A kind of corn glove based on 3D printing and preparation method thereof

A 3D printing and corn technology, applied in the field of textile materials, can solve problems such as monotonous styles, affecting performance, affecting the way and strength of the wearer's grip, and achieve the effect of improving grip strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

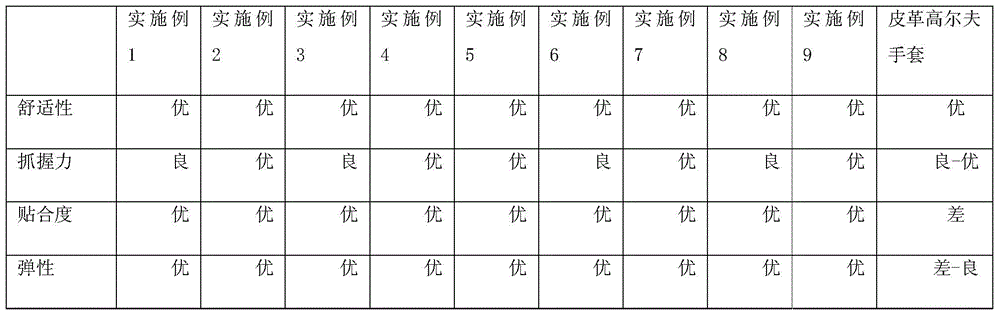

Examples

Embodiment 1

[0023] (1) Cut corn stalks into pieces, sieve, and grind to obtain corn fiber powder with a length of 0.1-0.3mm, add the corn fiber powder into a solvent, stir and let it stand for 4 hours, after the corn fiber is fully swollen, add a starter, Mix evenly, high-temperature fermentation, hydrolysis, purification and polycondensation to obtain a polylactic acid high polymer with a viscosity of 280mPas.

[0024] (2) Transfer the polylactic acid polymer to the 3D printing device, adjust the orientation of the 3D printing according to the analysis and added hand data, and extrude the polylactic acid polymer from the port at 190°C at a speed of 0.6m / s Then, an integrated corn glove is formed on the three-dimensional receiver covered with a layer of conductive material.

[0025] (3) The corn glove was trimmed and cured at 110°C for 30 minutes to obtain a 3D printed corn glove with a thickness of 3 mm and a micro-nano structure on the surface.

Embodiment 2

[0027] (1) Shred, sieve, and grind corn stalks to obtain corn fiber powder with a length of 0.1-0.3mm, add the corn fiber powder to a solvent, stir and let stand for 6 hours, after the corn fiber is fully swollen, add a starter, Mix evenly, high-temperature fermentation, hydrolysis, purification and polycondensation to obtain a polylactic acid high polymer with a viscosity of 460mPas.

[0028] (2) Transfer the polylactic acid polymer to the 3D printing device, adjust the orientation of the 3D printing according to the analysis and added hand data, and extrude the polylactic acid polymer from the port at 220°C at a speed of 0.9m / s Then, an integrated corn glove is formed on the three-dimensional receiver covered with a layer of conductive material.

[0029] (3) The corn glove was trimmed, cured at 110°C for 60 min and other post-treatments to obtain a 3D printed corn glove with a thickness of 5 mm and a surface containing micro-nano-scale structures.

Embodiment 3

[0031] (1) Cut corn stalks into pieces, sieve, and grind to obtain corn fiber powder with a length of 0.1-0.3mm, add the corn fiber powder into a solvent, stir and let it stand for 4 hours, after the corn fiber is fully swollen, add a starter, Mix evenly, high-temperature fermentation, hydrolysis, purification and polycondensation to obtain a polylactic acid high polymer with a viscosity of 360mPas.

[0032] (2) Transfer the polylactic acid polymer to the 3D printing device, adjust the orientation of the 3D printing according to the analysis and added hand data, and extrude the polylactic acid polymer from the port at 200°C at a speed of 0.75m / s Then, an integrated corn glove is formed on the three-dimensional receiver covered with a layer of conductive material.

[0033] (3) The corn glove was trimmed and cured at 110°C for 50 minutes to obtain a 3D printed corn glove with a thickness of 3.6 mm and a micro-nano-scale structure on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com