Drilling fluid and use of imidazole ionic liquid therein

A technology of ionic liquids and drilling fluids, applied in the field of drilling fluids, can solve problems such as difficult adjustment and control, failure of drilling operations, and reduced ability to carry cuttings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

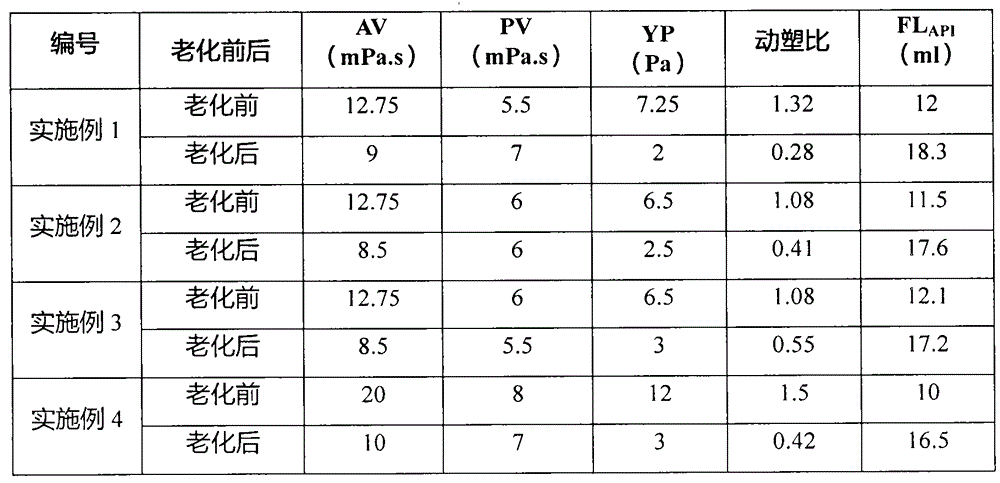

Embodiment 1

[0021] Drilling fluids containing ionic liquids comprising the following components:

[0022] 1-Butyl-3-methylimidazolium tetrafluoroborate 0.02% by weight

[0023] Partially hydrolyzed polyacrylamide 0.2% by weight

[0024] Sodium bentonite 4% by weight

[0025] The remainder of the aqueous solution.

[0026] First configure 10L drilling fluid with 4% bentonite, and pre-hydrate for 24 hours; at the same time, make the polymer into a glue solution with a certain concentration of 2%, and add the pre-hydrated drilling fluid according to the above ratio; measure the normal temperature (that is, before aging) Rheology and rheology after rolling at 160°C for 16 hours (that is, after aging); add the ionic liquid according to the above ratio, and measure the rheology at room temperature (that is, before aging) and the rheology after rolling at 160°C for 16 hours (that is, after aging). For comparison, see Table 1 for specific data.

Embodiment 2

[0028] The composition and preparation method of the drilling fluid are the same as in Example 1, except that the amount of 1-butyl-3-methylimidazolium tetrafluoroborate is changed to 0.05% by weight.

Embodiment 3

[0030] The composition and preparation method of the drilling fluid are the same as in Example 1, except that the amount of 1-butyl-3-methylimidazolium tetrafluoroborate is changed to 0.08% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com