Protection rubber strip of groove rail flangeway

A technology of rim grooves and grooved rails, applied in the direction of tracks, track superstructures, roads, etc., can solve the problems of failure to follow up the protective measures in time, unable to clean up in time, traffic accidents, etc., to reduce the amount of wear and tear and easy installation , the effect of strong fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

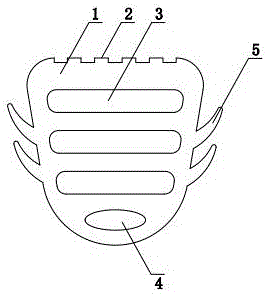

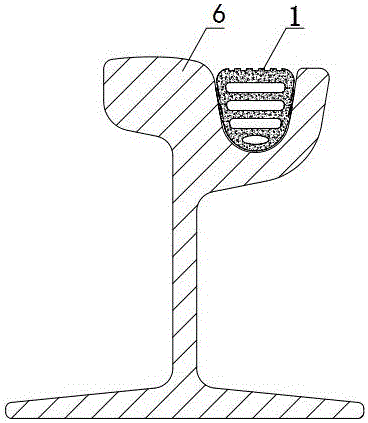

[0020] Such as figure 1 with figure 2 As shown, the protective rubber strip for the rim groove of the grooved rail in this embodiment is an integrally formed piece of rubber material, including the main body of the rubber strip 1, and the rubber strip body 1 can just be embedded in the rim groove of the grooved rail 6, and the rubber strip The upper surface of the body 1 is provided with a number of parallel protrusions 2 along the length direction of the rubber strip, and a number of oblong holes 3 and elliptical holes 4 are vertically formed inside the rubber strip body 1, and two are arranged on each side of the rubber strip body 1. The wing edge 5, the two wing edges 5 on either side are arranged up and down, the water accumulation diversion groove is formed between the wing edge 5 and the rubber strip body 1, and the outer surfaces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com