Power transmission tower angle steel connection joint

A technology for connecting nodes and transmission towers, which is applied to towers, building types, buildings, etc., can solve the problems of increasing the cost of towers and waste of steel materials, and achieve the effects of improving the ability to resist disaster weather, reducing tower weight, and improving the level of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

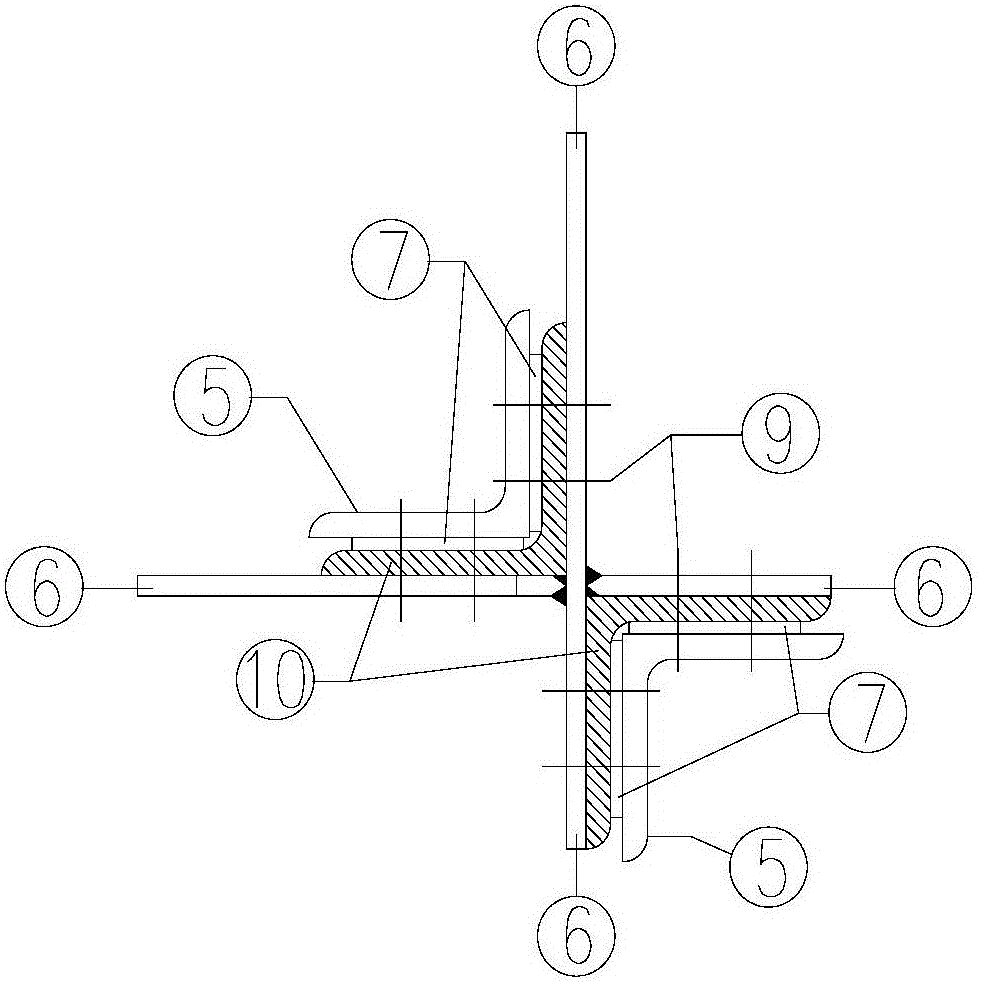

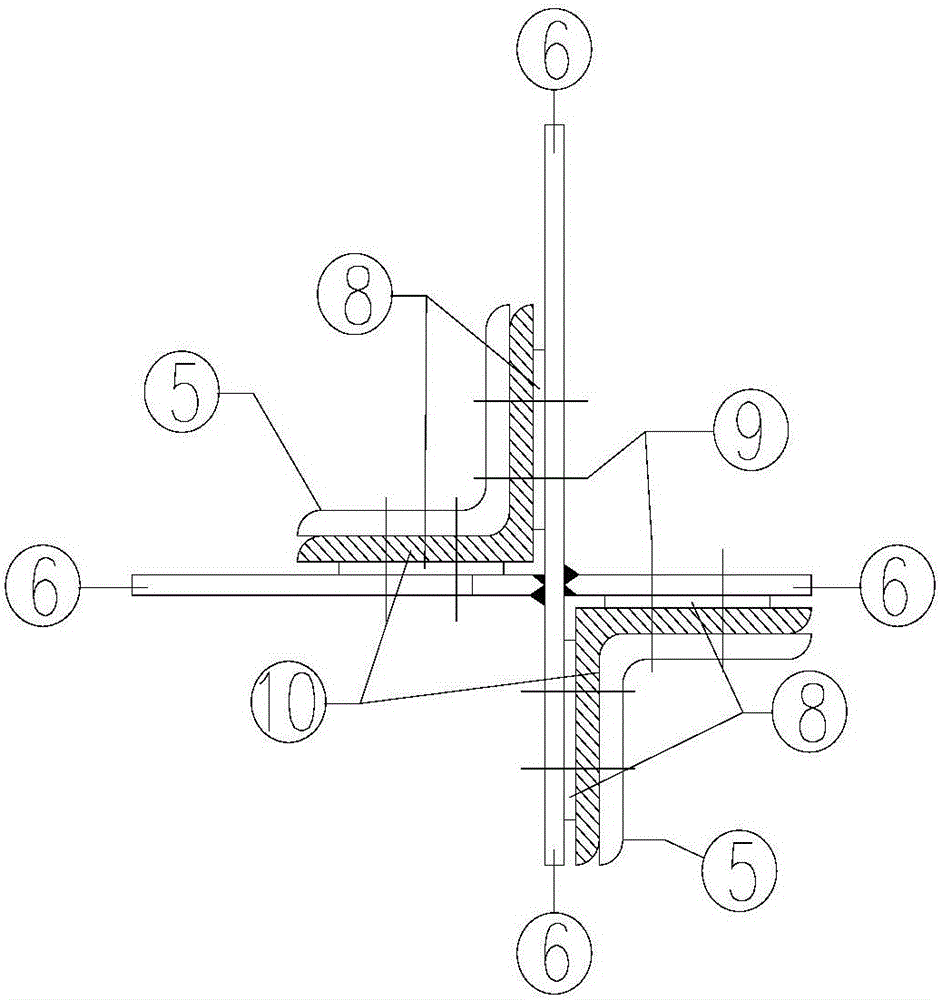

[0027] The invention proposes a main material connection structure aiming at the characteristics of gradual change in thickness of the cross-combined angle steel fill plate of the transmission iron tower.

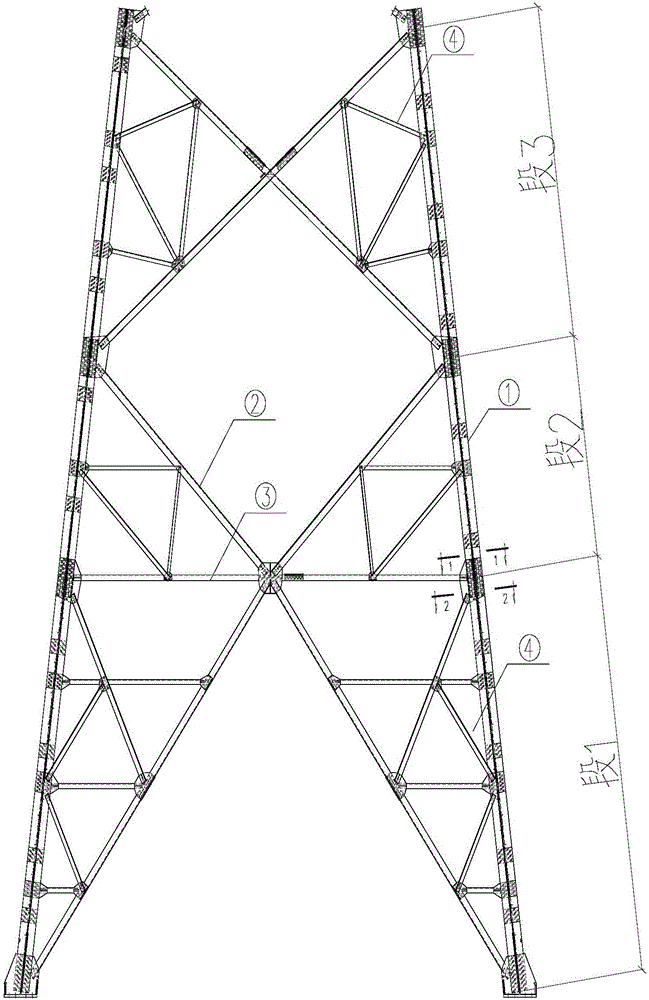

[0028] The front layout of the cross combination angle steel transmission tower is as attached figure 1 As shown, it is composed of main material 1, inclined material 2, transverse partition material 3 and auxiliary material 4, and the components are connected by connecting plates or connecting plate bolts. Among them, the main material 1 as the tower column arranged in the vertical direction, the oblique material 2 connected to the adjacent two main materials 1 with an angle of less than 90° with the horizontal direction, and the horizontal direction between the two main materials 1 are arranged The horizontal partition material 3 and the auxiliary material 4 connected with the main material 1, the horizontal partition material 3 and / or the oblique material 2.

[0029] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com