Star polymer for drilling fluid and preparation method of star polymer

A star-shaped polymer and drilling fluid technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of decreased fluid loss reduction effect of drilling fluid, changes in rheological properties of drilling fluid, and abnormal drilling work, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

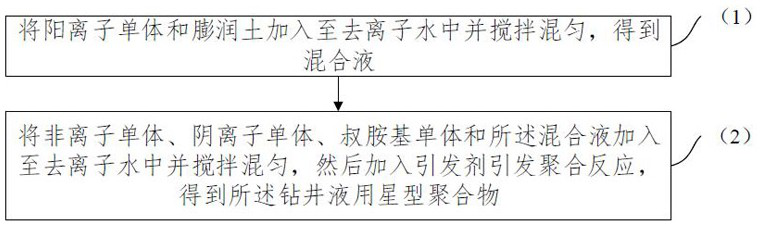

[0033] Such as figure 1 Shown, the invention provides a kind of preparation method of drilling fluid star polymer, and this preparation method comprises the steps:

[0034] (1) Add cationic monomer and bentonite to deionized water and stir to obtain a mixed solution;

[0035] (2) Add nonionic monomers, anionic monomers, tertiary amino monomers and the mixed solution into deionized water, stir and mix well, then add an initiator to initiate the polymerization reaction, and obtain the star polymerization for the drilling fluid things.

[0036] In a preferred embodiment, in step (1), cationic monomer and bentonite are added to deionized water and heated at 20-30°C (for example, 20°C, 22°C, 25°C, 28°C or 30°C) Stir and mix to obtain a mixed solution;

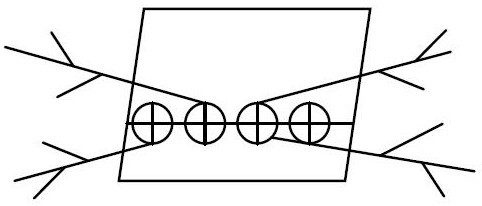

[0037] In the present invention, a two-step method is adopted, first cationic monomers are inserted into the layered structure of bentonite by ion exchange to obtain the core structure of the star-shaped polymer, so as to provide...

Embodiment 1

[0074] (1) Add 30g of cationic monomer (methacryloyloxyethyltrimethylammonium chloride) and 10g of bentonite (sodium bentonite) into 60g of deionized water and stir at 25°C for 2 hours to obtain a mixed solution ;

[0075] (2) Mix 200g of nonionic monomer (methacrylamide), 100g of anionic monomer (2-acrylamido-2-methylpropanesulfonic acid), 20g of tertiary amino monomer (dimethylaminomethacrylate) ethyl ester) and 100g of the mixed solution obtained in step (1) were added to 580g of deionized water and stirred to obtain a reaction solution, the temperature of the reaction solution was adjusted to 10°C, and the pH of the reaction solution was adjusted to The value is adjusted to 6.5, then feed nitrogen for 30min, then add initiator to initiate polymerization and react for 4h to obtain the star-shaped polymer for drilling fluid;

[0076] Wherein, the initiator includes 0.035g oxidizing agent (potassium persulfate), 0.035g reducing agent (sodium bisulfite), 0.05g complexing agen...

Embodiment 2

[0078] (1) Add 30g of cationic monomer (methacryloyloxyethyltrimethylammonium chloride) and 10g of bentonite (sodium bentonite) into 60g of deionized water and stir at 25°C for 2 hours to obtain a mixed solution ;

[0079] (2) Mix 220g of nonionic monomer (methacrylamide), 80g of anionic monomer (2-acrylamido-2-methylpropanesulfonic acid), 20g of tertiary amino monomer (dimethylaminomethacrylate) ethyl ester) and 100g of the mixed solution obtained in step (1) were added to 580g of deionized water and stirred to obtain a reaction solution, the temperature of the reaction solution was adjusted to 10°C, and the pH of the reaction solution was adjusted to The value is adjusted to 6.6, then feed nitrogen for 20 minutes, then add an initiator to initiate polymerization and react for 5 hours to obtain the star-shaped polymer for drilling fluid;

[0080]Wherein, the initiator includes 0.035g oxidizing agent (potassium persulfate), 0.035g reducing agent (sodium bisulfite), 0.05g comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com