Polymer latex coagulant for oil-absorbing swelling of cement-based materials

A cement-based material and polymer glue technology, applied in the field of petroleum exploration, can solve the problems of strong retardation and gelation, and achieve the effects of good high temperature dispersion, early strength improvement, and high temperature rheology improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

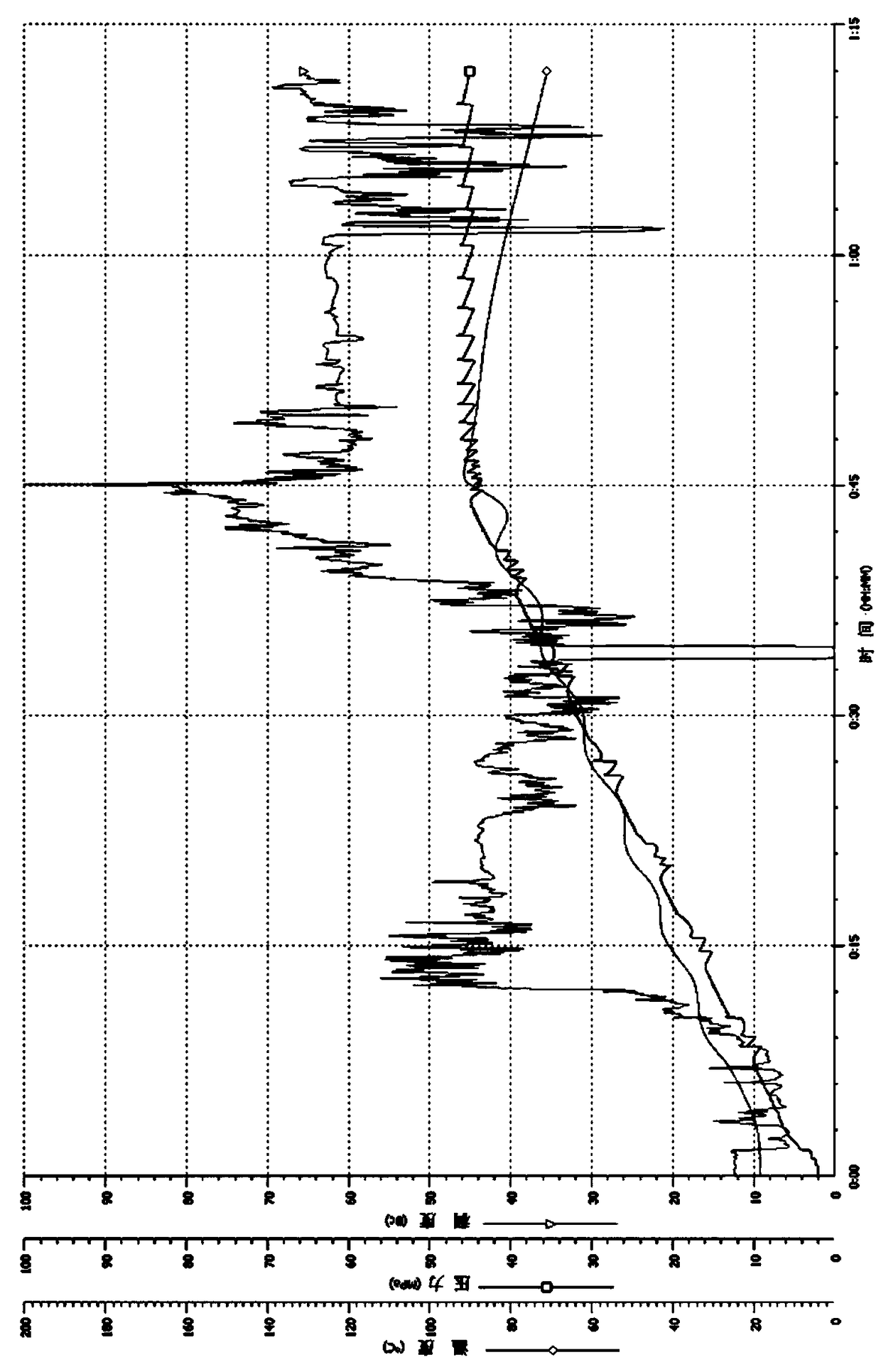

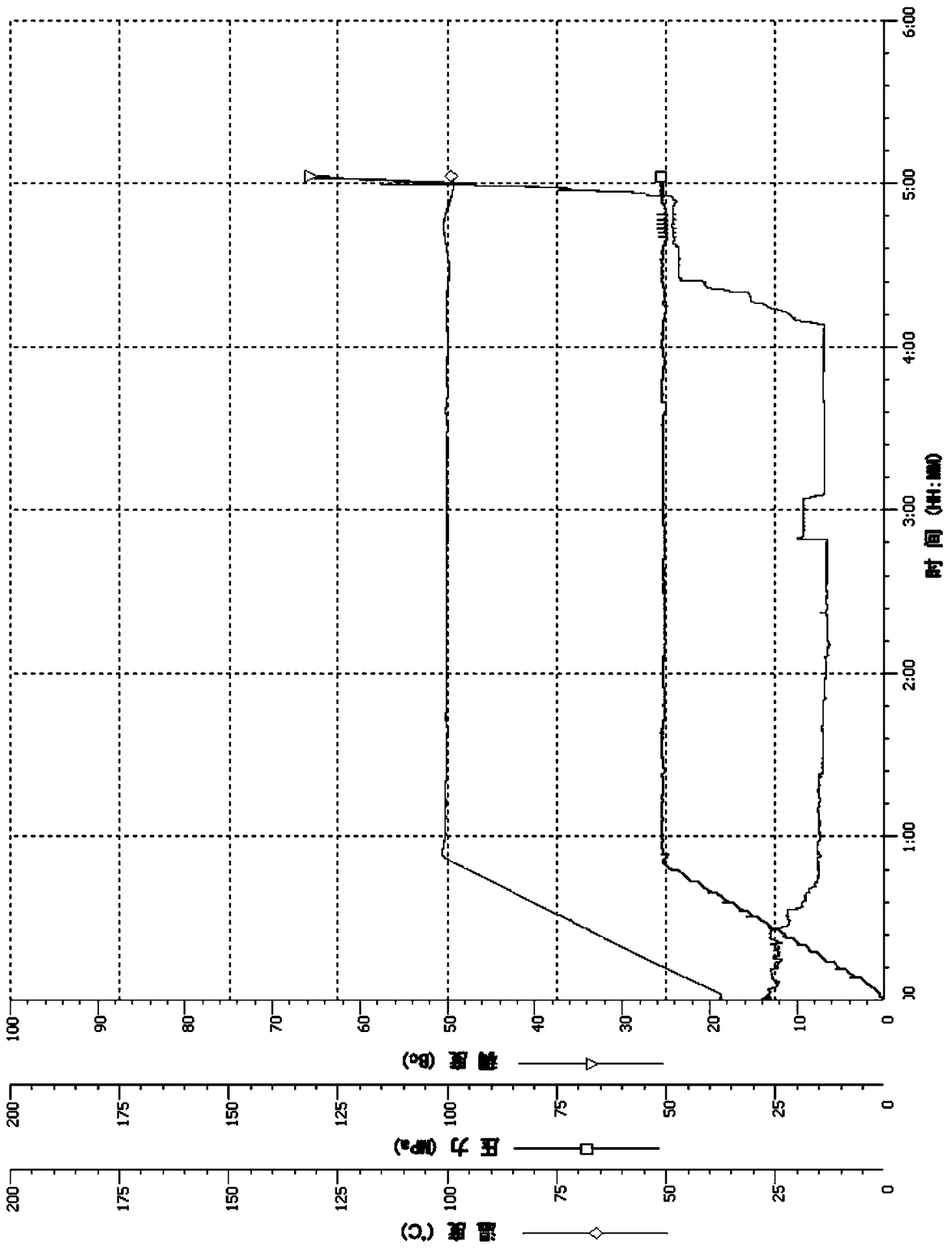

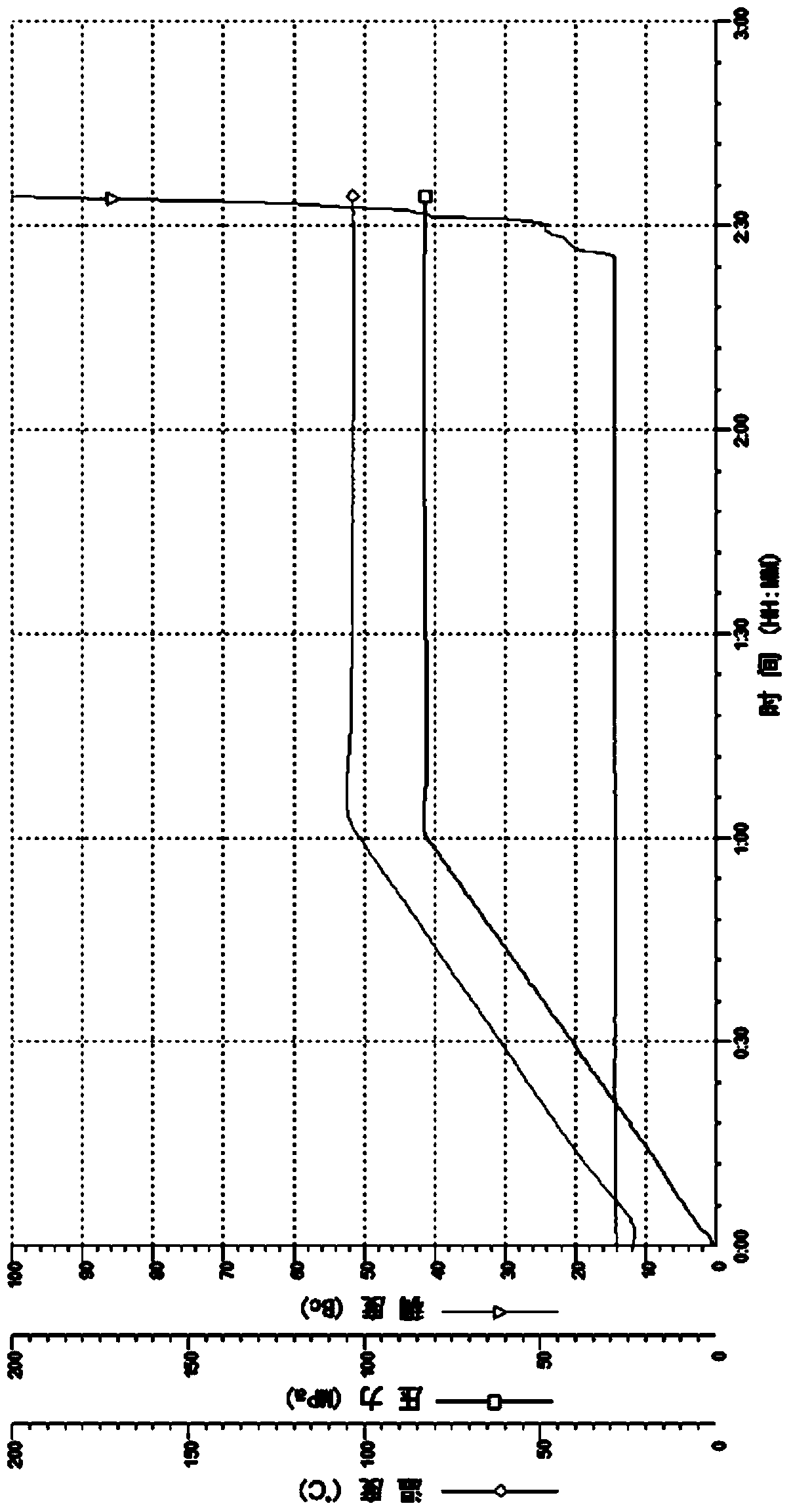

Image

Examples

Embodiment 1

[0041] In 286g water, add 64g acrylate polymer latex (the molar ratio of its polymerization monomer methacrylic acid, butyl methacrylate, hexadecyl methacrylate and styrene is 6:48:12:115), 2.4 g of citric acid and 0.8 g of diethanolamine were stirred evenly, and 800 g of grade G oil well cement was added thereto, and stirred evenly at a uniform speed to obtain polymer latex cement slurry.

Embodiment 2

[0043] In 270g water, add 80g of acrylic acid ester polymer latex and its polymerization monomer (the mol ratio of its polymerization monomer acrylic acid, hexyl methacrylate and styrene is 5:92:115), 4g tartaric acid, triethanolamine 1.2g, stir Evenly, add 800g of G-grade oil well cement into it, and stir at a uniform speed to obtain polymer latex cement slurry.

Embodiment 3

[0045] Add 80g of acrylic acid ester polymer latex in 270g of water (the molar ratio of its polymerization monomer methacrylic acid, butyl methacrylate, hexadecyl methacrylate and styrene is 6:67:19:115), 4.8 g of gluconic acid and 1.6 g of triethanolamine were stirred evenly, and 800 g of grade G oil well cement was added thereto, and stirred evenly at a uniform speed to obtain polymer latex cement slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com