Equipment and method for double-sided friction stir processing ultra-fine grain plate

A friction stir and ultra-fine grain technology, applied in the field of double-sided friction stir processing ultra-fine grain plate equipment, can solve the problems of reducing the mechanical properties of ultra-fine grain plates, weak mechanical properties, coarse structure, etc. Heat-affected zone, avoid weak areas of mechanical properties, and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

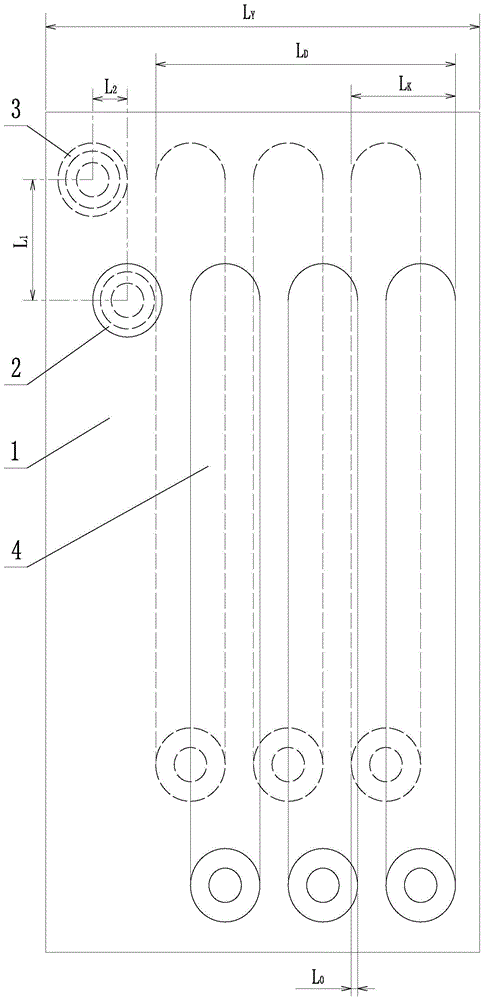

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] In this embodiment, the original plate 1 to be processed is a 7050 aluminum alloy plate with a thickness of 6.5 mm, and an ultrafine-grained aluminum alloy plate is to be prepared.

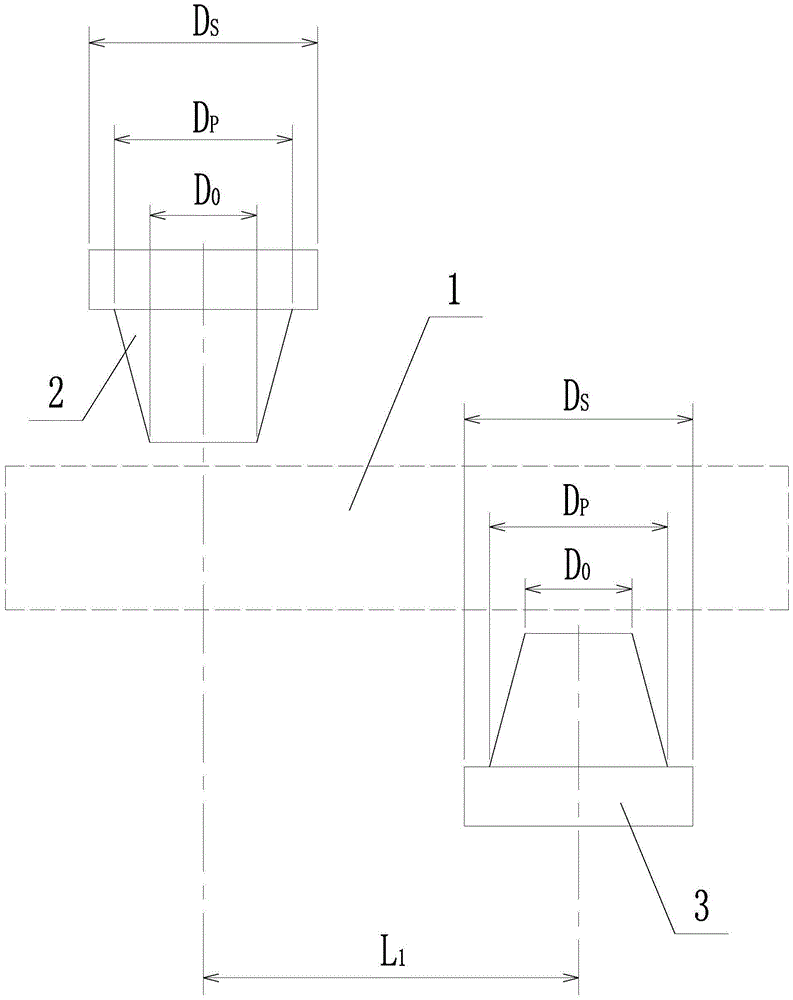

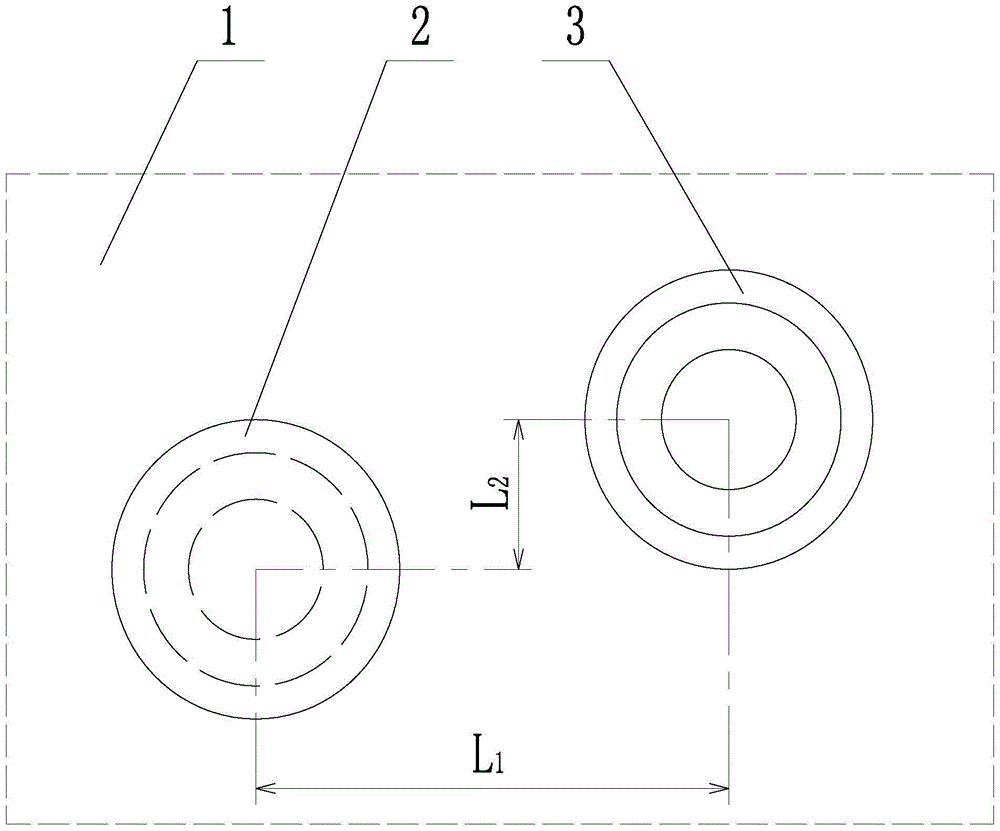

[0037] A double-sided friction stir processing ultra-fine-grain plate equipment, including two stirring heads, one stirring head is set as the positive stirring head 2, and the other stirring head is set as the reverse stirring head 3, the positive stirring head 2 and the reverse stirring head 3 have the same size and specifications, and are all composed of a shaft shoulder and a stirring needle. In this embodiment, the specific parameters of the stirring head are: the diameter of the shaft shoulder is 15mm, the diameter of the end of the stirring needle is 4.5mm, and the diameter of the root of the stirring needle is 6.5mm; The positive stirring h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com