A waterway control valve structure

A waterway control valve, valve core technology, applied in valve details, diaphragm valves, valve devices, etc., can solve problems such as poor applicability, inappropriate solenoid valves, and valve diaphragms are easily damaged, and achieve reasonable structural design and avoid water hammer. Vibration, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

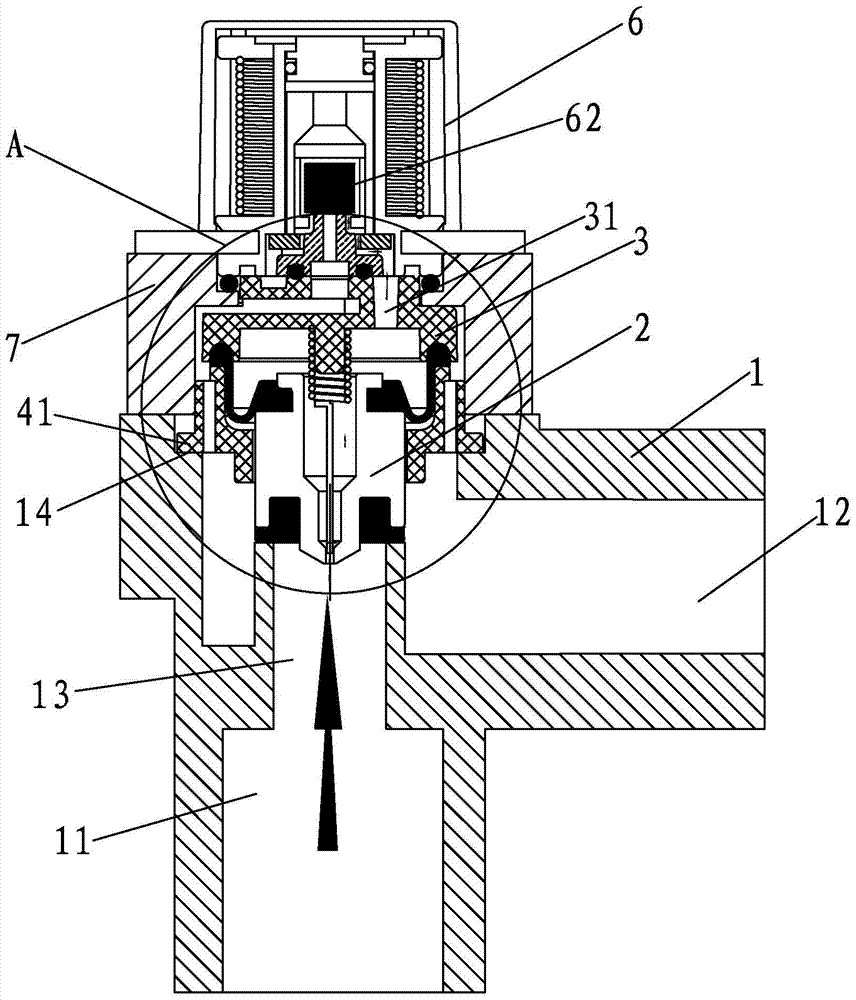

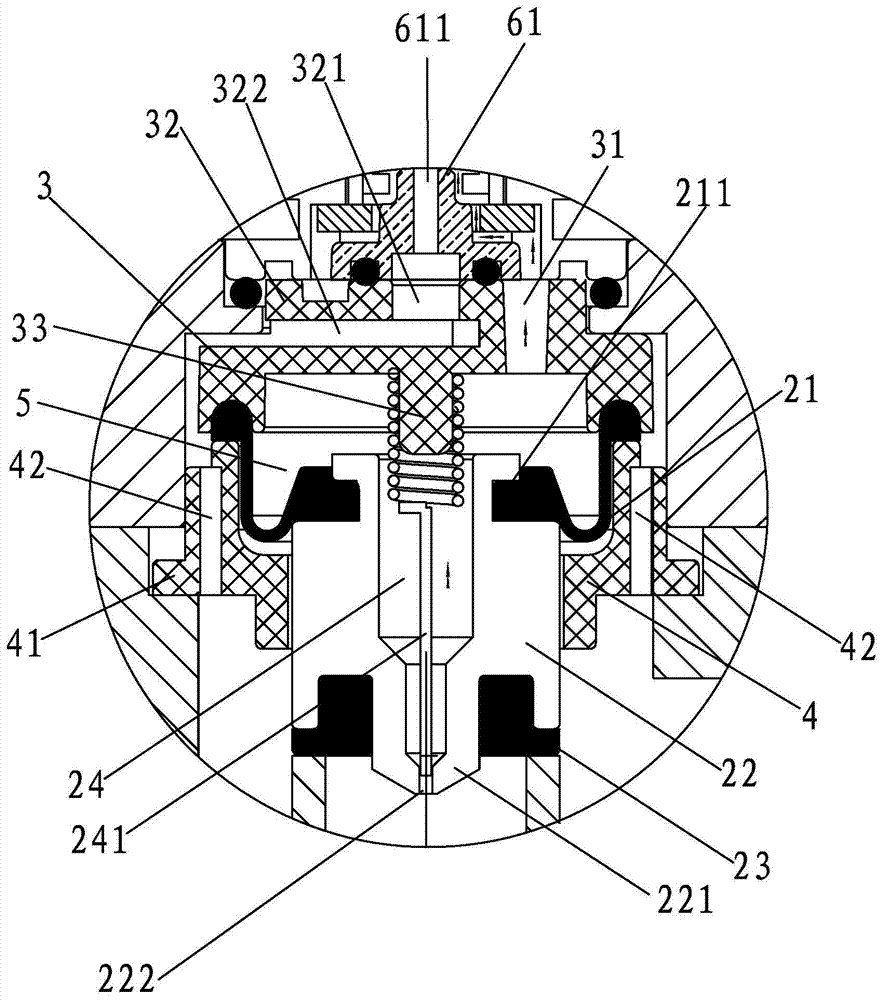

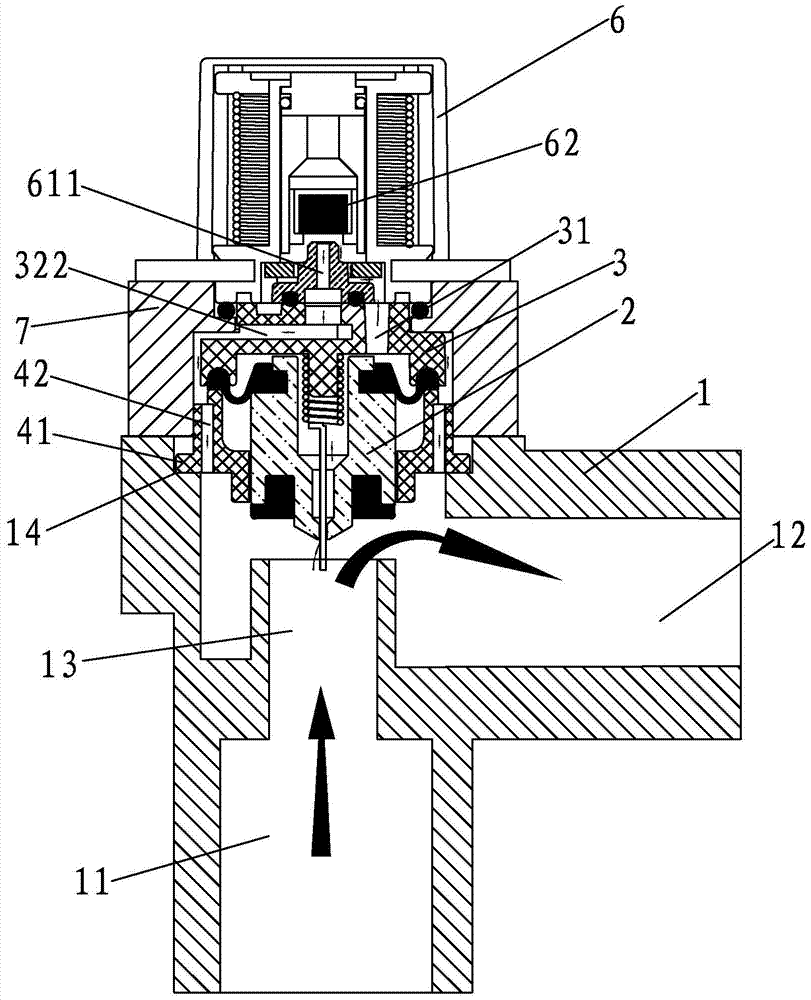

[0036] A waterway control valve structure, such as Figure 1-Figure 2 As shown, it includes a valve body 1 with a water inlet 11 and a water outlet 12, a valve core set 2 installed in the valve body 1, a diaphragm gland 3 and a shaft sleeve 4, and a water inlet 11 and a water outlet 12 are formed. There is a through hole 13 , the diaphragm gland 3 is installed above the spool set 2 , and the spool set 2 is arranged above the through hole 13 .

[0037] The spool kit 2 is composed of a rubber diaphragm 21, a spool body 22 and a water-stop rubber pad 23 from top to bottom. The spool body 22 is provided with a water inlet channel 24, and the lower part of the spool body 22 has a convex post 221. A balance hole 222 is defined at the lower end of the boss 221 , one end of the balance hole 222 communicates with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com