Ship seaworthiness tester

A tester and ship technology, applied in the testing of machine/structural parts, instruments, ship parts, etc., can solve problems such as not reflecting real motion, resistance measurement effects, spring elastic damping, etc., to achieve accurate positioning and ultra-low damping coefficient , the effect of reducing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

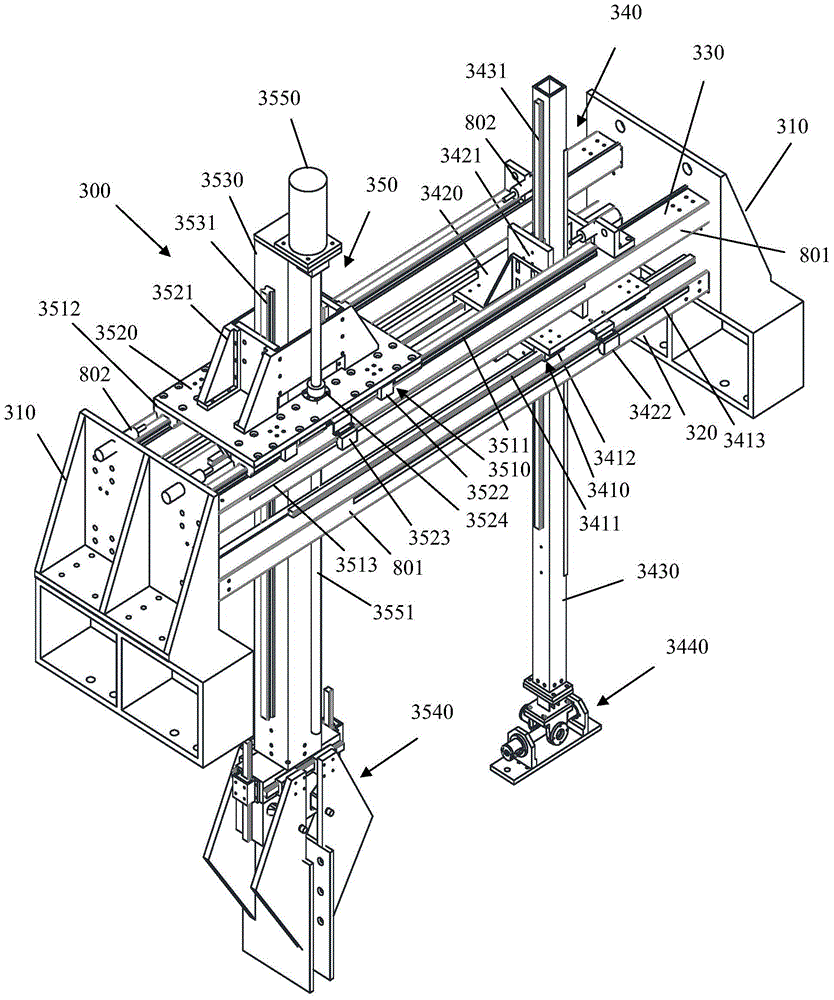

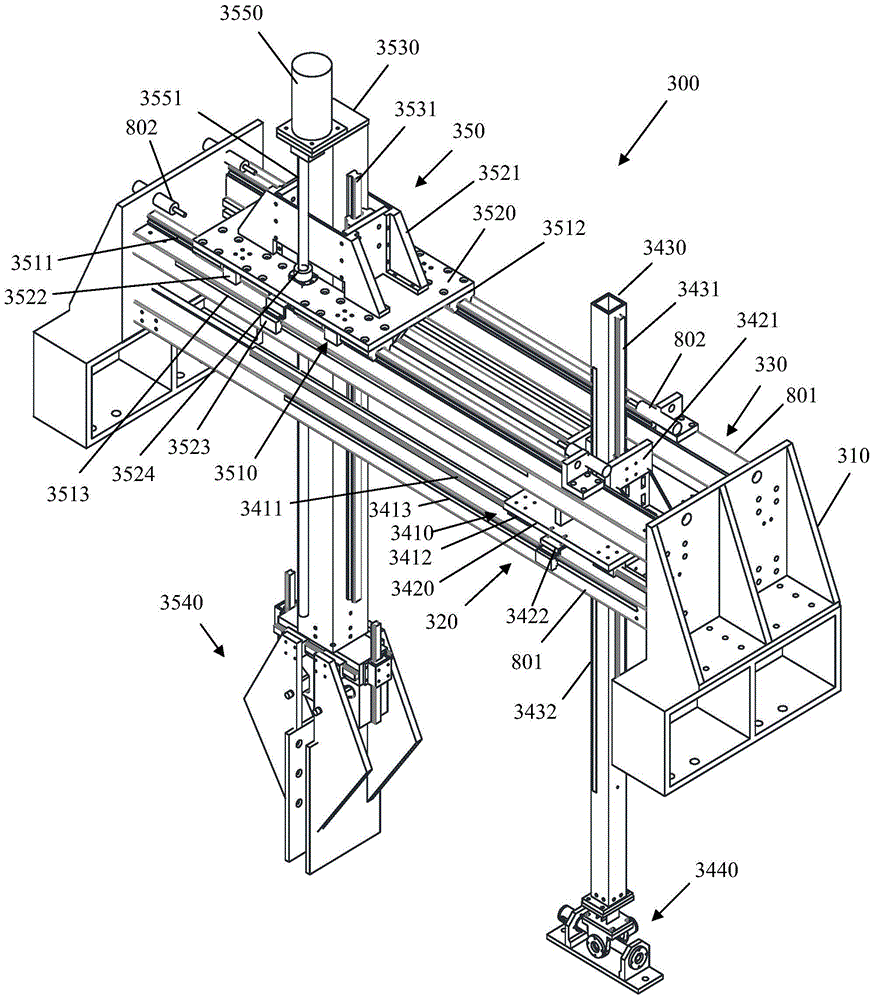

[0037] Such as figure 1 and figure 2 As shown, the ship seaworthiness tester 300 includes a pair of column frames 310 , a first beam frame 320 , a second beam frame 330 , a seaworthiness test device 340 and a following brake device 350 .

[0038] Wherein, a pair of column frames 310 are arranged on both sides, the first beam frame 320 and the second beam frame 330 are installed between the upper parts of the pair of column frames 310, the first beam frame 320 is located below the second beam frame 330, the first Both the beam frame 320 and the second beam frame 330 are composed of a pair of parallel and spaced beams 801 .

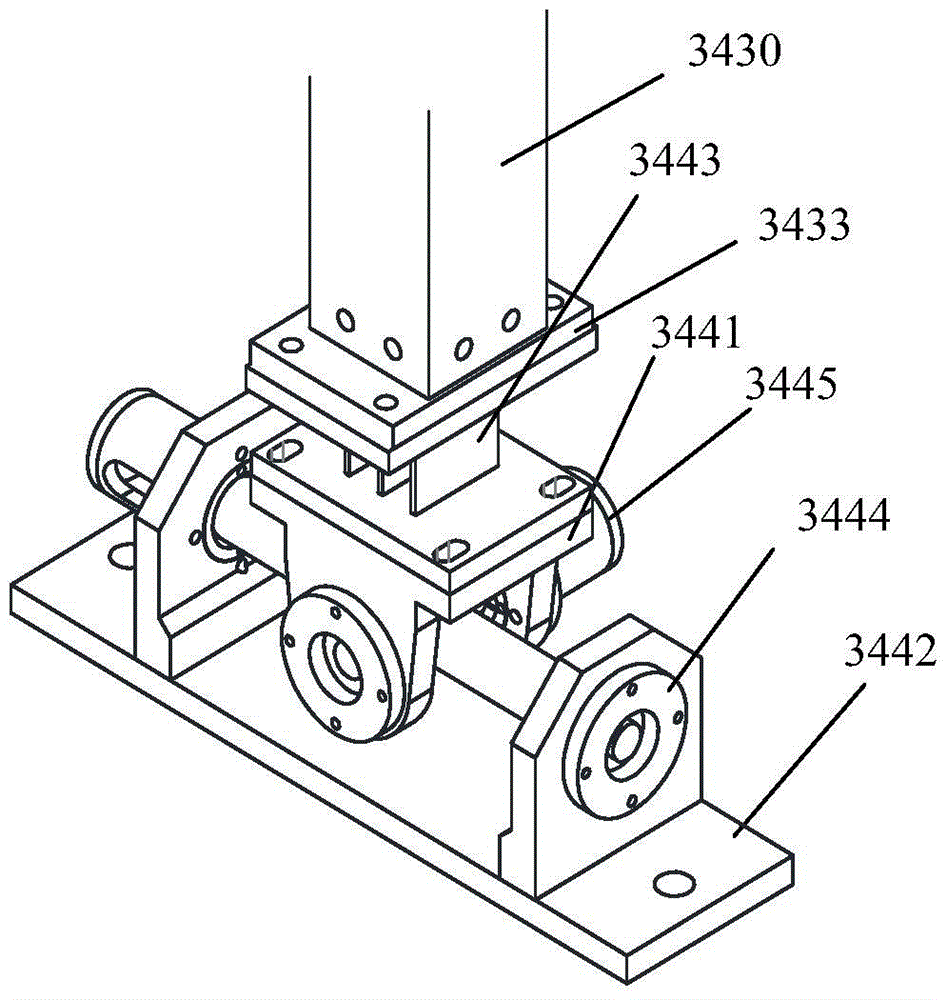

[0039] The airworthiness test device 340 includes a first linear motor 3410 , a first sliding seat 3420 , a first movable column 3430 and a test head 3440 .

[0040] The first linear motor 3410 is installed on the first beam frame 320 , and the first sliding seat 3420 is installed on the first linear motor 3410 . Driven by the first linear motor 3410 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com