;

[0029] 3) Drying and sintering

[0030] After drying at 20°C, sintering is carried out in a protective environment of argon at a sintering temperature of 1200°C, kept for 4 hours...

Embodiment 2

[0032] 1) Mud preparation

[0033] In the mud refining machine, the metal Al with excellent conductivity and the Al with high resistivity 2 o 3 Mix the powder, add organic solvent methyl ethyl ketone, dispersant phosphate and binder polyvinyl alcohol, and mix evenly to obtain mud. The volume fraction of the organic solvent is 30% of the mud, the volume fraction of the dispersant is 1%, and the mass fraction of the adhesive is 15% of the mud;

[0034] 2) Extrusion molding in alternating magnetic field

[0035] Extrude the mud in the extruder, the extrusion pressure is 0.4MPa, an alternating magnetic field is applied at the extrusion port, the sample is located at the end of the alternating magnetic field coil, the current intensity is 0.5A, and the current frequency is 10 3 Hz, and then obtain the green body;

[0036] 3) Drying and sintering

[0037] After drying at 30°C, sintering is carried out in a nitrogen protective environment at a sintering temperature of 1300°C, ke...

Embodiment 3

[0039] 1) Mud preparation

[0040] In the mud refining machine, the metal Ag with excellent conductivity and SiO with high resistivity 2 Mix the powder, add organic solvent butanone, dispersant triolein and binder vinyl butyral, and mix evenly to obtain mud. The volume fraction of the organic solvent is 40% of the mud, the volume fraction of the dispersant is 2%, and the mass fraction of the adhesive is 20% of the mud;

[0041] 2) Extrusion molding in alternating magnetic field

[0042] Extrude the mud in the extruder, the extrusion pressure is 0.5MPa, an alternating magnetic field is applied at the extrusion port, the sample is located at the end of the alternating magnetic field coil, the current intensity is 1A, and the current frequency is 10 4 Hz, and then obtain the green body;

[0043] 3) Drying and sintering

[0044]After drying at 40°C, sintering is carried out in a nitrogen protective environment at a sintering temperature of 1400°C, kept for 4 hours, and then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com