A tire tread profiling winding method based on pixel method

A tire tread and pixel technology, applied in the field of tire manufacturing, can solve the problems of low tire yield, difficulty in controlling the shape and quality of the tire, the weight of the wrapped compound, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited.

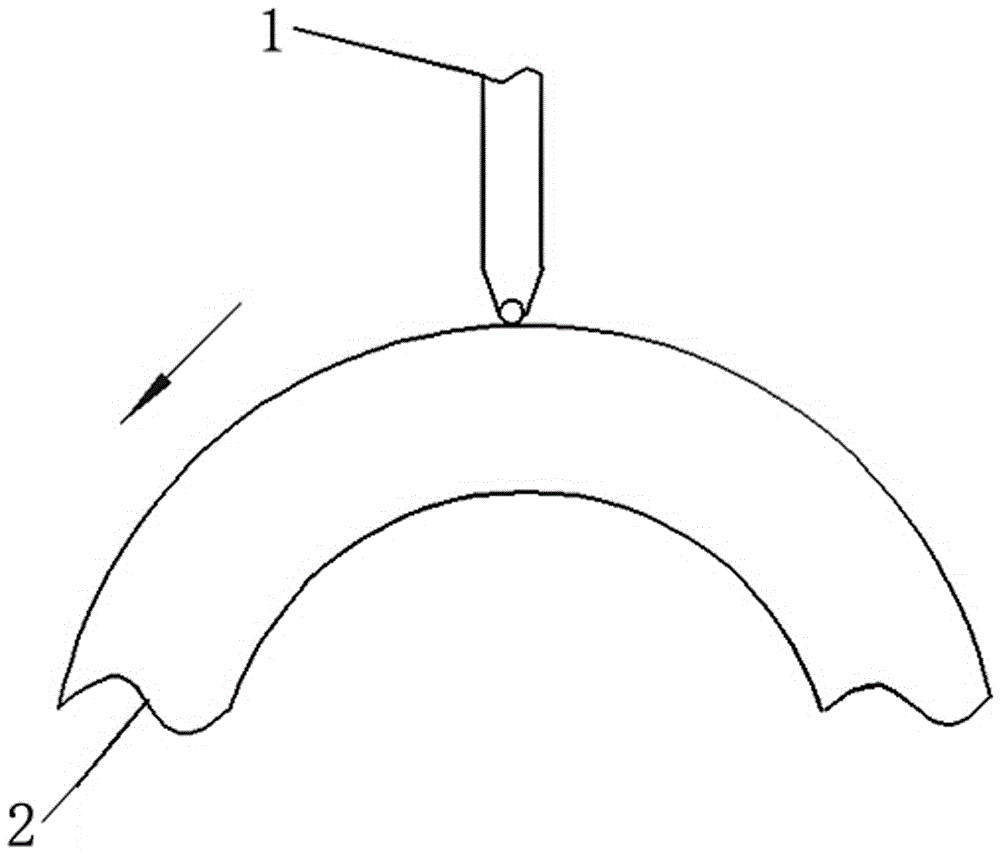

[0022] A tire tread profiling winding method based on the pixel method, comprising three steps: tread profiling winding based on the pixel method, shape control of the winding rubber strip, and open-loop profiling process control.

[0023] The specific steps of the tire tread profiling winding based on the pixel method are as follows:

[0024] (1) Establishment of space mapping of multi-dimensional coordinates of tire tread

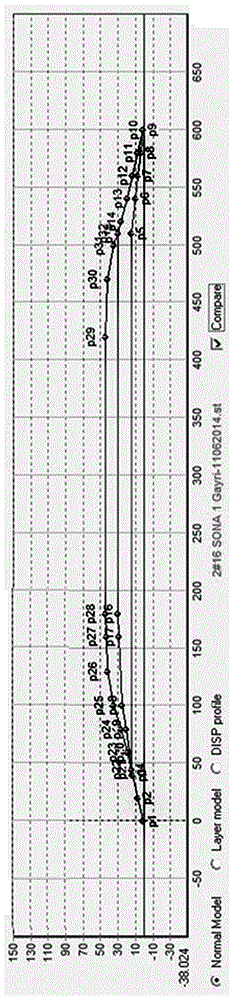

[0025] The shape of the tire tread is described in an object-oriented manner, and its structure is described by an array P: the array P consists of abscissa point L, ordinate point H, and abscissa point correction L m , ordinate point correction H m , the number of layers is composed of Layer, and the shape of the tread is obtained by inputting a group from P 1 (L 1 , H 1 , L m1 , H m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com