Hatch coaming operating platform

A working platform and hatch coaming technology, which is applied to slipways, ship parts, ships, etc., can solve problems such as hidden safety hazards, manpower consumption, material resources, and operational difficulties, and achieve the effects of improving safety, reducing manpower, and being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

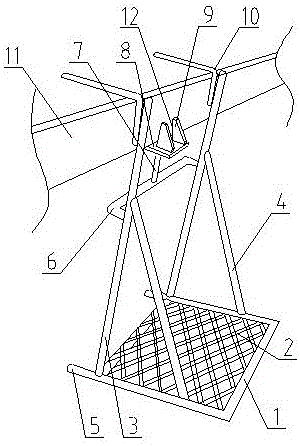

[0025] see figure 1 , a kind of hatch coam work platform of the present invention, it comprises square frame 1, and described square frame 1 is provided with support steel mesh 2, and described square frame 1 is provided with vertical support bar 3 on left and right two corners inside, and described A support rail 6 is arranged between the middle parts of the left and right vertical support rods 3, and the support rail 6 is provided with a connecting rod 7, and the top of the connecting rod 7 is provided with a fixed plate 8, and the left and right bars are arranged on the fixed plate 8. Two clamping boards 9 are provided with a clamping slot 12, and an L-shaped hanging rod 10 is provided on the top of the vertical support rod 3.

[0026] An oblique support rod 4 is arranged between the vertical support rod 3 and the square frame 1 .

[0027] The square frame 1 is provided with two left and right legs 5 inwardly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com